Chemical industrial park chemical acute poisoning risk assessment method and system

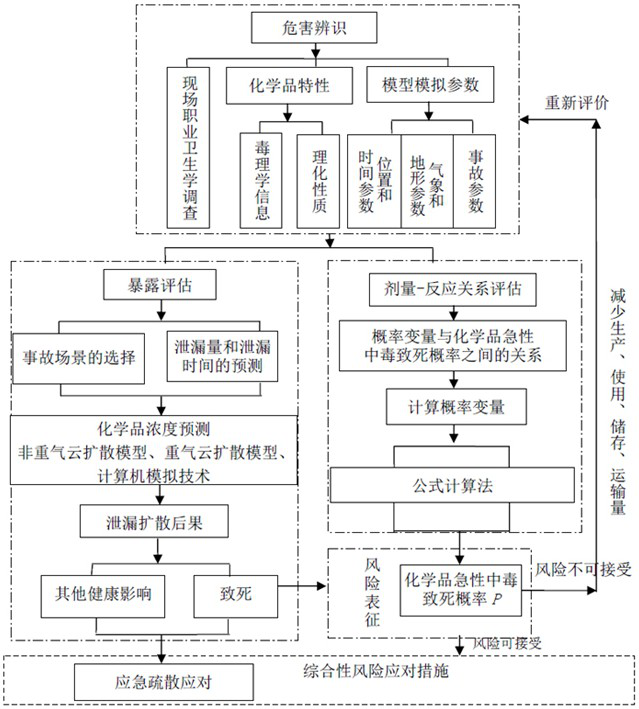

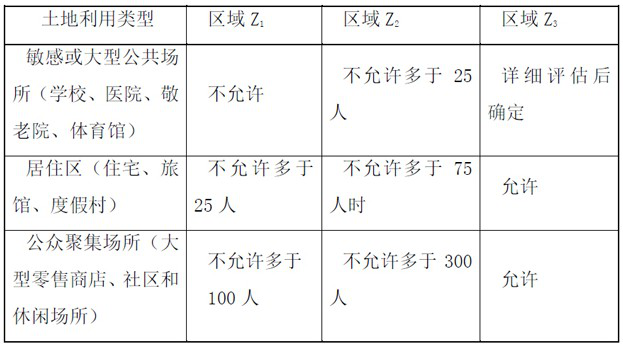

A technology for acute poisoning and chemical industry parks, applied in the fields of occupational health and occupational disease control, which can solve the problems of quantitative risk analysis, unapplied occupational health planning, layout and management of chemical industry parks, unsystematic formulation of on-site personnel treatment and on-site disposal technologies for acute chemical poisoning, undeveloped Formulate the division standard of chemical poisoning accident risk areas in chemical parks and other issues to achieve the effect of controlling occupational disease hazards, improving risk early warning and management capabilities, and preventing occupational disease hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

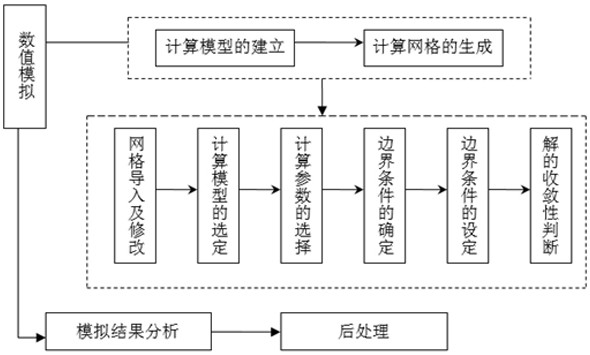

[0173] Example 1: Application Case of Diffusion Simulation of Chemical Leakage Acute Poisoning Accidents

[0174] According to the technical data, it is known that the volume of the liquid ammonia storage tank is 2m 3 , the storage capacity is 80%, placed outdoors, the working pressure is 16kg, and the design pressure is 20kg. Assuming that the ambient temperature is 20°C, an instantaneous leak occurs in which the container is destroyed, causing all the liquid to leak out.

[0175] After calculation, the leaked liquid mass W=976.48kg.

[0176] Diffusion calculation steps: judged as heavy gas-heavy gas diffusion calculation-diffusion transition point-Gaussian diffusion calculation;

[0177] 1. The percentage of liquid that evaporates directly when leaking

[0178] (G.1)

[0179] In the formula:

[0180] F——The percentage of liquid that evaporates directly when leaking;

[0181] C p ——The specific heat value of the liquid at constant pressure, in joules per kilogram Ke...

Embodiment 2

[0238] According to the technical data, it is known that the liquid chlorine gasification device, the chlorine buffer tank and the pipeline are arranged in the open air; the specification of the liquid chlorine cylinder is 1 t.

[0239] Simulate the meteorological conditions at the time of the leakage accident: the ambient temperature is 20°C, the wind speed is 4.1 m / s, the humidity is 63%, the wind speed measurement point is at a height of 10 m, the cloud coverage is 3, the atmospheric stability is B, and the temperature inversion layer does not exist .

[0240] Simulated leakage accident scenarios: complete rupture of the liquid chlorine cylinder, valve leakage; complete rupture of the chlorine buffer tank, 100% complete rupture at the connection with the pipeline, and incomplete rupture of 20% of the inner diameter of the pipeline; 100% rupture of the inner diameter of the chlorine gas delivery pipeline (rupture The hole diameter is 100% of the pipe diameter).

[0241] See...

Embodiment 3

[0244] Example 3: Application Case of Quantitative Risk Assessment for Acute Poisoning Accidents of Chemical Leakage

[0245] A fine chemical factory produces chloroformate products. Take the quantitative risk assessment of acute poisoning accidents caused by phosgene leakage in this project as an example.

[0246] Production process and raw materials

[0247] The raw and auxiliary materials used in the production process of chloroformate products mainly include coke, liquid chlorine, sodium hydroxide and various raw material alcohols. Coke and oxygen produce carbon monoxide with a purity of 99% in a carbon monoxide generator and store it in a gas cabinet. Carbon monoxide and chlorine are metered and catalyzed by activated carbon in the phosgene synthesizer to generate gaseous phosgene. Gaseous phosgene condenses into liquid phosgene and enters the liquid phosgene storage tank. The liquid phosgene is compressed into the liquefaction gasifier with compressed nitrogen for gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com