Long-life polyurethane acrylic coating and preparation method thereof

A technology of urethane acrylic acid and urethane acrylate, applied in the field of long-life urethane acrylic coating and its preparation, can solve the problems of poor weather resistance, poor corrosion resistance and poor weather resistance of acrylic resin, and achieve enhanced corrosion resistance, good weather resistance and excellent acid corrosion resistance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

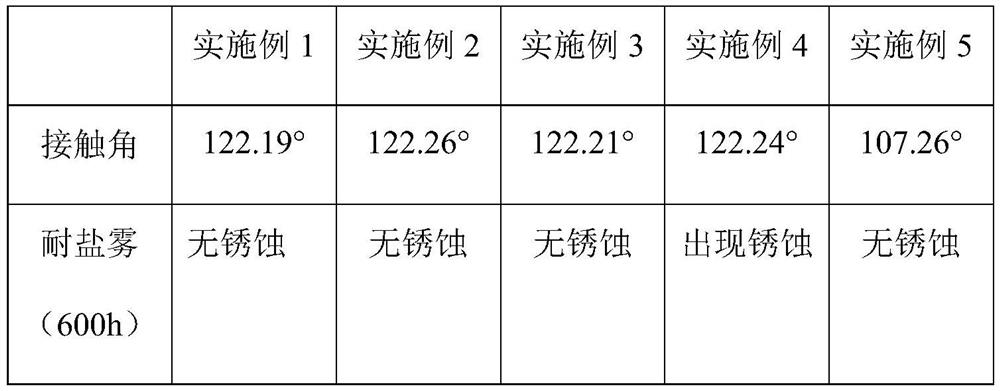

Examples

Embodiment 1

[0029] Step 1: Preparation of modified graphene oxide:

[0030] Aniline-p-phenylenediamine copolymer:

[0031] 7 parts of aniline, 24 parts of p-phenylenediamine, 0.7 parts of octylphenol polyoxyethylene ether, 100 ml of hydrochloric acid, stirred for 25 minutes, 1.5 parts of ammonium persulfate was dissolved in hydrochloric acid, added dropwise to the reaction system with stirring, suction filtered, washed When the filtrate is neutral, remove impurities, wash, and dry at 42°C for 48h to obtain aniline-p-phenylenediamine copolymer.

[0032] Synthesis of Quinoline Acrylate:

[0033] Dissolve 50g of 8-hydroxyquinoline and 56ml of triethylamine in 300ml of anhydrous chloroform, mix well at -1°C, add 30ml of acryloyl chloride dropwise, react at -1°C for 11h under a nitrogen atmosphere, filter under vacuum, Wash, add sodium sulfate, filter, and purify to give quinoline acrylate.

[0034] Synthesis of 8-hydroxyquinoline-aniline-p-phenylenediamine copolymer:

[0035] Take 3g of a...

Embodiment 2

[0048] Step 1: Preparation of modified graphene oxide:

[0049] Aniline-p-phenylenediamine copolymer:

[0050] 5 parts of aniline, 15 parts of p-phenylenediamine, 0.6 part of octylphenol polyoxyethylene ether, 100 ml of hydrochloric acid, stirred for 20 minutes, 0.5 part of ammonium persulfate was dissolved in hydrochloric acid, added dropwise to the reaction system with stirring, suction filtered, Wash until the filtrate is neutral, remove impurities, wash, and dry at 40° C. for 46 hours to obtain aniline-p-phenylenediamine copolymer.

[0051] Synthesis of Quinoline Acrylate:

[0052] Dissolve 50g of 8-hydroxyquinoline and 56ml of triethylamine in 300ml of anhydrous chloroform, mix well at -2°C, add 30ml of acryloyl chloride dropwise, react at -2°C for 10h under nitrogen atmosphere, filter under vacuum, Wash, add sodium sulfate, filter, and purify to give quinoline acrylate.

[0053] Synthesis of 8-hydroxyquinoline-aniline-p-phenylenediamine copolymer:

[0054] Take 3g of...

Embodiment 3

[0067] Step 1: Preparation of modified graphene oxide:

[0068] Aniline-p-phenylenediamine copolymer:

[0069] 10 parts of aniline, 30 parts of p-phenylenediamine, 0.8 part of octylphenol polyoxyethylene ether, 100 ml of hydrochloric acid, stirred for 30 min, 2 parts of ammonium persulfate was dissolved in hydrochloric acid, added dropwise to the reaction system with stirring, suction filtered, Wash until the filtrate is neutral, remove impurities, wash, and dry at 44°C for 50h to obtain aniline-p-phenylenediamine copolymer.

[0070] Synthesis of Quinoline Acrylate:

[0071] Dissolve 50g of 8-hydroxyquinoline and 56ml of triethylamine in 300ml of anhydrous chloroform, mix well at 0°C, add 30ml of acryloyl chloride dropwise, react at 0°C for 12h under a nitrogen atmosphere, filter under vacuum, wash, Sodium sulfate was added, filtered and purified to give quinoline acrylate.

[0072] Synthesis of 8-hydroxyquinoline-aniline-p-phenylenediamine copolymer:

[0073] Take 3g of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com