Preparation method of MLCC nickel inner electrode slurry

A technology of inner electrode and slurry, which is applied in the direction of conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, fixed capacitor electrodes, etc., can solve the problem of not fully acting on ceramic powder, affecting the capacitance of MLCC, and insufficient dispersion effect Excellent and other problems, to achieve the effect of uniform long-term stability, small surface roughness, uniform dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

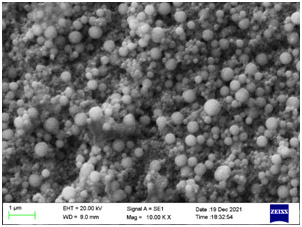

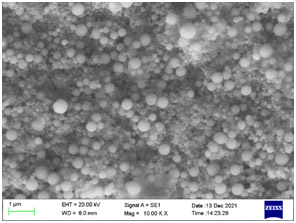

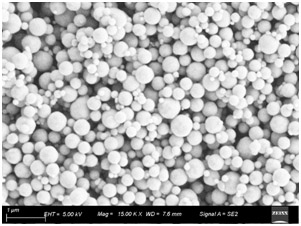

Image

Examples

Embodiment 1

[0029] A preparation method of MLCC nickel inner electrode slurry, the process steps are as follows:

[0030] (1) BaTiO with an average diameter of 100 nm 3 Powder, Aqueous Suspension Tween 80, Deionized Water, Hydroxyethyl Cellulose Blend, BaTiO 3 The mass ratio of powder, deionized water, and hydroxyethyl cellulose is 20:20:1. The water suspension agent Tween80 accounts for 0.5% of the mass of the ceramic powder. Stir for at least 10 minutes, and emulsifier at 3000 revolutions for 30 minutes until there are no large particles to obtain BaTiO. 3 an aqueous suspension;

[0031] (2) Mix octanol, terpineol, and ethyl cellulose according to a mass ratio of 18:72:10, and mechanically stir at 60°C for 5 hours to obtain an organic carrier;

[0032] (3) Combine the aqueous suspension prepared in step (1), the organic carrier prepared in step (2), Ni powder with an average diameter of 300 nm, terpineol, emulsifier sodium dodecyl sulfate (SDS), and phosphate dispersant. NP-4 is mixe...

Embodiment 2

[0035] A preparation method of MLCC nickel inner electrode slurry, the process steps are as follows:

[0036] (1) BaTiO with an average diameter of 100 nm 3 Powder, Aqueous Suspension Maleic Acid-Acrylic Acid Sodium Salt, Deionized Water, Hydroxyethyl Cellulose Mix, BaTiO 3 The mass ratio of powder, deionized water, and hydroxyethyl cellulose is 20:20:1, and the aqueous suspension agent maleic acid-sodium acrylic acid accounts for 1.5% of the mass of the ceramic powder. Stir for 15 minutes, and the emulsifier turns 3000 for 45 minutes. Large particles, resulting in BaTiO 3 an aqueous suspension;

[0037] (2) Mix octanol, terpineol, and ethyl cellulose according to a mass ratio of 18:72:10, and mechanically stir at 60°C for 5 hours to obtain an organic carrier;

[0038] (3) Mix the aqueous suspension prepared in step (1), the organic carrier prepared in step (2), Ni powder with an average diameter of 300 nm, terpineol, emulsifier monostearic fatty acid glyceride, and phospha...

Embodiment 3

[0041] A preparation method of MLCC nickel inner electrode slurry, the process steps are as follows:

[0042] (1) BaTiO with an average diameter of 100 nm 3 Powder, Aqueous Suspension Calcium Lignosulfonate, Deionized Water, Hydroxyethyl Cellulose Blend, BaTiO 3 The mass ratio of powder, deionized water and hydroxyethyl cellulose is 20:20:1, the water suspension agent calcium lignosulfonate accounts for 2.5% of the mass of the ceramic powder, stir for 15 minutes, and emulsifier at 3000 revolutions for 60 minutes until there are no large particles , to get BaTiO 3 an aqueous suspension;

[0043] (2) Mix octanol, terpineol, and ethyl cellulose according to a mass ratio of 18:72:10, and mechanically stir at 60°C for 5 hours to obtain an organic carrier;

[0044] (3) Disperse the aqueous suspension prepared in step (1), the organic carrier prepared in step (2), Ni powder with an average diameter of 300 nm, terpineol, emulsifier octylphenol polyoxyethylene ether (10), and phosphat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com