One-pot production process of methyl isopropyl ketone

A technology for the production of methyl isopropyl ketone, which is applied in the preparation of carbon-based compounds, the preparation of organic compounds, and organic chemistry, and can solve the problems of increasing sewage treatment costs, inability to carry out condensation reactions, and affecting product yields. Achieve the effects of reducing processing difficulty, improving cost advantages, and shortening reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

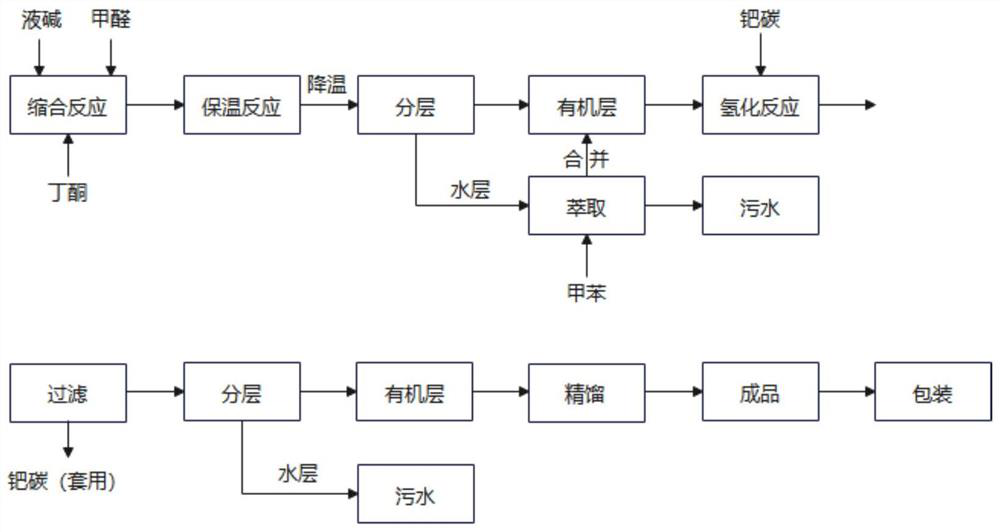

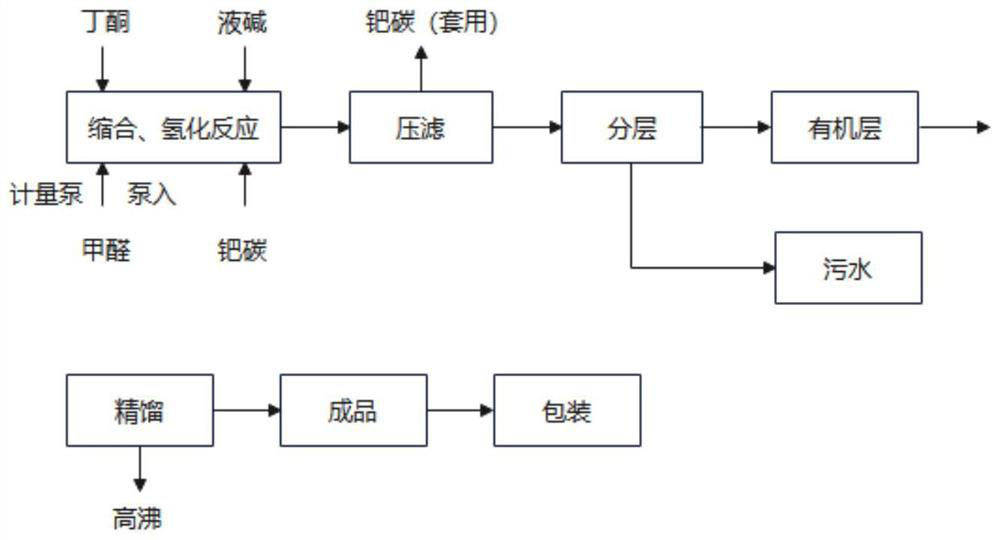

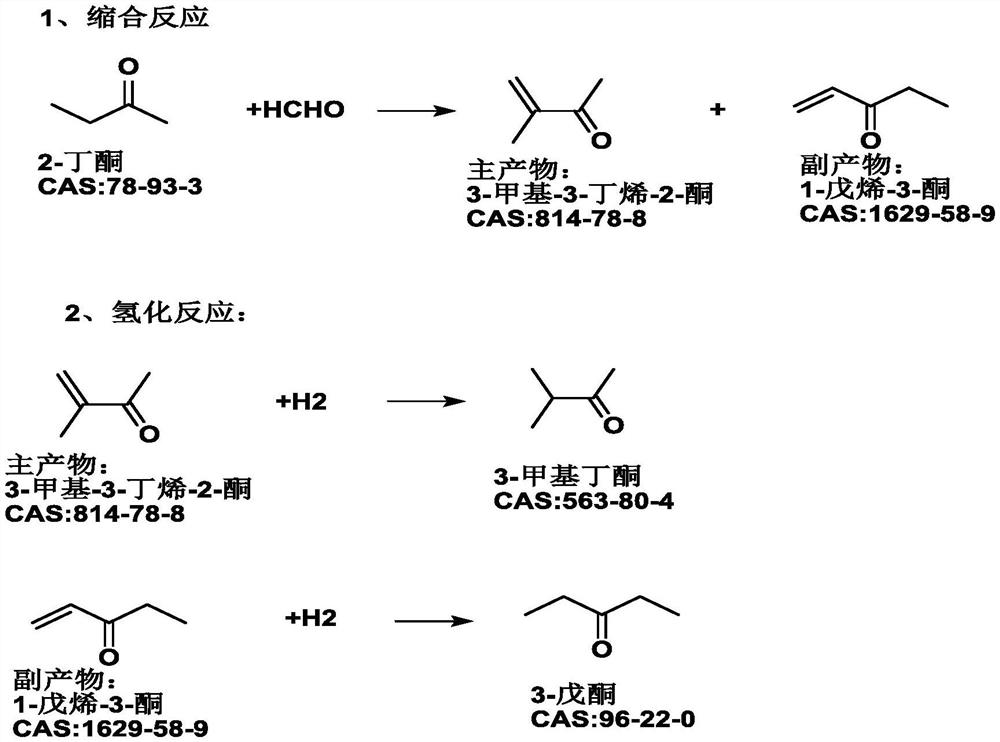

Method used

Image

Examples

Embodiment 1

[0032] Example 1 methyl isopropyl ketone one-pot cooking production process, the specific method is as follows:

[0033] (1) Add 1300kg of butanone, 15k g of palladium carbon and 30k g of alkaline catalyst to the hydrogenation reactor, and after replacing the nitrogen and hydrogen to the reactor without air residue, the pressure in the reactor is raised to 1MPa with hydrogen, and the material in the reactor is heated to 80 °C;

[0034] (2) Open the reactor stirring, pump the formaldehyde aqueous solution into the hydrogenation reactor at a flow rate of 50L / min, and control the reaction temperature of 80 °C and the reaction pressure of 1MPa;

[0035] (3) Control formaldehyde addition time is completed within 3 hours;

[0036] (4) After the end of the reaction, the material in the reactor is pressed out, and after layering, the organic layer is distilled, and the product is 1164k g of methyl isopropyl ketone, and the yield of methyl isopropyl ketone is 75% (measured in butanone), an...

Embodiment 2

[0037]Example 2 methyl isopropyl ketone one pot cooking production process, the specific method is as follows:

[0038] (1) Add 1300kg of butanone, 15kg of palladium carbon and 30kg of alkaline catalyst to the hydrogenation reactor, and after replacing the nitrogen and hydrogen to the reactor without air residue, the pressure in the reactor is raised to 1MPa with hydrogen, and the materials in the reactor are heated to 80 °C required for the reaction;

[0039] (2) Open the reactor stirring, the formaldehyde aqueous solution according to the flow rate of 30L / min through the high metering tank drops into the hydrogenation reactor, while controlling the reaction temperature of 80 °C, control the reaction pressure of 1MPa;

[0040] (3) Control formaldehyde addition time is completed within 4 hours;

[0041] (4) After the end of the reaction, the material in the reactor is pressed out, and after layering, the organic layer is distilled, and 1164kg of methyl isopropyl ketone is obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com