Boron-containing polymer pour point depressant for biodiesel-petrochemical diesel blended oil as well as preparation method and application of boron-containing polymer pour point depressant

A petrochemical diesel and biodiesel technology, applied in biofuels, petroleum industry, fuel additives, etc., can solve the problems affecting the storage, transportation and use of oil products in cold regions, the loss of low-temperature fluidity of biodiesel, and the clogging of fuel pipelines or filters To achieve the effect of enhancing pour point depressing effect, improving low temperature flow performance and improving cloud point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] In order to achieve the above purpose, the present invention provides a boron-containing polymer pour point depressant for biodiesel-petrochemical diesel blended oil and its preparation method and application, comprising the following steps:

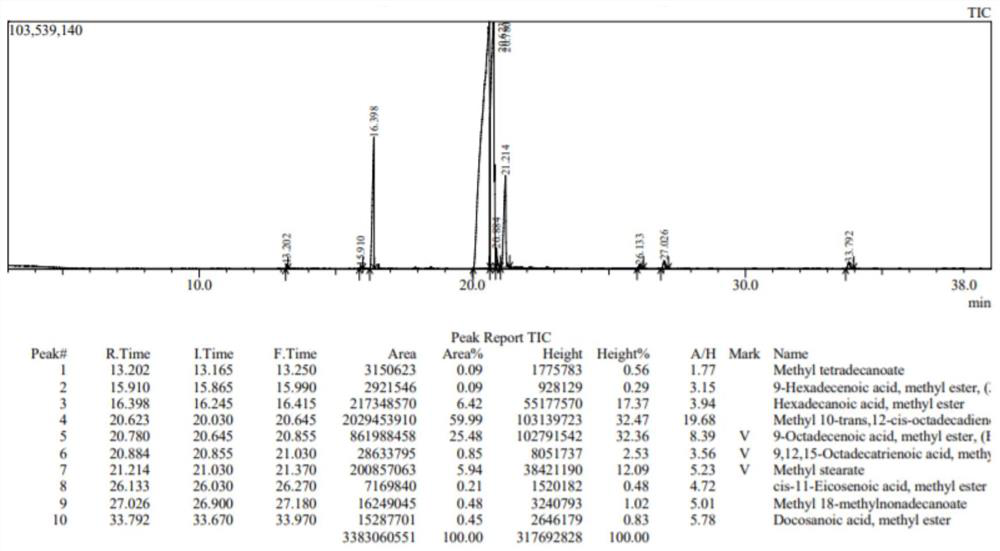

[0036] Step 1: Synthesis of tetradecyl methacrylate: mix tetradecanol and methacrylic acid in proportion, add solvent, catalyst and polymerization inhibitor, heat and react, the product is washed with alkali, washed with water, rotary evaporated and dried in vacuum to obtain methyl methacrylate. The ratio of tetradecyl acrylate; tetradecanol to methacrylic acid is (1.1-1.3):1, most preferably 1.2:1. The solvent is toluene, and its amount is 20-40ml, most preferably 30ml. The polymerization inhibitor is hydroquinone, and its dosage is 0.50-0.70% of the total mass of methacrylic acid and tetradecanol, most preferably 0.6%. The catalyst is p-toluenesulfonic acid, and the amount thereof is 1.1-1.3% of the total mass of methacrylic ac...

Embodiment 1

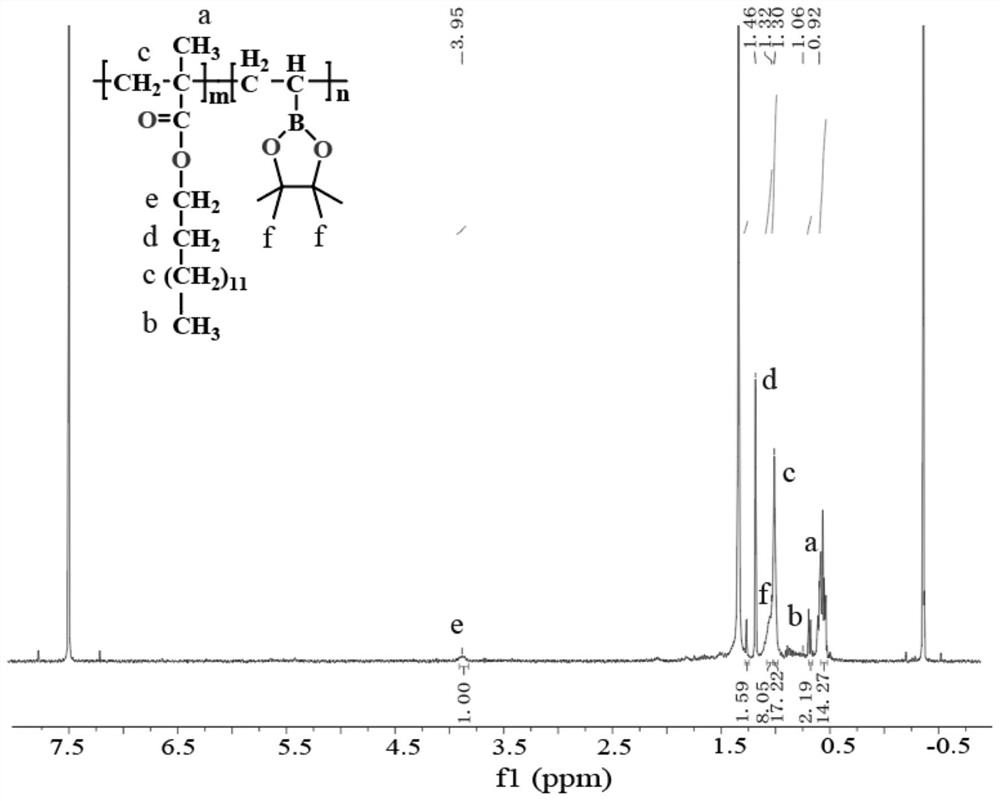

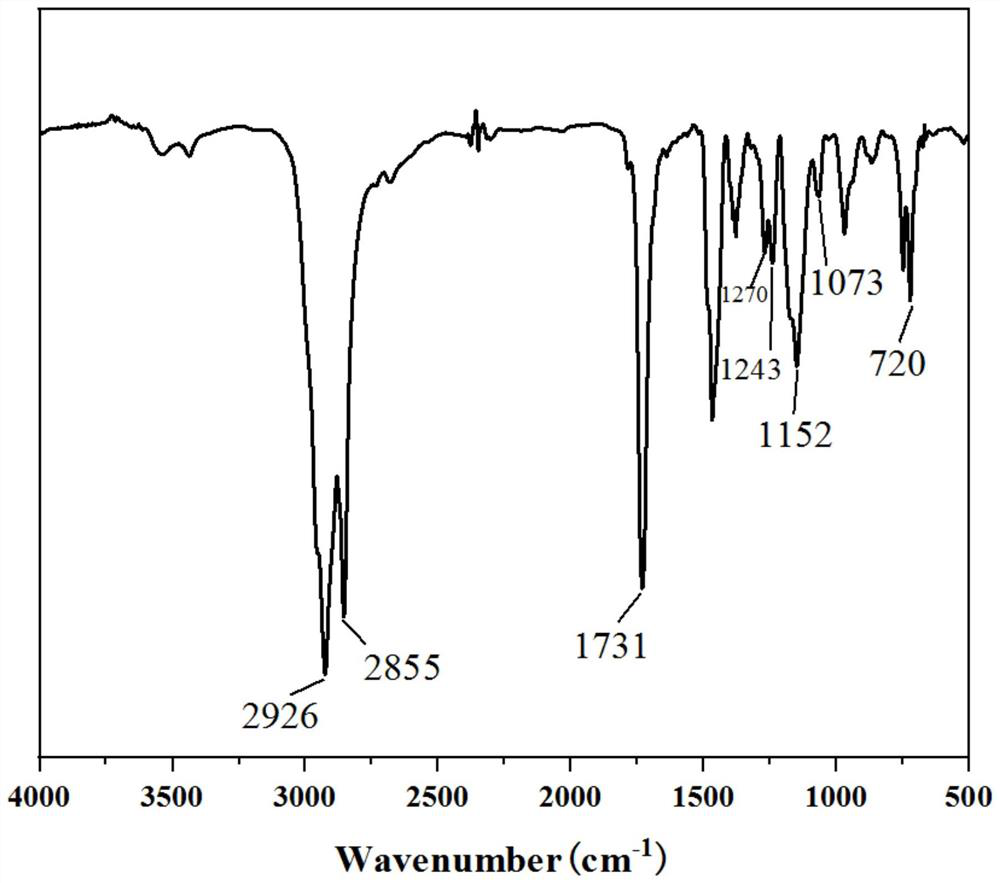

[0048] A pour point depressant that can reduce the cloud point, cold filter point and condensation point of soybean oil biodiesel-petrochemical diesel blended oil, is a polymerization product of tetradecyl methacrylate and pinacol allyl borate. material, its preparation method is:

[0049] The three-necked flask was equipped with a constant pressure separatory funnel, a reflux condenser, and a nitrogen introduction tube, placed in a constant temperature magnetic stirrer, and 4.237g (0.015mol) of tetradecyl methacrylate, 0.840g (0.005mol) of allyl were added in turn base boric acid pinacol ester and 20 ml of toluene solvent, the three-necked flask was evacuated for 3 min, passed nitrogen for 3 min, and the vacuum and nitrogen were repeated three times each to completely remove the air in the reaction flask. When the temperature reached 120°C, 10 mL of a toluene solution dissolved in 0.051 g of benzoyl peroxide was slowly added dropwise (dropping was completed in 30-45 minutes),...

Embodiment 2

[0052] A pour point depressant that can reduce the cloud point, cold filter point and condensation point of soybean oil biodiesel-petrochemical diesel blended oil, is a polymerization product of tetradecyl methacrylate and pinacol allyl borate. material, its preparation method is:

[0053] The three-necked flask was equipped with a constant-pressure separatory funnel, a reflux condenser, and a nitrogen inlet tube, placed in a constant-temperature magnetic stirrer, and 4.237g (0.015mol) of tetradecyl methacrylate, 0.420g (0.0025mol) of alkene were sequentially added. Propylboronic acid pinacol ester and 20 ml of toluene solvent, the three-necked flask was evacuated for 3 min, passed nitrogen for 3 min, and the vacuum and nitrogen were repeated three times each to completely remove the air in the reaction flask. When the temperature reached 120°C, 10 mL of a toluene solution dissolved in 0.047g of benzoyl peroxide was slowly added dropwise (dropping was completed in 30-45 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com