Ceramic powder and application thereof

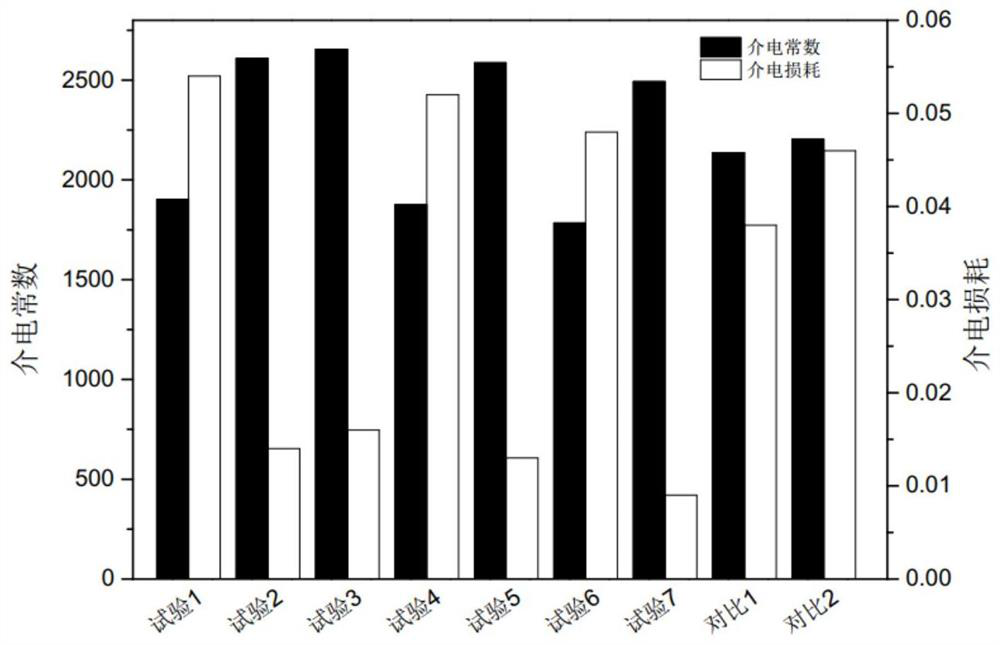

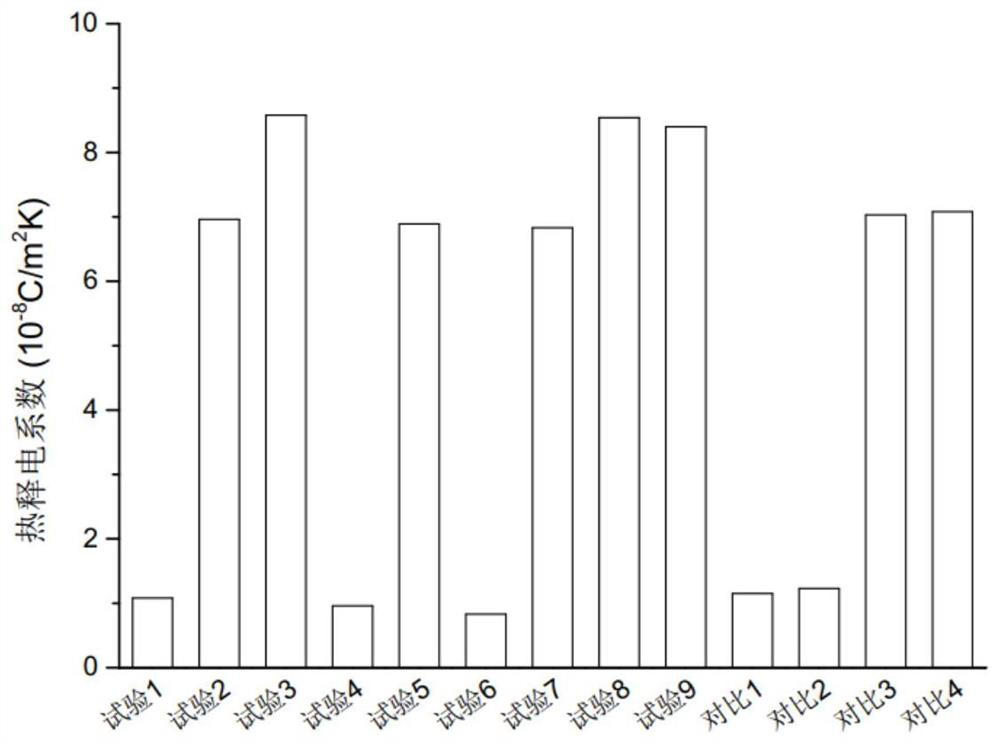

A technology of ceramic powder and general formula, applied in the field of ceramic powder, can solve the problem that it is difficult to meet the requirements of high-end electronic equipment, and achieve the effects of improving sintering and organizational structure, reducing dielectric loss and increasing dielectric constant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

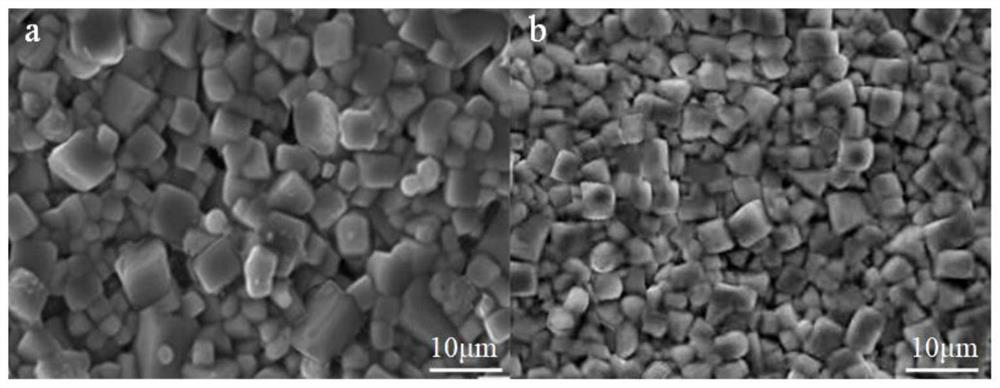

[0047] One embodiment of the present invention also provides a preparation method of ceramic powder, comprising: using a solid phase method to synthesize barium strontium titanate ceramic powder, ball milling barium carbonate, strontium carbonate, and titanium dioxide, and sintering to obtain barium strontium titanate ceramic powder . In the preparation method of this embodiment, the barium strontium titanate ceramic powder is synthesized by a solid-state method, and the prepared ceramic powder has a higher constant and a lower dielectric loss.

[0048] In one embodiment of the present invention, a method for preparing ceramic powder doped with lutetium oxide and scandium oxide includes:

[0049] --Weigh barium carbonate, strontium carbonate and titanium dioxide in proportion, ball mill for 24-48 hours, and sinter at 950-1100°C for 2-5 hours to obtain barium strontium titanate ceramic powder;

[0050] --The barium strontium titanate ceramic powder, lutetium oxide and scandium...

Embodiment 1

[0075] A kind of ceramic powder, its general chemical formula is Ba 0.15 Sr 0.25 TiO 3 , and its preparation method comprises: weighing barium carbonate, strontium carbonate and titanium dioxide in proportion, ball milling for 24 hours, and sintering at 1000° C. for 4 hours to obtain barium strontium titanate ceramic powder.

Embodiment 2

[0077] A kind of ceramic powder, it is Ba doped with 0.1mol% lutetium oxide and 0.016mol% scandium oxide 0.15 Sr 0.25 TiO 3 Ceramic powder, its preparation method, comprises:

[0078] --Weigh barium carbonate, strontium carbonate and titanium dioxide in proportion, ball mill for 24 hours, and sinter at 1000°C for 4 hours to obtain barium strontium titanate ceramic powder;

[0079] --Ball-mill the barium strontium titanate ceramic powder, lutetium oxide and scandium oxide for 24 hours for the second time, and sinter for 3 hours at 1440°C to obtain the ceramic powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com