Carbon microspheres and preparation method thereof

A technology of carbon microspheres and biogas slurry, which is applied in the direction of carbon preparation/purification, waste fuel, etc., can solve the problems of difficult separation, complex process, and uneven particle size of carbon microspheres, and achieve simple process, uniform doping, and removal The effect of the resistance barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] A first aspect of the present invention protects a method for preparing carbon microspheres, comprising the following steps:

[0018] Step 1: The biomass raw material and biogas slurry are mixed according to a mass ratio of 1:5 to 20 to obtain a mixed solution.

[0019] Most of the raw materials for the preparation of existing carbon microspheres are sugars (glucose, starch, sucrose, etc.) and phenolic resins, and the cost is relatively high. The present invention uses natural biomass raw materials and biogas slurry as raw materials. The biogas slurry is obtained by anaerobic fermentation of kitchen waste. The cost of the two raw materials is very low, and the cost of the carbon microspheres obtained from these two raw materials is also very low. Low. The biogas slurry selected in the present invention is alkaline and contains nitrogen elements. The choice of alkaline biogas slurry is because the biomass raw material itself has the characteristics of compact structure...

Embodiment 1

[0043] Biogas slurry was obtained by fermenting kitchen waste with a concentration of 10g-VS / L and activated sludge with a concentration of 2g-VS / L at a temperature of 37°C and a pH of 6.5 for 20 days.

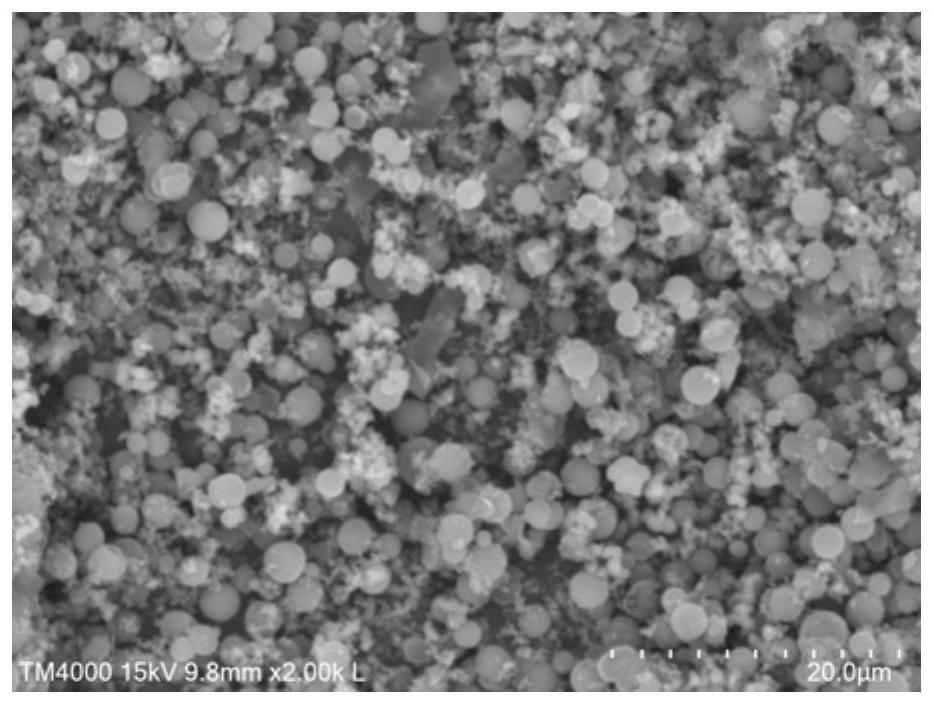

[0044] The corn stover was pulverized to a particle size of 1 mm. Then 10kg of corn stover powder was mixed with 100kg of biogas slurry to form a mixed solution. The mixed solution was put into the reaction kettle, and the reaction time was 6h under the conditions of a temperature of 260°C and a pressure of 6Mpa. After the reaction was completed, the reaction solution in the reaction kettle was discharged and allowed to stand for 24 hours. Take the supernatant and filter the supernatant for the first time using a 0.22um filter membrane. The solids filtered for the first time were rinsed with dichloromethane to remove oily organic matter on the surface, and then dried at 60° C. to obtain the first carbon microspheres. The filtrate filtered for the first time was allowed to s...

Embodiment 2

[0046] Biogas slurry was obtained by fermenting kitchen waste with a concentration of 8 g-VS / L and activated sludge with a concentration of 1.5 g-VS / L at a temperature of 35 °C and a pH of 7 for 25 days.

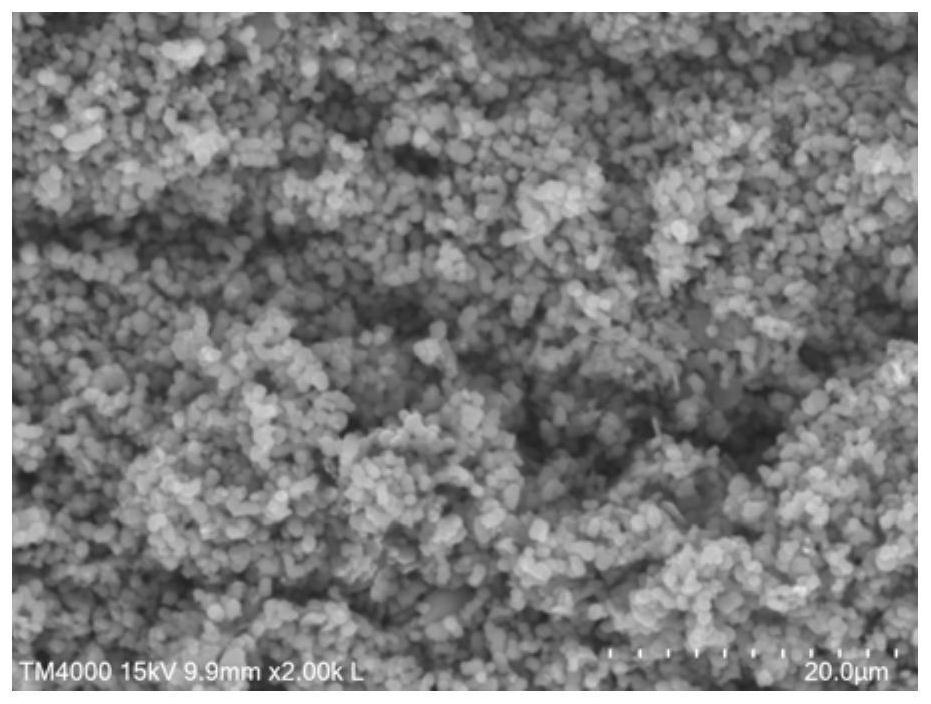

[0047] The corn stover was pulverized to a particle size of 0.8 mm. Then 15kg of corn stover powder was mixed with 100kg of biogas slurry to form a mixed liquor. The mixed solution was put into the reaction kettle, and the reaction time was 10h under the conditions of a temperature of 180°C and a pressure of 1.5Mpa. After the reaction was completed, the reaction solution in the reaction kettle was discharged and allowed to stand for 12 hours. Take the supernatant and filter the supernatant for the first time using a 0.4um filter membrane. The solids filtered for the first time were rinsed with dichloromethane to remove oily organic matter on the surface, and then dried at 50°C to obtain the first carbon microspheres. The filtrate of the first filtration was left to stand ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com