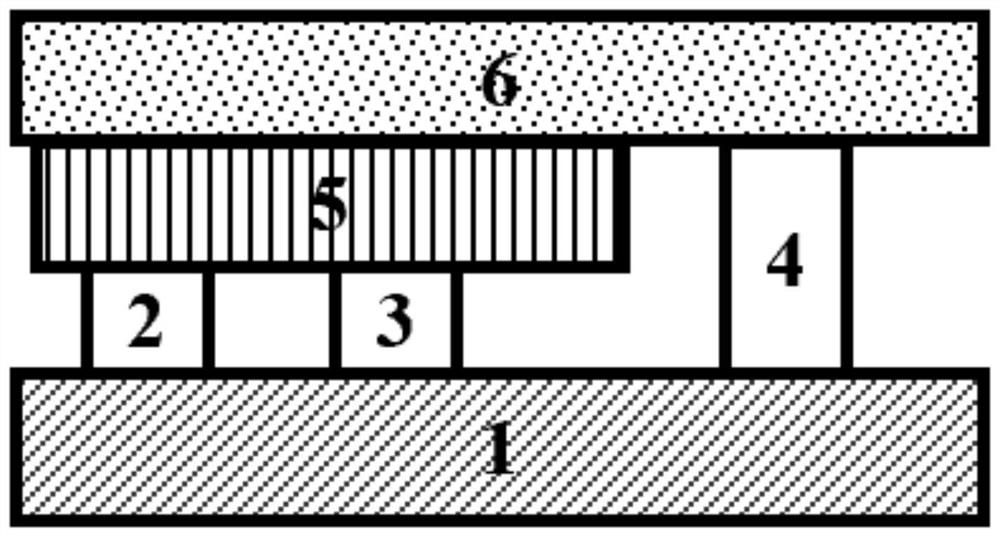

All-solid-state organic electrochemical transistor and preparation method thereof

An all-solid-state, transistor technology, used in semiconductor/solid-state device manufacturing, electric solid-state devices, circuits, etc., can solve the problems of inconvenient large-scale integration, long-term application and portability of devices, avoid inconvenient storage and application, and increase contact. area, enhancing the effect of electrochemical doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1 (control group):

[0038] 1. Clean the transparent glass substrate with a surface roughness of less than 1nm, and dry it in an incubator for more than 6 hours after cleaning;

[0039] 2. Coat a layer of detergent on the glass substrate, pour the PU on the glass substrate coated with detergent, vibrate slightly, spread the solution, and place it in a vacuum drying oven to dry (30°C, 12h), carefully peel off the flexible substrate from the glass substrate with a blade after drying;

[0040] 3. Spray the electrode of carbon paste (80-150nm) on the PU substrate;

[0041] 4. Clean the microscope slides with surface roughness less than 1nm, and dry them in an incubator for more than 6 hours after cleaning;

[0042] 5. Spin-coat the prepared PVA solution on a microscope slide (3000rpm, 60s), and dry the spin-coated slide (110°C, 2min) to obtain a PVA sacrificial layer;

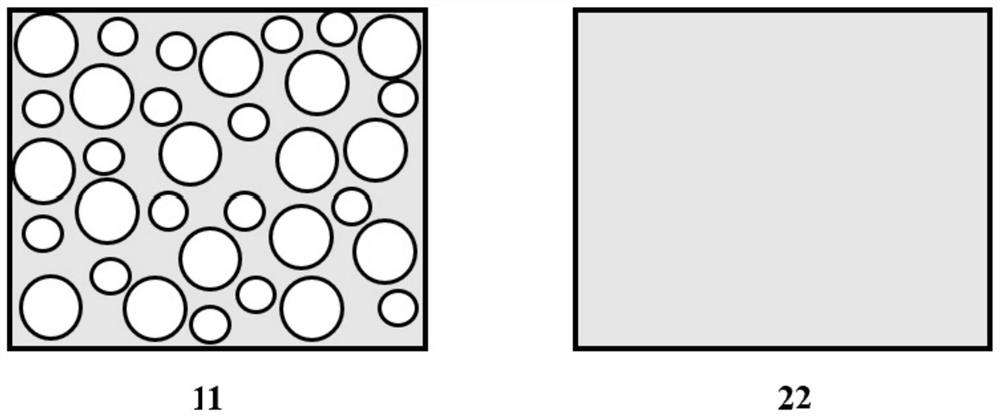

[0043] 6. Under the condition of humidity of 10%RH, spin-coat the prepared P3HT mixed solution (...

Embodiment 2

[0049] 1. Clean the transparent glass substrate with a surface roughness of less than 1nm, and dry it in an incubator for more than 6 hours after cleaning;

[0050] 2. Coat a layer of detergent on the glass substrate, pour the PU on the glass substrate coated with detergent, vibrate slightly, spread the solution, and place it in a vacuum drying oven to dry (30°C, 12h), carefully peel off the flexible substrate from the glass substrate with a blade after drying;

[0051] 3. Spray the electrode of carbon paste (80-150nm) on the PU substrate;

[0052] 4. Clean the microscope slides with surface roughness less than 1nm, and dry them in an incubator for more than 6 hours after cleaning;

[0053] 5. Spin-coat the prepared PVA solution on a microscope slide (3000rpm, 60s), and dry the spin-coated slide (110°C, 2min) to obtain a PVA sacrificial layer;

[0054] 6. Under the condition of humidity of 88%RH, spin-coat the prepared P3HT mixed solution (P3HT:SEBS=2:1) onto the PVA sacri...

Embodiment 3

[0060] 1. Clean the transparent glass substrate with a surface roughness of less than 1nm, and dry it in an incubator for more than 6 hours after cleaning;

[0061] 2. Coat a layer of detergent on the glass substrate, pour the PU on the glass substrate coated with detergent, vibrate slightly, spread the solution, and place it in a vacuum drying oven to dry (30°C, 12h), carefully peel off the flexible substrate from the glass substrate with a blade after drying;

[0062] 3. Spray the electrode of carbon paste (80-150nm) on the PU substrate;

[0063] 4. Clean the microscope slides with surface roughness less than 1nm, and dry them in an incubator for more than 6 hours after cleaning;

[0064] 5. Spin-coat the prepared PVA solution on a microscope slide (3000rpm, 60s), and dry the spin-coated slide (110°C, 2min) to obtain a PVA sacrificial layer;

[0065] 6. Under the condition of humidity of 10%RH, spin-coat the prepared P3HT mixed solution (P3HT:SEBS=2:1) onto the PVA sacri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness range | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com