Polycarboxylate-type efficient dust suppressant as well as preparation method and application thereof

A technology of polycarboxylate and dust suppressant, applied in chemical instruments and methods, and other chemical processes, can solve the problems of difficult wetting, effective permeability, short effective dust suppression cycle, slow crusting, etc., and achieve anti-compression High strength, long-lasting dust suppression, and the effect of reducing cumbersomeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

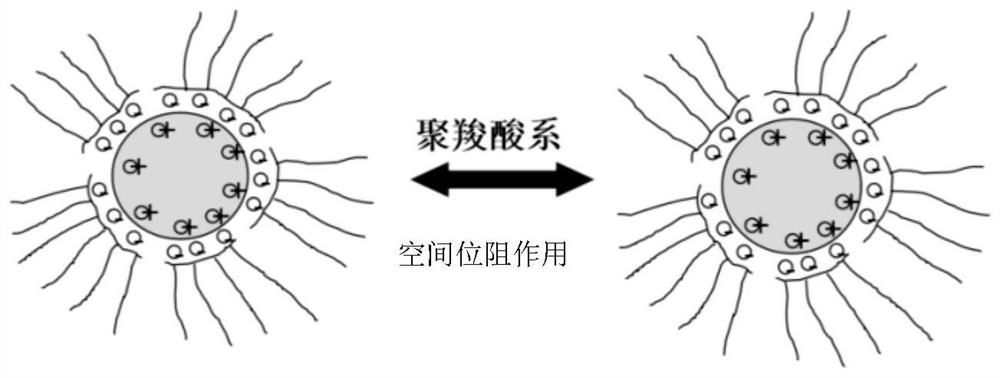

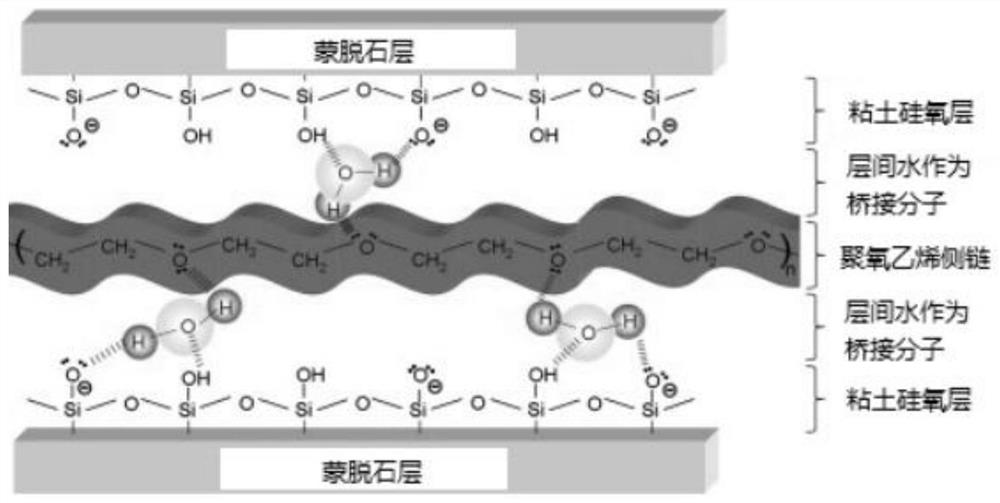

Method used

Image

Examples

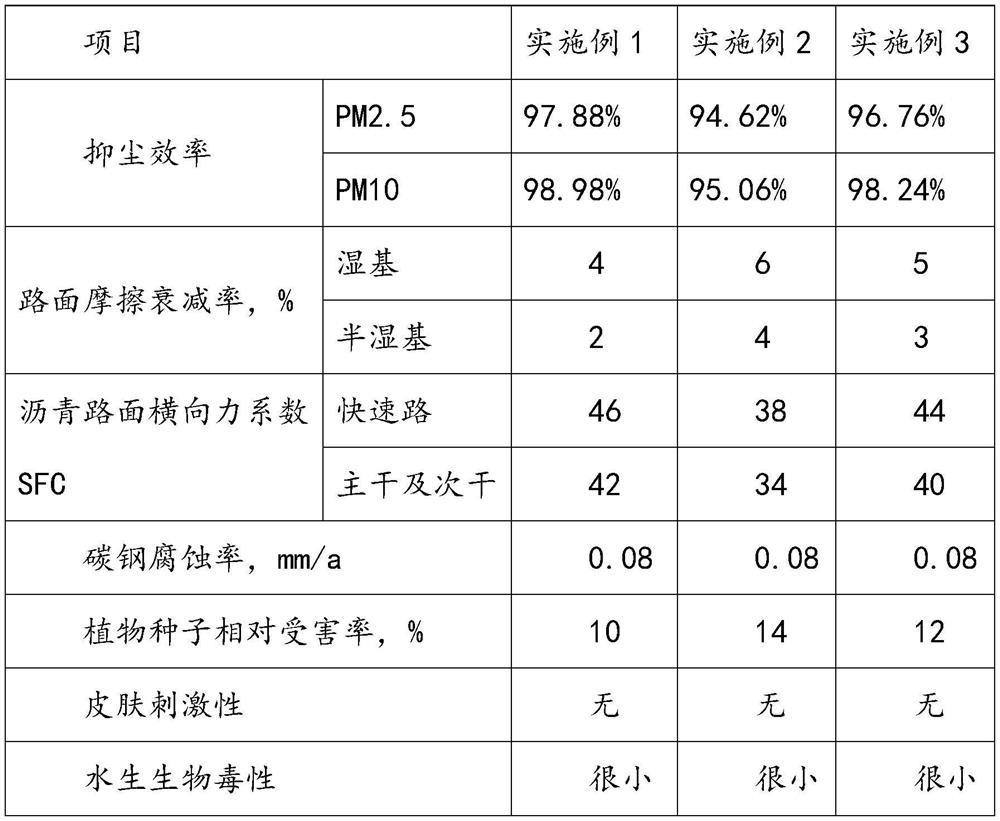

Embodiment 1

[0034] Polycarboxylate high-efficiency dust suppressant, composed of 70 parts of polycarboxylic acid copolymer, 10 parts of polyvinyl alcohol, 10 parts of carboxymethyl starch, and 0.8 parts of preservative. The dust suppression effect test was carried out after the dust suppression agent was diluted with water at a mass ratio of 1:9.

Embodiment 2

[0036] Polycarboxylate high-efficiency dust suppressant, composed of 70 parts of polycarboxylic acid copolymer, 10 parts of sodium lauryl sulfate, 10 parts of carboxymethyl starch, and 0.8 parts of preservative. The dust suppression effect test was carried out after the dust suppression agent was diluted with water at a mass ratio of 1:9.

Embodiment 3

[0038]Polycarboxylate high-efficiency dust suppressant, composed of 70 parts of polycarboxylic acid copolymer, 10 parts of polyvinyl alcohol, 10 parts of sodium lauryl sulfate, and 0.8 parts of preservative. The dust suppression effect test was carried out after the dust suppression agent was diluted with water at a mass ratio of 1:9.

[0039] According to T / CAEPI 7-2017 "Water-Soluble Road Dust Suppressant" standard, the performance test results are as follows:

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com