A preparation method of a high-transmission and high-corrosion coating suitable for high-frequency printed antennas

An anti-corrosion coating and antenna technology, applied in the structural form of the radiating unit, the structural form of the radiating element, etc., can solve the problems of the large influence of the transmission index and the inability to meet the transmission performance of high-frequency electromagnetic waves at the same time, and achieve high environmental corrosion resistance, Scientifically designed, cleverly conceived effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] A method for preparing a high-transmittance and high-corrosion coating suitable for high-frequency printed antennas comprises using liquid hexafluoropropane as a coating and 1,1-diphenyl-2-trinitrophenylhydrazine as a polymerization inhibitor; The method includes the following steps:

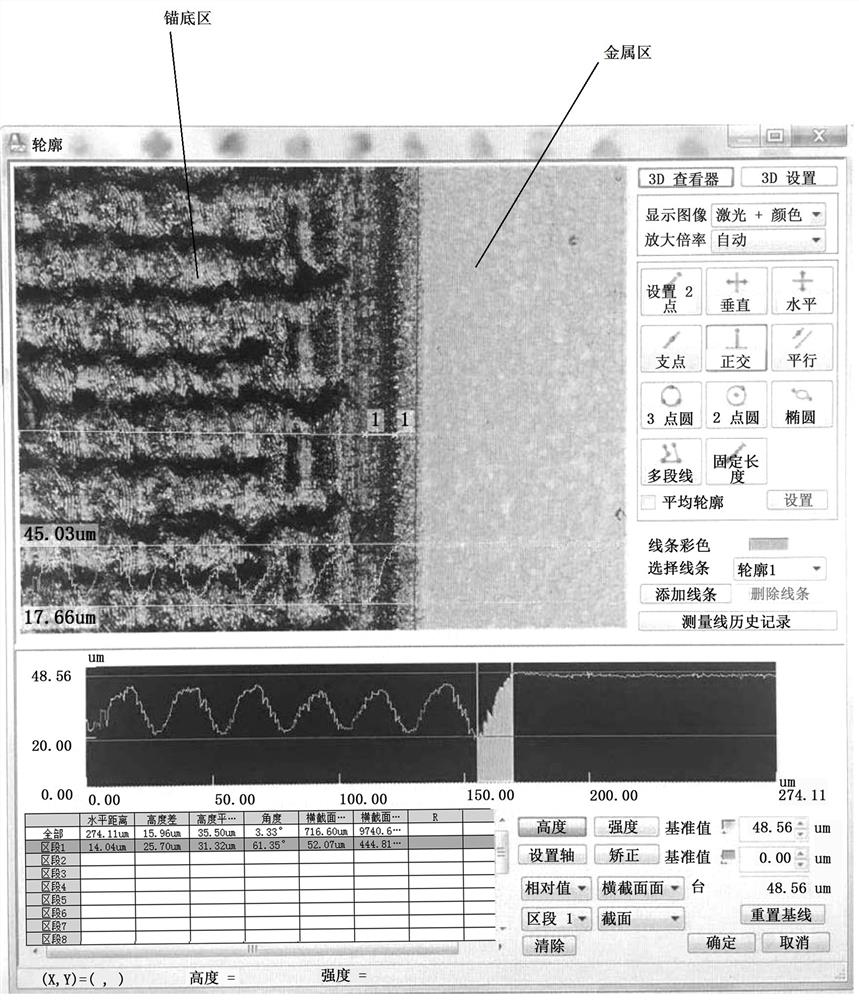

[0062] S1. Laser anchor base: use laser to process the microstructure on the coating surface of the high-frequency printed antenna, as the anchor base for the fluorocarbon coating;

[0063] S2. Plasma-enhanced chemical vapor deposition: Using plasma chemical vapor deposition, hexafluoropropane is deposited on the surface of the high-frequency printed antenna after S1 treatment to form a fluorocarbon coating;

[0064] S3. Residual free radical control: inject vaporized 1,1-diphenyl-2-trinitrophenylhydrazine into the vacuum chamber, capture free radicals, prevent polymer chain reaction, and complete the preparation process of fluorocarbon coating .

[0065] Preferably, the microstructure ...

Embodiment 1

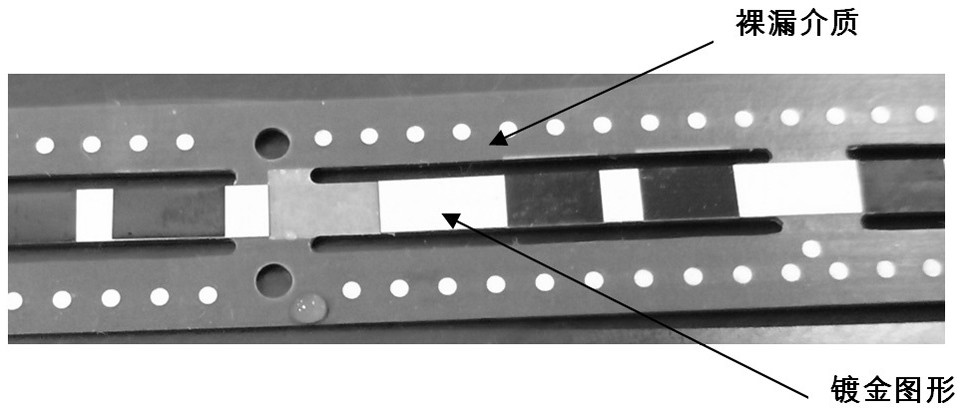

[0093] The present embodiment discloses a method for preparing a high-transmittance and high-anti-corrosion coating of a high-frequency printed antenna. The high-frequency printed antenna substrate used in this embodiment is as attached figure 1 shown. The surface of the material consists of two parts, one part is a metal pattern and the other part is a medium. Among them, the metal pattern material is copper gold plating, and the dielectric material is PTFE glass fiber composite material.

[0094] S1. Laser anchor bottom, its principle is as attached Figure 5 shown;

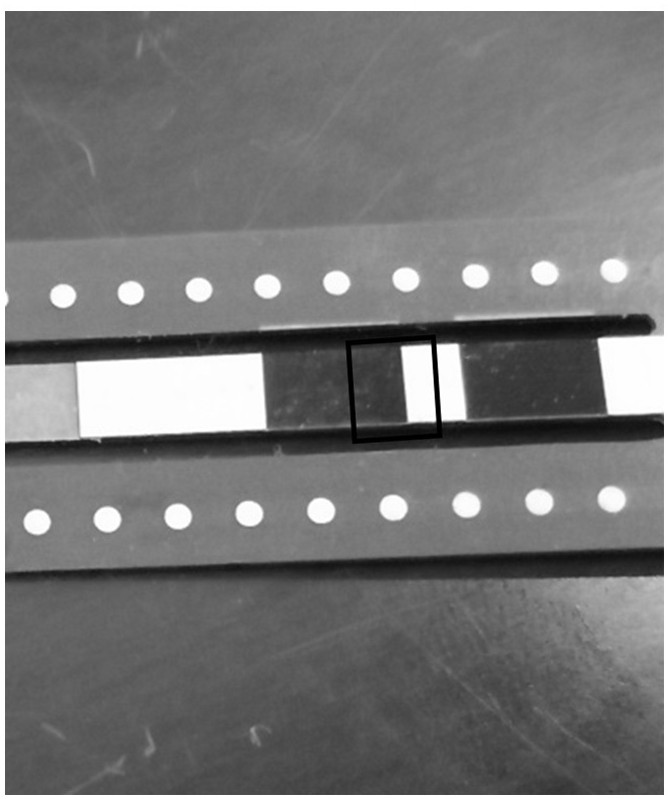

[0095] After cleaning the surface of the antenna with absolute ethanol, use the image recognition device of the laser processing equipment to accurately divide the area where the PTFE glass fiber composite material is located, as shown in the attachment. image 3 shown.

[0096] like Figure 4 As shown, according to the working frequency band of the high-frequency printed antenna and the environmental cor...

Embodiment 2

[0121] Compared with Embodiment 1, this embodiment differs in that the parameters of step S2 and step S3 are different, and other conditions are the same.

[0122] S21. The chamber is heated to 60°C and kept for 20min;

[0123] S22. The chamber is evacuated to -10Pa;

[0124] S23. After the liquid hexafluoropropane is vaporized by the ultrasonic vaporization device, it is injected into the vacuum chamber, the flow rate is 100sccm, the time is 8min, and the chamber temperature is kept at 100℃;

[0125] S24. Input voltage 100V, current 10A, discharge time 8min.

[0126] S3. Residual Radical Control

[0127] The vaporized polymerization inhibitor 1,1-diphenyl-2-trinitrophenylhydrazine solution was injected, the flow rate was 30 sccm, the chamber temperature was 60 °C, and the time was 5 min.

[0128] The performance test of the fluorocarbon coating prepared in this example is carried out, and the test method is the same as that of Example 1.

[0129] The results show that the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com