Preparation method and application of nanocrystalline tungsten bronze

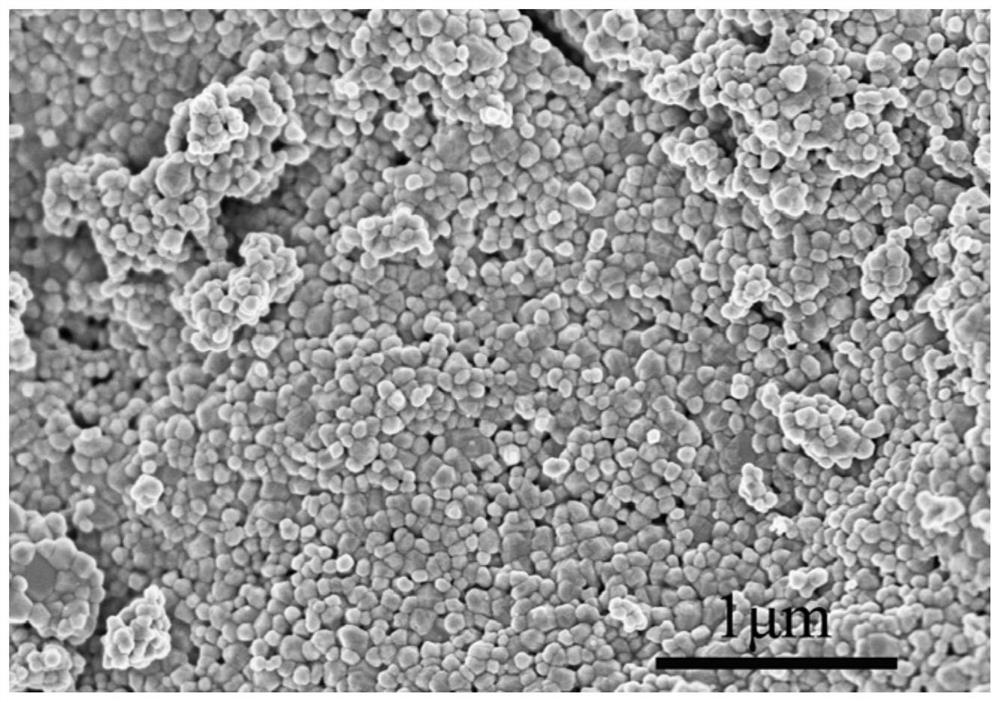

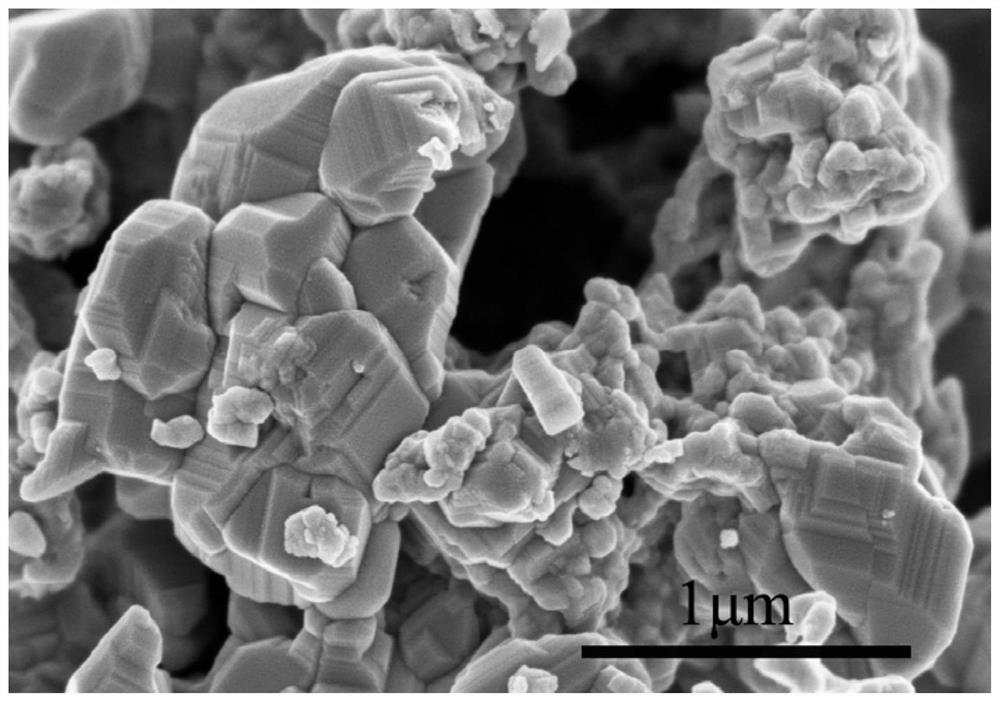

A technology of tungsten bronze and nanocrystals, which is applied in the field of preparation of tungsten bronze nanomaterials, can solve the problems of large particle size and unstable transparent heat insulation performance, and achieve the effects of small particles, good transparent heat insulation stability, and environmentally friendly prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of nanocrystalline tungsten bronze provided by one aspect of the present invention comprises the following steps:

[0032] S1. Dissolve one or more of alkali metal compounds, alkaline earth metal compounds, rare earth compounds and tungstate in water, stir and mix;

[0033] S2, the mixture obtained in step S1 is placed in a drying oven to dry, and then ground to obtain a solid product;

[0034] S3, placing the solid product obtained in step S2 in a high-temperature furnace, feeding nitrogen-hydrogen mixed gas, and reacting at 400-1200 ° C for 10-1200 min;

[0035] S4. The solid product obtained after the reaction in step S3 is placed in an inert protective atmosphere to continue the reaction to obtain nanocrystalline tungsten bronze.

[0036] Specifically, in step S1, the chemical formula of the tungsten bronze is M x WO 3 , wherein 0<x<1, M is at least one of alkali metals, alkaline earth metals or rare earth elements.

[0037] Specifically, ...

Embodiment 1

[0048] The preparation method of nanocrystalline lanthanum tungsten bronze provided by the present invention comprises the following steps:

[0049]S1. Take 0.0858g of lanthanum chloride and 0.6375g of ammonium tungstate, put these two medicines into 100ml of deionized water, stir in a magnetic stirrer for 1 hour, and stir evenly;

[0050] S2, put the obtained mixture into a constant temperature drying oven, dry at 180°C for 8h, take out the powder and grind for 30min;

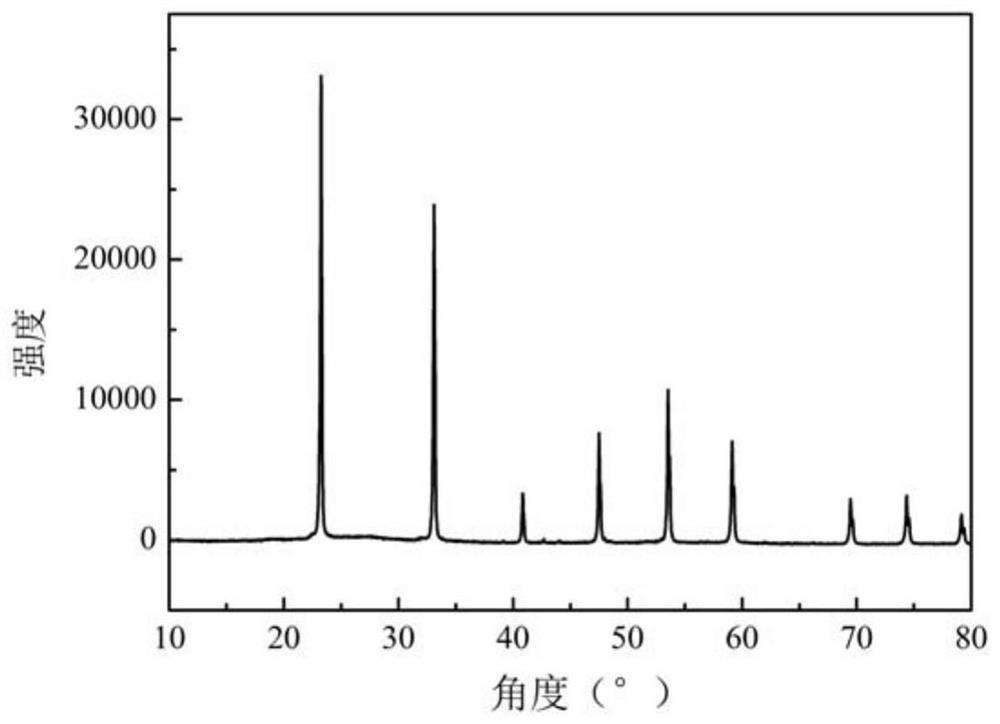

[0051] S3. Put the powder into a tube furnace, heat up to 500°C, and at the same time fill with nitrogen-hydrogen mixture (95 / 5) for reduction for 1h; then heat up to 800°C, introduce nitrogen, and keep for 1h to obtain nanocrystalline lanthanum tungsten bronze.

Embodiment 2

[0064] The nanocrystalline lanthanum tungsten bronze prepared in Example 1 was made into a thermal insulation coating glass, and the thermal insulation effect of the lanthanum tungsten bronze coating glass was tested.

[0065] The production method of lanthanum tungsten bronze coated glass:

[0066] S1. Dissolve 0.2 g of the nanocrystalline lanthanum tungsten bronze prepared in Example 1 in 20 ml of ethanol solution, ultrasonically disperse for 30 min, then add 5 g of PVB resin under strong magnetic stirring, and stir for 20 min to obtain a coating slurry.

[0067] S2. Place a glass sheet on the spin coater, rotate at a speed of 2000r / min, drop the prepared coating slurry on the glass sheet and rotate for 40s to obtain the coated glass, and finally keep the coated glass at 40°C for 1 hour to Remove residual liquid.

[0068] Test method for the performance of lanthanum tungsten bronze coated glass: place the prepared lanthanum tungsten bronze coated glass and blank glass on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com