Composite neutron absorbing material and preparation method thereof

An absorbing material and composite technology, applied in the field of composite neutron absorbing materials and their preparation, can solve problems such as damage to heat dissipation capacity, and achieve the effects of improving high temperature resistance performance and mechanical strength, improving mechanical strength, and increasing absorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

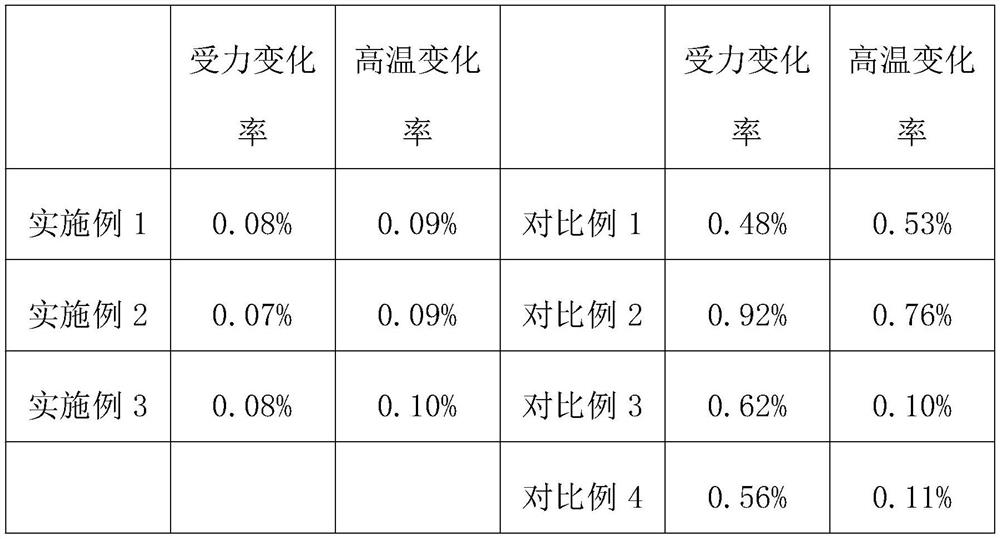

Examples

Embodiment 1

[0030] A composite neutron absorbing material mainly includes, by weight parts: 10 parts of modified carbon nano springs, 11 parts of potassium titanate whiskers and 20 parts of sodium aluminate.

[0031] A method for preparing a composite neutron-absorbing material, the method for preparing the composite neutron-absorbing material mainly includes the following preparation steps:

[0032](1) Preparation of modified carbon nanosprings: place nano-iron oxide in the reaction chamber, and at 700°C, feed nano-iron oxide 800 times the mass of acetone, pyridine and acetylene at a flow rate of 800sscm in a mass ratio of 1:1 : 3 mixed carbon source gas, stop ventilating for 5 minutes, then pass nitrogen gas at the same flow rate for 10 minutes, and after cooling to 10°C, carbon nanosprings are prepared. Carbon nanosprings and concentrated sulfuric acid with a mass fraction of 40% are pressed Mix evenly with a mass ratio of 1:15, add potassium permanganate with a mass of 0.8 times the m...

Embodiment 2

[0036] A composite neutron absorbing material mainly includes, by weight parts: 11 parts of modified carbon nano springs, 12 parts of potassium titanate whiskers and 27 parts of sodium aluminate.

[0037] A method for preparing a composite neutron-absorbing material, the method for preparing the composite neutron-absorbing material mainly includes the following preparation steps:

[0038] (1) Preparation of modified carbon nano-springs: place nano-iron oxide in the reaction chamber, and at 750°C, flow 900 times the mass of nano-iron oxide at a flow rate of 900 sscm by acetone, pyridine and acetylene in a mass ratio of 1:1 : 3 mixed carbon source gas, stop ventilating for 8 minutes, and then pass nitrogen gas at the same flow rate for 15 minutes, and after cooling to 20 ° C, carbon nano springs are obtained. Carbon nano springs and concentrated sulfuric acid with a mass fraction of 45% are pressed Mix evenly with a mass ratio of 1:12, add potassium permanganate with a mass of 0...

Embodiment 3

[0042] A composite neutron absorbing material mainly includes, by weight, 13 parts of modified carbon nano springs, 15 parts of potassium titanate whiskers and 35 parts of sodium aluminate.

[0043] A method for preparing a composite neutron-absorbing material, the method for preparing the composite neutron-absorbing material mainly includes the following preparation steps:

[0044] (1) Preparation of modified carbon nano-springs: place nano-iron oxide in the reaction chamber, and at 800°C, flow 1,000 times the mass of nano-iron oxide at a flow rate of 1,000 sscm. : 3 mixed carbon source gas, stop ventilating for 10 minutes, then pass nitrogen gas at the same flow rate for 20 minutes, and after cooling to 30 ° C, carbon nano springs are prepared. Carbon nano springs and concentrated sulfuric acid with a mass fraction of 50% are pressed Mix evenly with a mass ratio of 1:10, add potassium permanganate with 1 times the mass of carbon nano springs, and react at 60°C with 40kHz ult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com