Assembled catalytic filler, preparation method thereof and application of assembled catalytic filler in flow chemical catalytic system

A technology of catalytic packing and body shape, which is applied in the field of catalysis, can solve the problems of easy aggregation of nanometer metals, degradation of catalytic performance, and decrease of effective surface area of catalysts, and achieve the effects of strong catalytic activity, convenient separation and recovery, and excellent catalytic reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

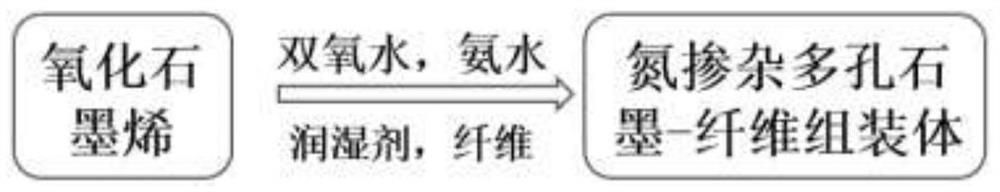

[0037] An assembly type catalytic filler, graphene oxide, wetting agent, aluminum silicate fiber, H 2 O 2 , NH 3 ·H 2 The mass ratio of O is 1:0.8:3.75:0.08:12.53; the specific preparation method includes the following steps:

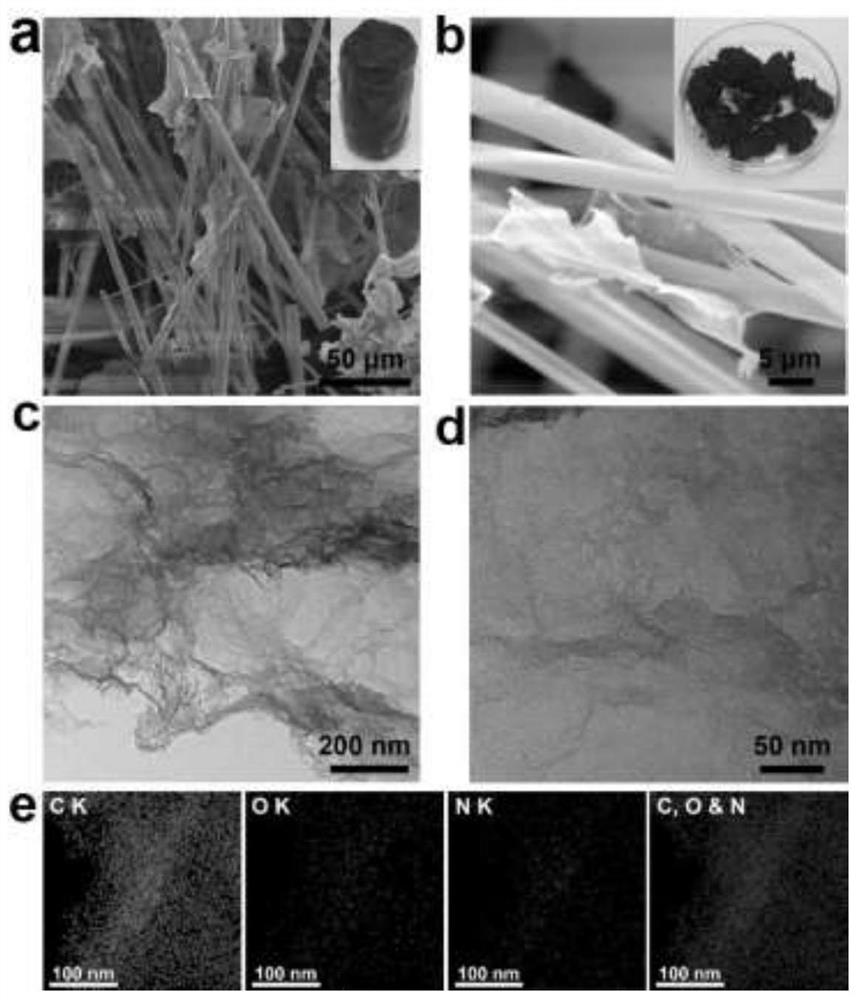

[0038] Take 46.37mL of graphene oxide dispersion with a concentration of 5.75mg / mL in a 100mL polytetrafluoroethylene reactor liner, add 1000mg of loose aluminum silicate fibers, 1mL of ethanol, and 7.2mL of 0.3wt% under stirring conditions. 14.0 mL of aqueous hydrogen peroxide solution and 14.0 mL of aqueous ammonia solution with a concentration of 28 wt%; after mixing uniformly, the inner tank was placed in a hydrothermal reaction kettle, and the hydrothermal reaction was carried out at 180 ° C for 8 h; after the reaction was completed, it was cooled to room temperature to obtain nitrogen-doped porous Graphene-aluminosilicate fibers (NHG-ASFs) assembly hydrogels.

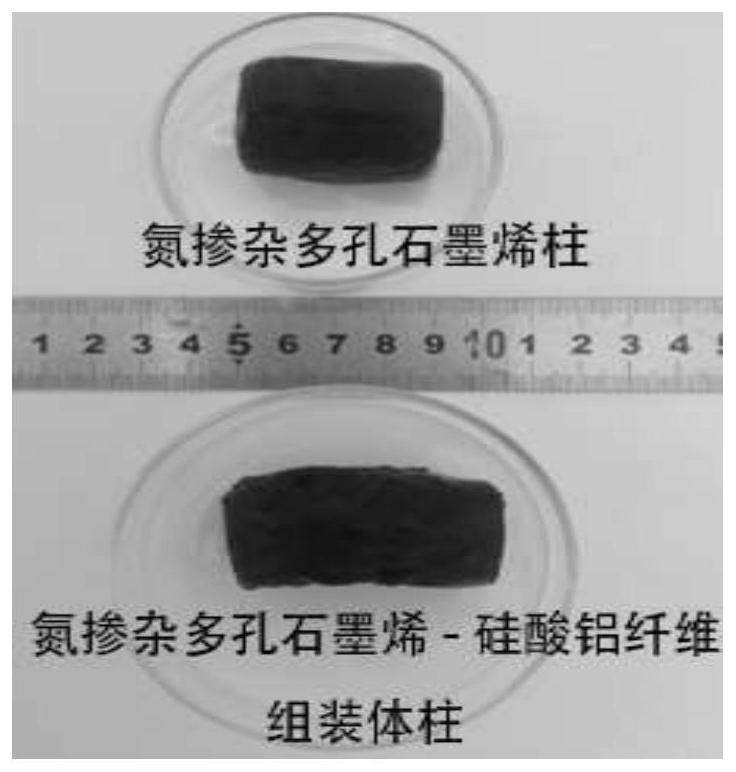

[0039] The nitrogen-doped porous graphene-aluminosilicate fiber assembly hydrogel o...

Embodiment 2

[0063] An assembly type catalytic filler, graphene oxide, wetting agent, aluminum silicate fiber, H 2 O 2 , NH 3 ·H 2 The mass ratio of O is 1:1.2:1.87:0.08:12.53; the specific preparation method includes the following steps:

[0064] Take 46.37mL of graphene oxide dispersion with a concentration of 5.75mg / mL in a 100mL polytetrafluoroethylene reactor liner, add 500mg of loose aluminum silicate fibers under stirring conditions, 1.5mL of acetone, 7.2mL of concentration is 0.3 wt% hydrogen peroxide solution and 14.0 mL ammonia solution with a concentration of 28wt%; after mixing uniformly, the inner tank was put into the hydrothermal reaction kettle, and the hydrothermal reaction was carried out at 180 ° C for 8h; after the reaction was completed, it was cooled to room temperature to obtain nitrogen-doped Heteroporous graphene-aluminosilicate fiber assembly hydrogels. The composite material can be used as a fixed bed catalyst with a flow rate of 13.3 ml / min and a conversion ...

Embodiment 3

[0066] An assembly type catalytic filler, graphene oxide, wetting agent, aluminum silicate fiber, H 2 O 2 , NH 3 ·H 2 The mass ratio of O is 1:0.8:2.8:0.08:12.53; the specific preparation method includes the following steps:

[0067] Take 46.37mL of graphene oxide dispersion liquid with a concentration of 5.75mg / mL in a 100mL polytetrafluoroethylene reactor liner, add 750mg of loose aluminum silicate fibers under stirring conditions, 1mL of ethanol, 7.2mL of concentration is 0.3wt % hydrogen peroxide solution and 14.0 mL of ammonia solution with a concentration of 28 wt%; after mixing uniformly, the inner tank was placed in a hydrothermal reaction kettle, and the hydrothermal reaction was carried out at 180 ° C for 8 h; after the reaction was completed, it was cooled to room temperature to obtain nitrogen doped Porous graphene-aluminosilicate fiber assembly hydrogel. The composite material can be used as a fixed bed catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com