Short-chain alcohol intermediate for efficiently preparing high-molecular-weight polyether synthetic oil as well as preparation method and application of short-chain alcohol intermediate

A high-molecular-weight, short-chain alcohol technology, which is applied in the field of synthetic lubricating base oil preparation, can solve the problems of increased production cost, large yield loss, and many operating procedures, and achieves difficult deactivation, low production cost, and high reactivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Preparation of short-chain alcohol intermediates:

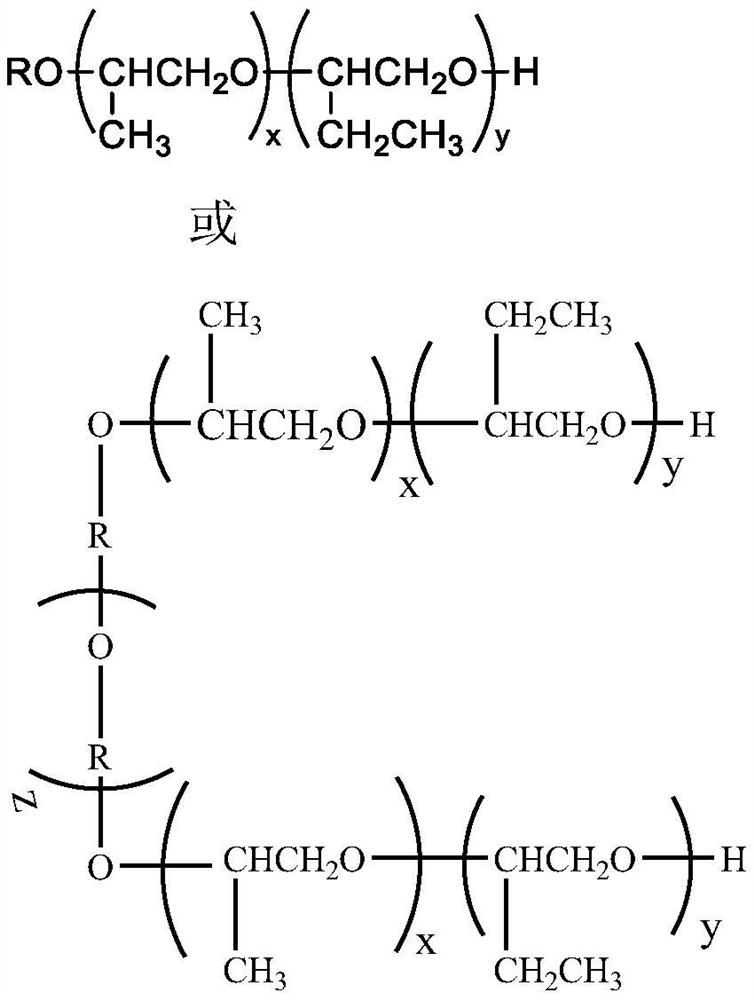

[0066] After mixing 150 g of the initiator dipropylene glycol and 1.12 g of the catalyst (boron trifluoride diethyl ether) and stirring evenly, vacuum and fill with N 2 Replace 5 times, heat up to 70 ℃, feed 25g of butylene oxide in 1min for induction, continue to add the remaining 373.9g of butylene oxide at a speed of 10g / min after the induction is completed, and control the reaction temperature at 85 ℃ and pressure at 50 psi, After adding butylene oxide, it was aged for 60 minutes, and then stripped in the kettle at 80 °C for 20 minutes to obtain a polyether synthetic oil intermediate with dipropylene glycol as the starting agent and a theoretical molecular weight of 490; the structural formula is as follows:

[0067]

[0068] where the y value is 2.5.

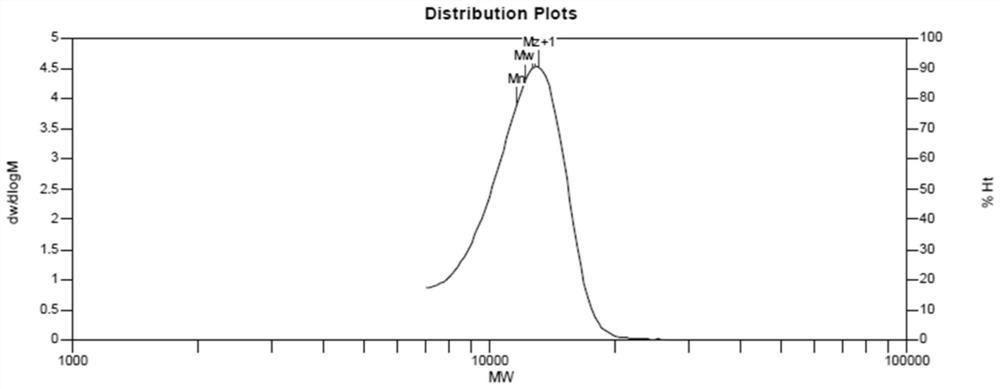

[0069] According to GPC analysis, the molecular weight distribution of the short-chain alcohol intermediate prepared in this example is PD=1.14.

Embodiment 2

[0071] Preparation of short-chain alcohol intermediates:

[0072] Mix 101.3 g of the initiator 1,2 propylene glycol and 1.60 g of catalyst (boron trifluoride diethyl ether) and stir evenly, vacuum and fill with N 2 Replace 5 times, heat up to 70 ℃, feed 25g of butylene oxide within 1min for induction, continue to add the remaining 406.4g of butylene oxide at a speed of 20g / min after the induction is completed, and control the reaction temperature at 80 ℃ and pressure at 45 psi, After adding butylene oxide, it was aged for 60 minutes, and then stripped in the kettle at 80 °C for 20 minutes to obtain a polyether synthetic oil intermediate with 1,2-propanediol as the starting agent and a theoretical molecular weight of 400; the structural formula is as follows:

[0073]

[0074] Where: y value is 2.25.

[0075] According to GPC analysis, the molecular weight distribution of the short-chain alcohol intermediate prepared in this example is PD=1.10.

Embodiment 3

[0077] Preparation of short-chain alcohol intermediates:

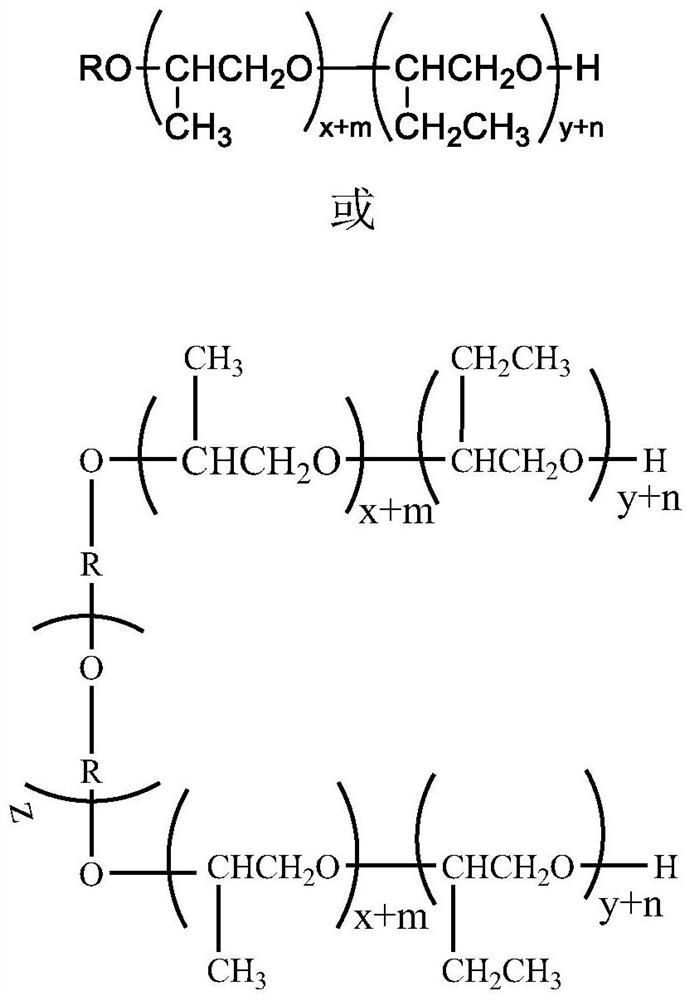

[0078] After mixing 115 g of n-butanol and 1.40 g of catalyst (titanium tetrachloride), the starting agent, and stirring evenly, vacuum was filled with N 2 Replace 5 times, heat up to 70°C, introduce 22g of propylene oxide for induction within 1 min, continue to add the remaining 158g of propylene oxide and 403.2g of butylene oxide at a rate of 15g / min after the induction is completed, and control the reaction temperature to 70°C , pressure 35psi, after adding butylene oxide, aging for 60min, and then stripping in the kettle at 80 ℃ for 20min to obtain a polyether synthetic oil intermediate with n-butanol as a starting agent and a theoretical molecular weight of 450; the structural formula is as follows:

[0079]

[0080] where the x value is 3.1 and the y value is 5.6.

[0081] Molecular weight distribution PD=1.08 by GPC analysis.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com