Method for instantaneous high-temperature synthesis of transition metal carbide nano array by taking oxide as template

A transition metal and nano-array technology, applied in electrolysis process, electrolysis components, electrodes, etc., can solve the problems of long process time, difficult control of carbide morphology and size, high energy consumption, etc., and achieve a unique level, electron migration and transmission The effect of convenient quality and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for instantaneous high-temperature synthesis of molybdenum carbide nanoarrays using oxides as templates, comprising the following steps:

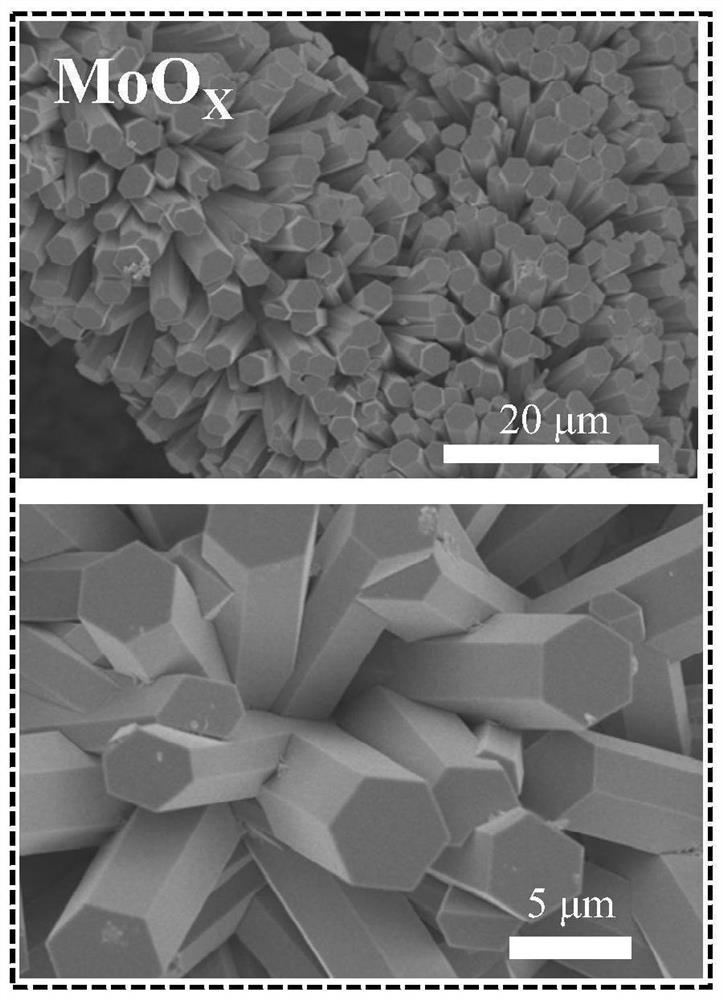

[0045] (1) Molybdenum oxide (MoO) with nano-array structure was grown on carbon cloth substrate by hydrothermal method X ), the hydrothermal reaction precursor solution 5mL HNO 3 , 70mL H 2 O, 2.5g (NH 4 ) 6 Mo 7 O 24 ·4H 2 After the O was mixed evenly, carbon was placed in it and reacted at 150 °C for 10 min, and then the carbon cloth was taken out, washed, and dried at 60 °C to obtain molybdenum oxide nanoarrays;

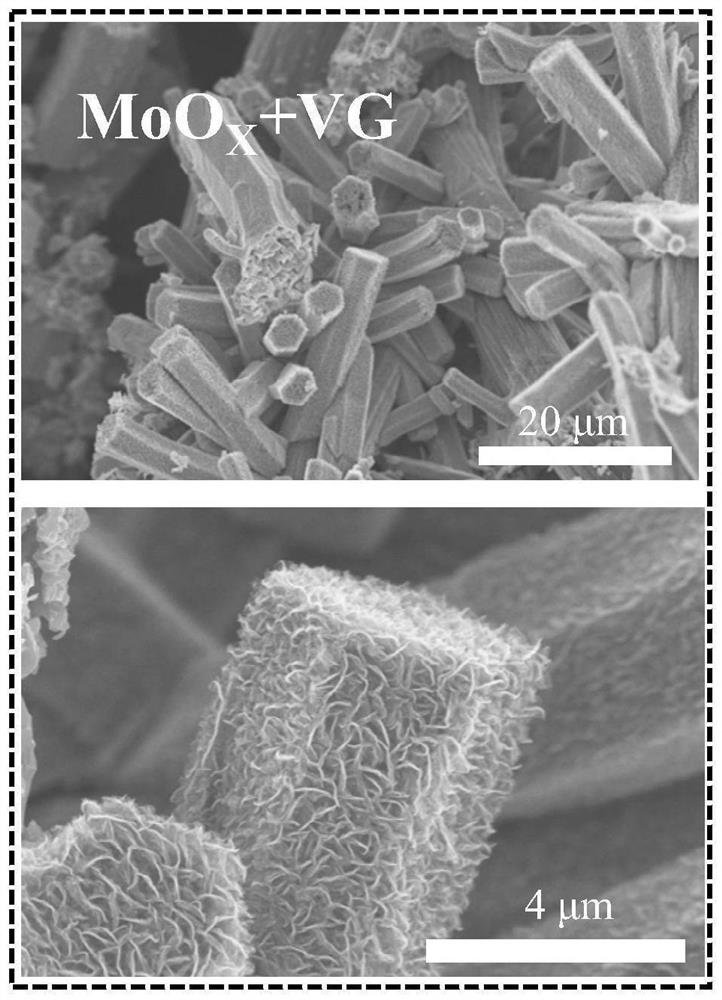

[0046](2) Using the molybdenum oxide nanoarrays supported on carbon cloth as the substrate, the vertical graphene nanosheets (VG) were deposited on the surface by plasma-assisted chemical vapor deposition method, and the process parameters were: Ar, H 2 and CH 4 The flow rates were 20, 10 and 7sccm, the deposition time was 12min, the temperature used was 600°C, and the power of the plasma equipment was 6...

Embodiment 2

[0049] A method for instantaneous high-temperature synthesis of cobalt carbide nanoarrays using oxide as a template, comprising the following steps:

[0050] (1) Cobalt tetroxide (Co3O4) with nano-array structure was grown on carbon cloth substrate by hydrothermal method 3 O 4 ), the hydrothermal reaction precursor solution 70mL deionized water, 2g Co(NO 3 ) 2 , 0.7g NH 4 F. 0.25g Co(NH 2 ) 2 After mixing evenly, the carbon was placed in it and reacted at 115°C for 9 hours, then the carbon cloth was taken out, washed, dried at 60°C, and then calcined at 350°C for 2 hours in an air atmosphere to obtain cobalt oxide nanoarrays;

[0051] (2) Using the cobalt tetroxide nanoarrays supported on carbon cloth as the substrate, the vertical graphene nanosheets (VG) were deposited on the surface by plasma-assisted chemical vapor deposition method, and the process parameters were: Ar, H 2 and CH 4 The flow rates were 10, 5 and 1 sccm, the deposition time was 20 min, the temperatur...

Embodiment 3

[0054] A method for instantaneous high-temperature synthesis of tungsten carbide nanoarrays using oxide as a template, comprising the following steps:

[0055] (1) Preparation of tungsten oxide (WO) by electrodeposition on clean carbon cloth 3 ) seed layer, 0.8 g of sodium tungstate and 2.7 mL of hydrogen peroxide were added to 200 mL of deionized water, the pH was adjusted to 1.2 by adding perchloric acid, and a silver / silver chloride (Ag / AgCl) reference electrode was used. , through constant voltage (-0.7V) deposition for 400s, the carbon cloth loaded with seeds was obtained;

[0056] (2) 2.5g oxalic acid, 3g Na of the hydrothermal reaction precursor 2 WO 4 Dissolve in deionized water to form a clear solution, then add 275 μL of concentrated nitric acid, and dilute the solution to 350 mL, then take 55 mL of the solution and add 4 g of ammonium sulfate to it, then stir until clarification, then put into the reaction kettle, and load the The seeded carbon cloth was also put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com