Preparation method and application of 6-aminocapronitrile catalyst prepared by caprolactam ammonification

An aminocapronitrile and caprolactam technology, which is applied in catalyst activation/preparation, carboxylic acid amide preparation, carboxylic acid amide dehydration preparation and other directions, can solve problems such as equipment blockage, and achieve the effects of low cost, improved catalyst strength and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

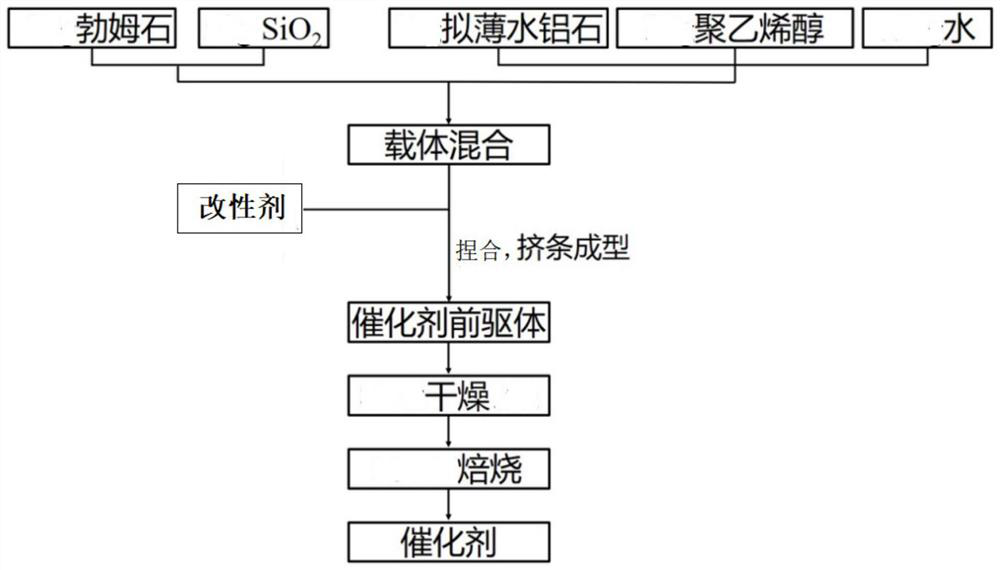

Method used

Image

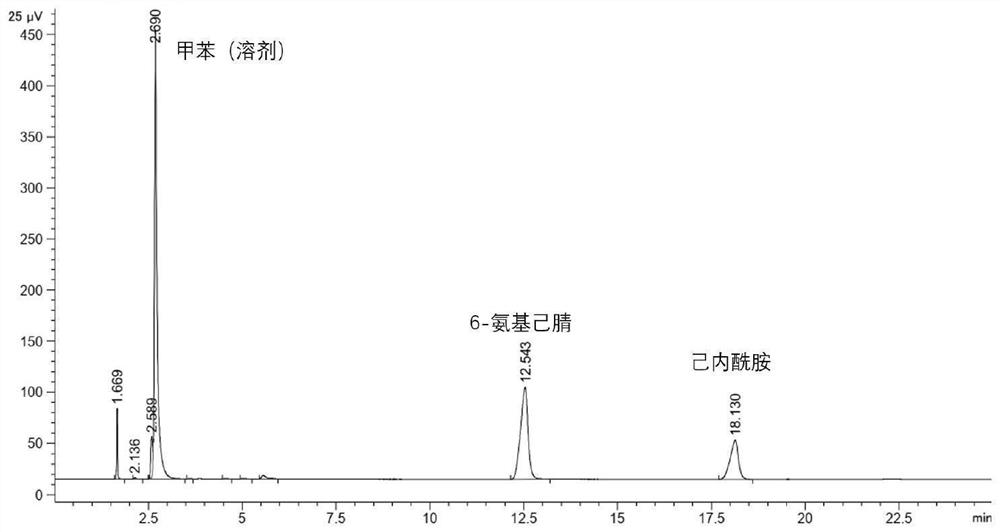

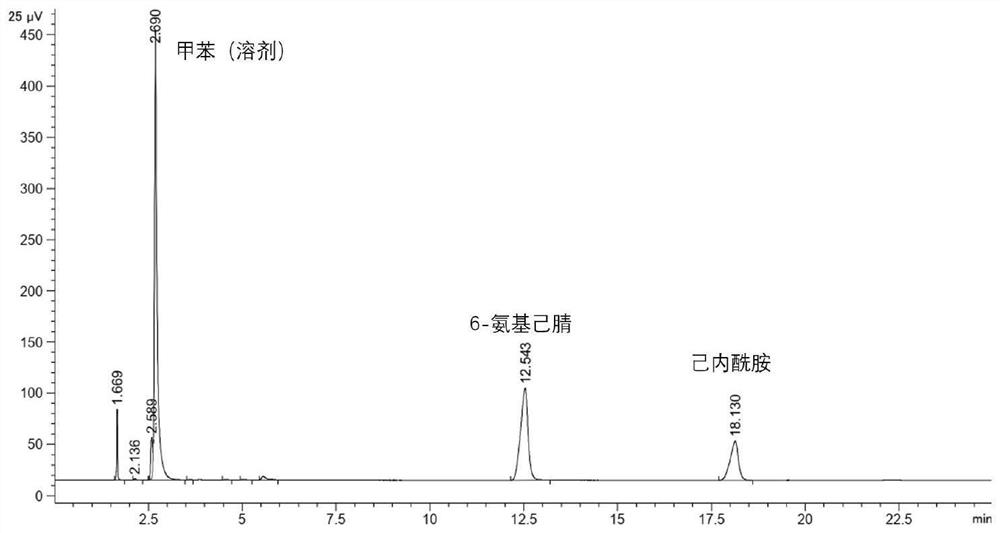

Examples

Embodiment 1

[0042]Put 150g of aluminum hydroxide powder into a round-bottomed flask with mechanical stirring, add 30g of pseudo-boehmite, 35g of succulent powder and 120g of water, after mixing evenly, add 14g of metaphosphoric acid and 10g of concentrated sulfuric acid and mix at 30°C for 2h , after 7 times of extrusion, drying at 40℃ for 20h; roasting the dried sample at 800℃ for 5h to obtain a 5×5mm cylindrical catalyst with a bulk density of 0.56g / ml.

Embodiment 2

[0044] Put 150g of γ-alumina powder into the kneader, add 15g of pseudoboehmite, 20g of polyvinyl alcohol and 120g of water, after mixing evenly, add 20g of phosphoric acid and 20g of oxalic acid and knead at 50 °C for 1 hour, and after 5 times of extrusion molding , dried at 80°C for 10h; calcined the dried sample at 850°C for 4h to obtain a 3×3mm cylindrical catalyst with a bulk density of 0.55g / ml.

Embodiment 3

[0046] Put 150g of sodium aluminate powder into the crusher, add 35g of pseudo-boehmite and 120g of water, mix well, add 15g of hypophosphorous acid and 15g of acetic acid, and knead for 1 hour at 30°C. Dry for 15h; roast the dried sample at 750℃ for 6h to obtain a 5×5mm cylindrical catalyst with a bulk density of 0.57g / ml.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com