Moringa oleifera polysaccharide composition, daily necessities and preparation method and application thereof

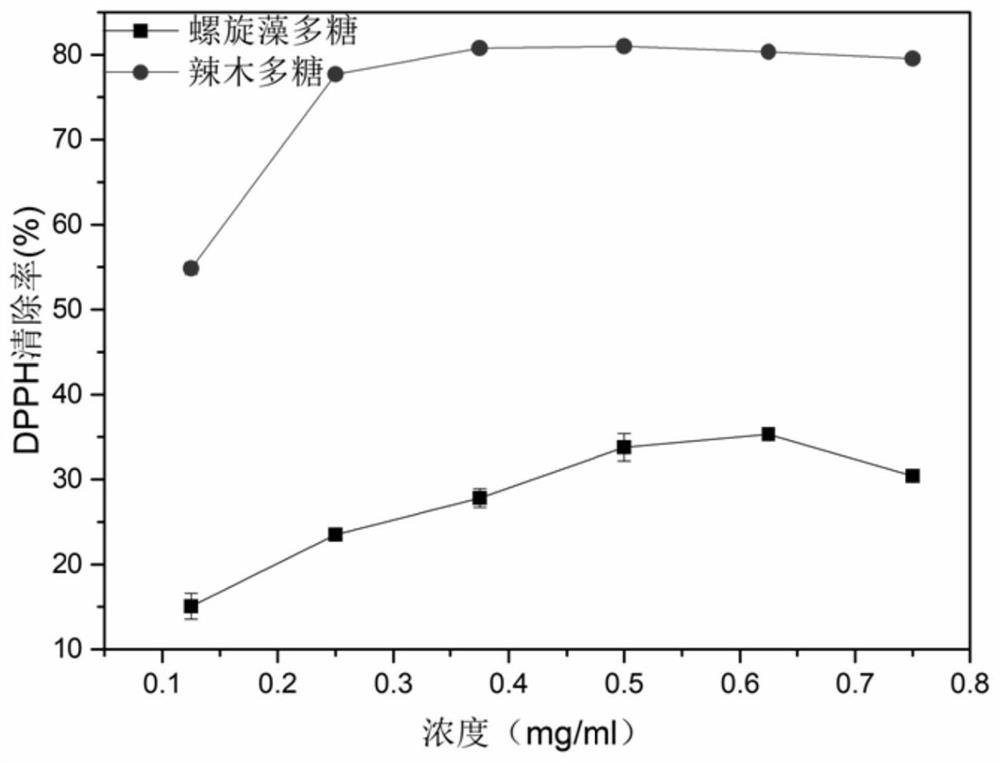

A technology of Moringa polysaccharide and composition, applied in the field of Moringa polysaccharide composition, can solve problems such as single efficacy, poor skin care effect, etc., and achieve the effects of easy operation, improved antioxidant repair effect, and good moisturizing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

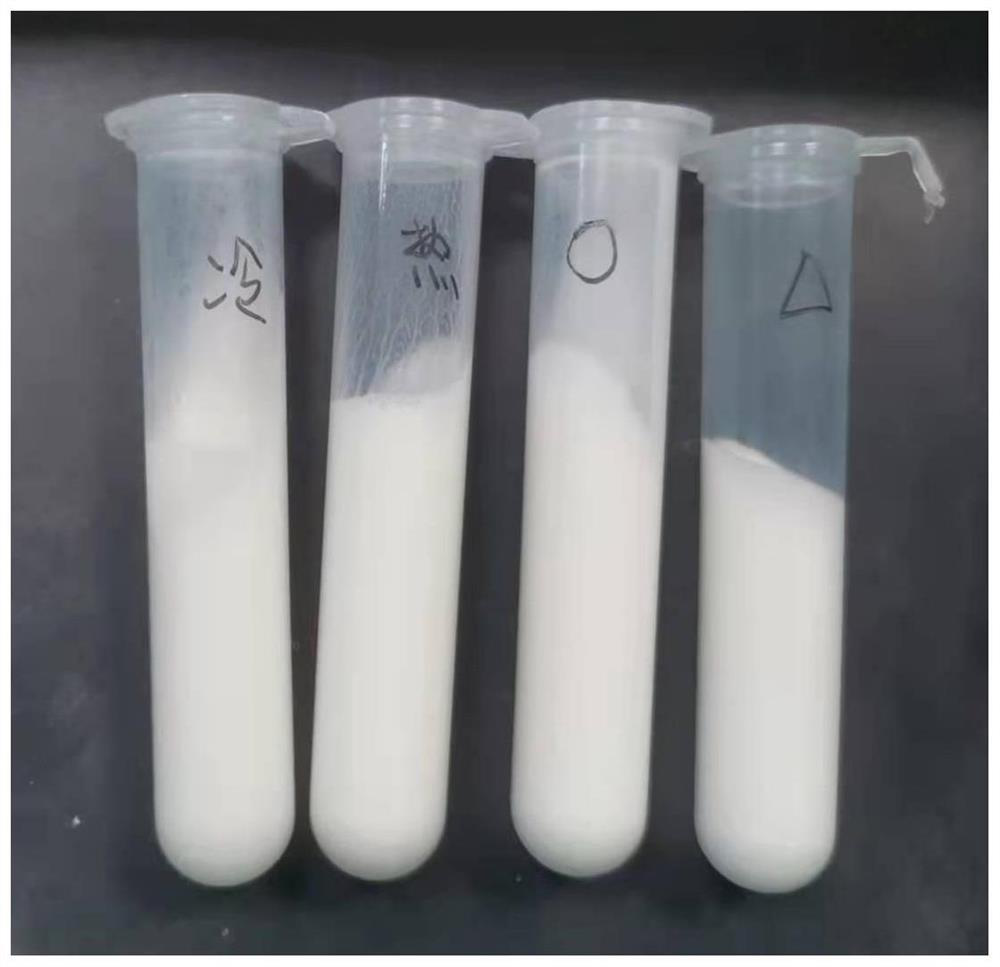

Image

Examples

Embodiment 1

[0040] Example 1: Preparation of Moringa polysaccharide powder

[0041] 1. Extract:

[0042]Weigh 10.00g of Moringa oleifera powder in a 500ml beaker, add deionized water to the beaker at a material-to-liquid ratio of 1:20 (g / ml), and sonicate for 20min at 40KHz. After ultrasonication, refluxed at 80 °C for 1.5 h, the extract was centrifuged at 4000 r / min for 10 min, and the supernatant was taken. The precipitation was transferred to continue leaching, and the operation was repeated 3 times. The extract was concentrated under reduced pressure at 70°C to obtain a concentrated solution. Then use 5 times the volume of the concentrated solution for alcohol precipitation overnight, centrifuge at 4000 r / min for 10 min, and take the precipitate. -40°C vacuum freeze-drying to obtain crude polysaccharide precipitation.

[0043] 2. Decolorization:

[0044] The crude polysaccharide precipitate was dissolved in ultrapure water into a solution, 30% hydrogen peroxide was added to it ac...

Embodiment 2

[0045] Example 2: Preparation of Spirulina Polysaccharide Powder

[0046] 1. Extraction

[0047] Weigh 10.00g of Spirulina powder in a 500ml beaker, add deionized water to the beaker at a solid-liquid ratio of 1:20 (g / ml), freeze at -20°C for 4h, and take out. Then thawed in a water bath at 37°C, repeated 3 times, and sonicated at 40KHz for 20min. After ultrasonication, refluxed at 80 °C for 1.5 h, the extract was centrifuged at 4000 r / min for 10 min, and the supernatant was taken. The precipitation was transferred to continue leaching, and the operation was repeated 3 times. The extract was concentrated under reduced pressure at 70°C to obtain a concentrated solution. Then use 5 times the volume of the concentrated solution for alcohol precipitation overnight, centrifuge at 4000 r / min for 10 min, and take the precipitate. -40°C vacuum freeze-drying to obtain crude polysaccharide precipitation.

[0048] 2. Decolorization

[0049] The crude polysaccharide precipitate was ...

Embodiment 3

[0050] Example 3: Preparation of cream

[0051] 1. Raw materials

[0052] Tocopheryl acetate: purchased from the website of Making Cosmetics (trade name: Vitamin E (dl-alphatocopheryl acetate), glyceryl stearate-polyethylene glycol-100 stearate mixture: from the website of Making Cosmetics (trade name of dl-alphatocopheryl acetate) BLEND), sodium acrylate / sodium acryloyl dimethyl taurate copolymer-isohexadecane-polysorbate 80 blend: available from the Making Cosmetics website (trade name GelmakerEMU), jojoba oil: available from Mike Lin (trade name Jojoba Oil), Shea Butter: purchased from Making Cosmetics website (trade name Shea Butter, Certified Organic), Sweet Almond Oil: purchased from Huaxin Company (trade name Sweet almondoil), Glycerin: purchased from Sinopharm Chemical Reagent Co., Ltd., sodium pyrrolidone carboxylate: purchased from Yuanye Bio, ethylenediaminetetraacetic acid (EDTA): purchased from Merrill, xanthan gum: purchased from Ailan (Shanghai) Chemical Techn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com