Three-dimensional depth-of-field touch sensor and preparation method and application thereof

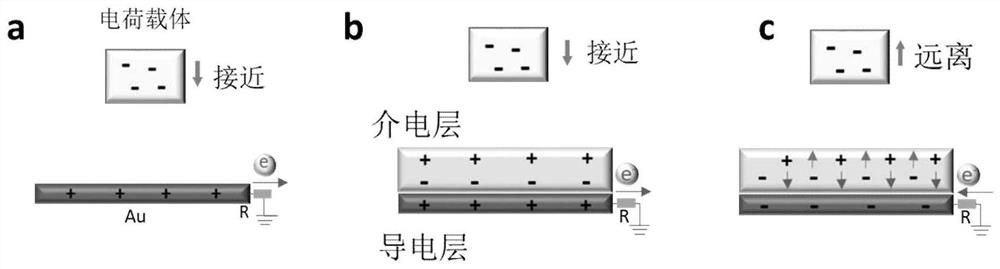

A tactile sensor, three-dimensional technology, applied in the direction of using electric/magnetic devices to transfer sensing components, vacuum evaporation plating, coating, etc., can solve the problems of complex device layout, high cost, incomplete external environment information transmission, etc., to achieve Effects of improving sensitivity, avoiding contact damage and power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The preparation process of the three-dimensional depth-of-field tactile sensor in this embodiment specifically includes the following steps:

[0050] (1) Preparation of nanoparticle-polymer composite thin film dielectric layer:

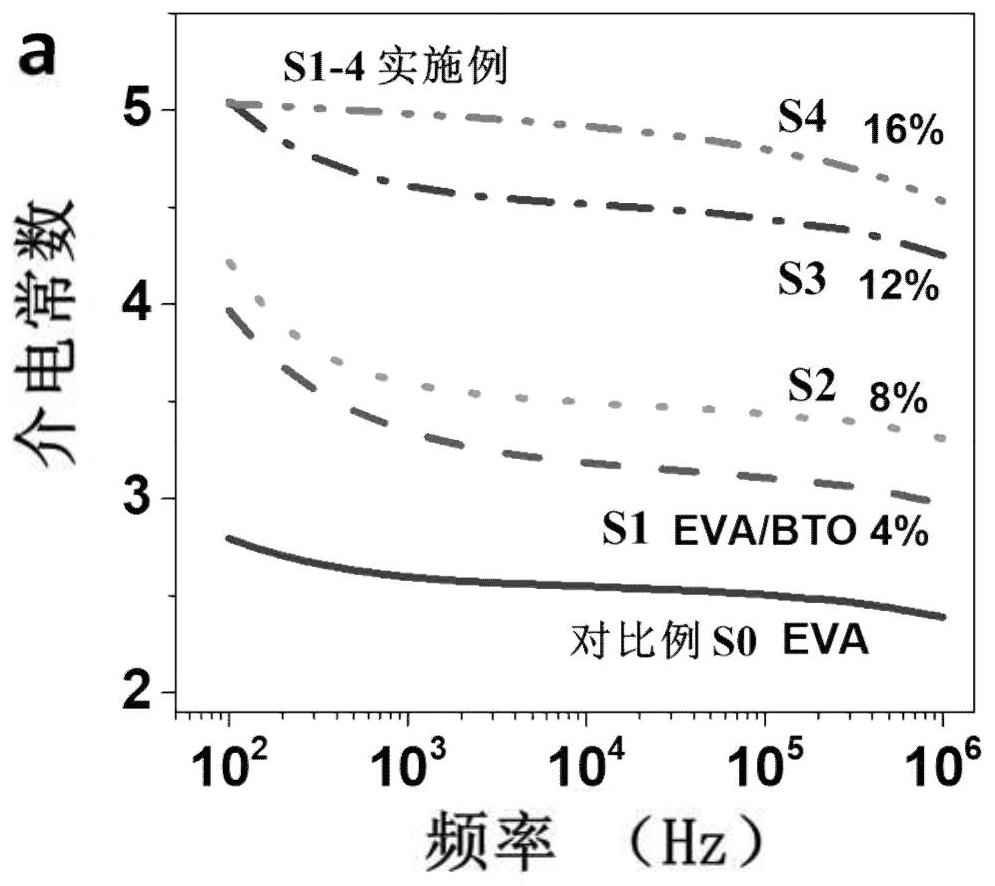

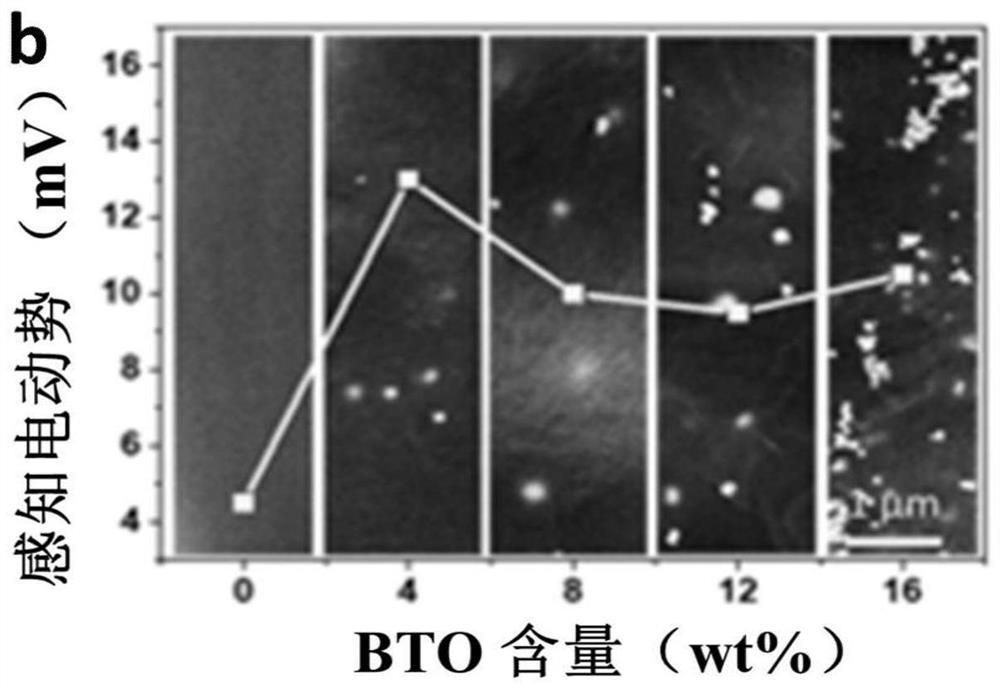

[0051] Take ethylene-vinyl acetate powder (EVA) and dichloromethane (CH 2 Cl 2 ) in a blue-necked bottle, magnetically stirring and dissolving at 80°C, stirring at a speed of 360 rpm, and stirring for 4 hours; after the ethylene-vinyl acetate powder is completely dissolved, add barium titanate nanoparticles (BTO), and sonicate for 1 hour at room temperature Then, pour the obtained mixed solution into an ultra-flat glass petri dish with a diameter of 60 mm, place it in a fume hood, and volatilize the solvent for 8 h to obtain a composite film with a thickness of about 130 μm;

[0052] (2) Preparation of conductive layer:

[0053] The composite film obtained in step (1) is cut into a circle with a diameter of 3 cm, and then a ring-shaped Au co...

Embodiment 2-4

[0055] The preparation process of the three-dimensional depth-of-field tactile sensor in this embodiment is the same as that of Embodiment 1, except that the amount of doped barium titanate nanoparticles is different. For details, see Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com