Water-based zinc-based secondary battery with high energy density and long cycle life

A zinc-based secondary battery, high energy density technology, applied in secondary batteries, battery electrodes, aqueous electrolytes, etc., can solve the problem of poor cycle life of aqueous secondary zinc-based batteries, narrow electrochemical window of electrolyte, and limited battery energy Density and other issues, to achieve high thermodynamic stability, ease the formation of zinc negative electrode dendrites and hydrogen evolution reaction, and improve the effect of negative electrode Coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

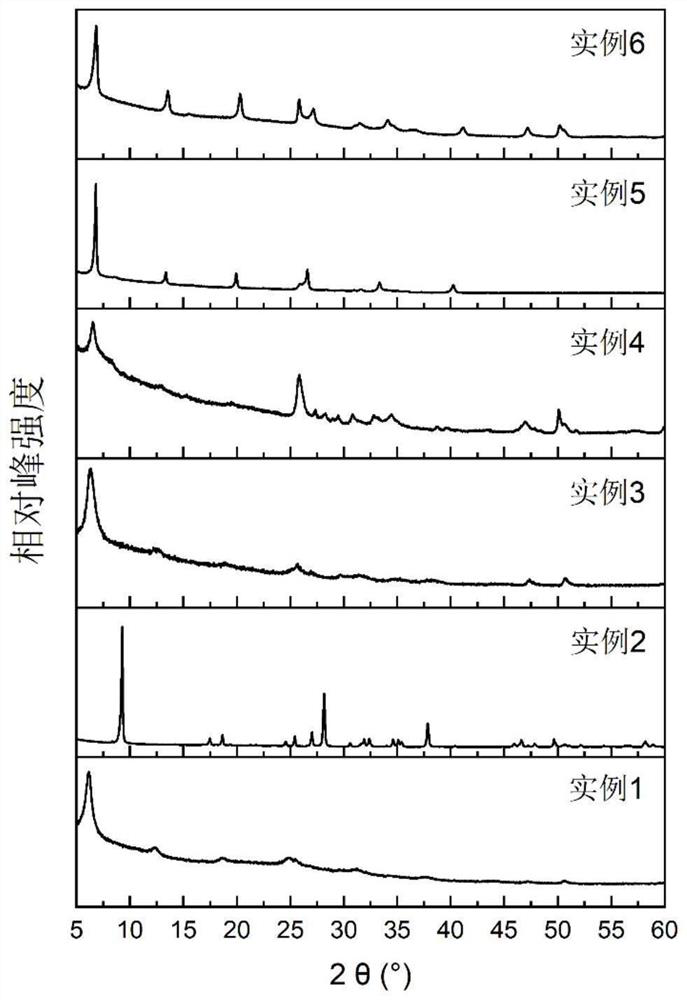

[0044] (1) The layered structure V 2 O 5 ·nH 2 O positive electrode active material, conductive agent acetylene black and binder polytetrafluoroethylene (PTFE) were mixed in a mass ratio of 70:20:10 and dispersed in N-methylpyrrolidone (NMP) to prepare a slurry, and the slurry was rolled out. Pressed into a self-supporting film, dried and cut into a positive electrode sheet;

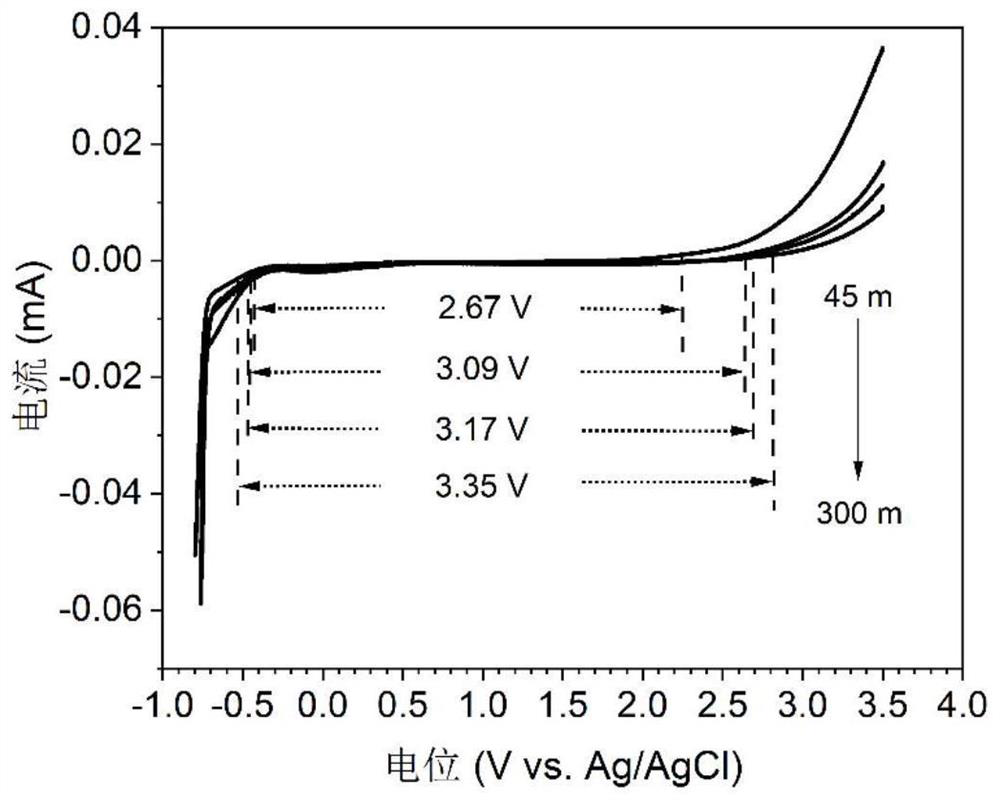

[0045] (2) dissolving zinc chloride and choline chloride in deionized water, and configuring it into an electrolyte having a molar concentration of 45 m according to a molar concentration (m) ratio of 2:1;

[0046] (3) Cut a metal zinc foil with a thickness of 10 μm and a purity of 99% into a suitable size matching the positive electrode to make a negative electrode sheet;

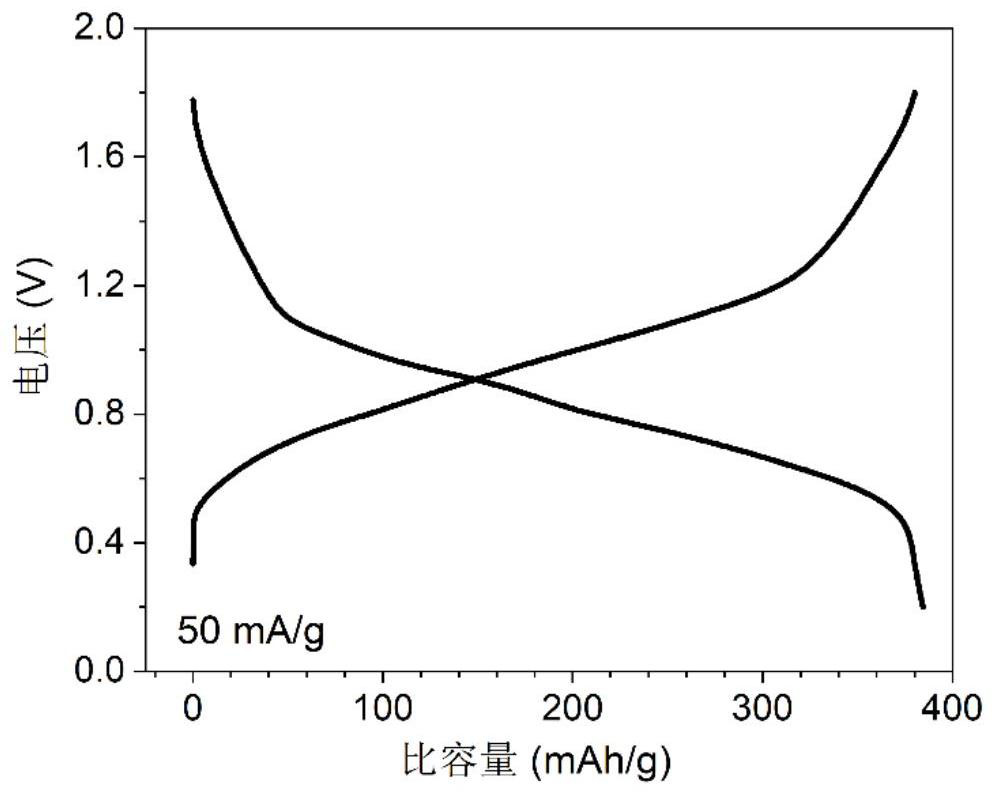

[0047] (4) Separating the above-prepared positive electrode sheet and negative electrode sheet with a glass fiber membrane separator, putting it into a battery case, and then injecting an electrolyte solution to encapsulate the ba...

Embodiment 2

[0049] (1) The layered structure K 0.25 V 2 O 5 ·nH 2 O positive active material, conductive agent Ketjen black and binder vinylidene fluoride (PVDF) are mixed in a mass ratio of 70:10:10 and dispersed in NMP to prepare a slurry, which will be coated on the carbon paper current collector, After drying, it is cut into a positive electrode sheet;

[0050] (2) zinc chloride and choline chloride are dissolved in deionized water, according to mass molar concentration ratio 2:1, be configured into the electrolyte that mass molar concentration is 60m;

[0051] (3) Cut a metal zinc foil with a thickness of 20 μm and a purity of 99.9% into a suitable size matching the positive electrode to make a negative electrode sheet;

[0052] (4) The above-prepared positive electrode sheet and negative electrode sheet are separated by a non-woven diaphragm, put into a battery case, and then injected with an electrolyte solution to encapsulate the battery to obtain an aqueous zinc-based seconda...

Embodiment 3

[0054] The layered structure Co 0.20 V 2 O 5 ·nH 2 O positive active material, conductive agent Ketjen black and binder PVDF are mixed in a mass ratio of 80:10:10 and dispersed in NMP to prepare a slurry, which will be coated on the carbon paper current collector, dried and cut to make positive plate;

[0055] (2) zinc chloride and choline chloride are dissolved in deionized water, according to mass molar concentration ratio 2:1, be configured into the electrolyte that mass molar concentration is 90m;

[0056] (3) Cut a metal zinc foil with a thickness of 20 μm and a purity of 99.99% into a suitable size matching the positive electrode to make a negative electrode sheet;

[0057] (4) Separating the above-prepared positive electrode sheet and negative electrode sheet with a glass fiber membrane separator, putting it into a battery case, and then injecting an electrolyte solution to encapsulate the battery to obtain an aqueous zinc-based secondary battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com