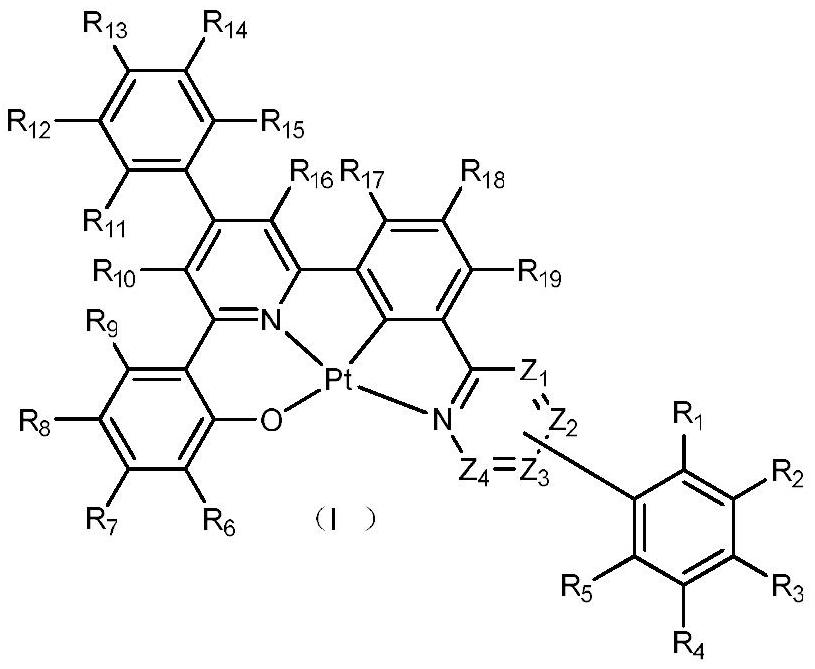

Tetradentate ONCN platinum complex containing multi-nitrogen heterocyclic ring

A platinum complex, nitrogen heterocycle technology, applied in the field of OLED materials, can solve the problems of difficult molecular purification of divalent platinum complexes, easy to be attacked by halogen, unfavorable materials, etc., to enhance electron cloud density, increase steric hindrance, improve The effect of binding capacity

- Summary

- Abstract

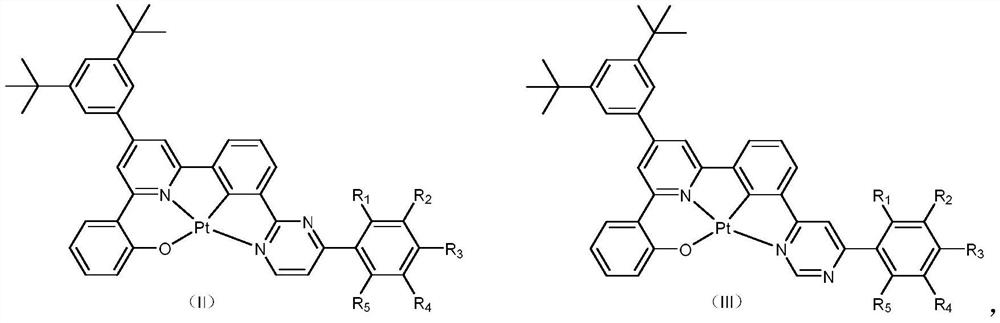

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

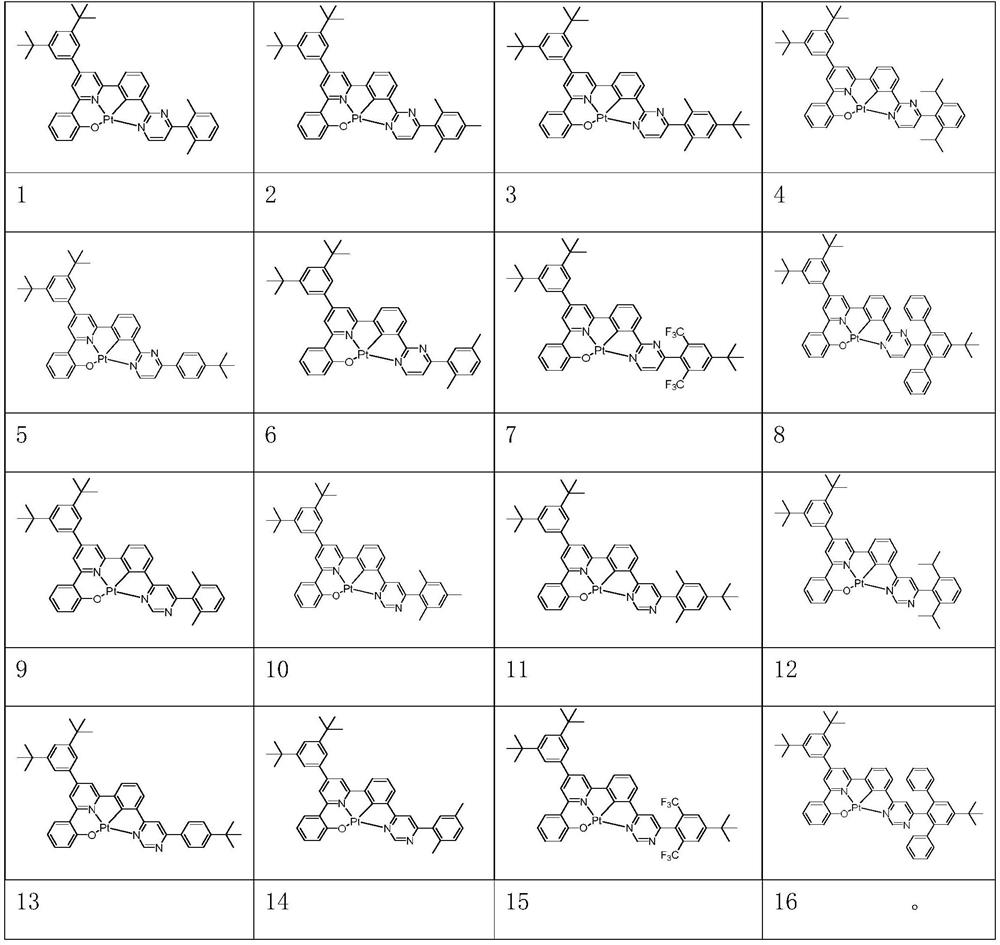

Examples

Embodiment 1

[0032] Example 1: Synthesis of complex 3

[0033]

[0034] Synthesis of intermediate B: In a 250ml three-necked flask, add compound A (12g, 50mmol), dissolve in 100ml of anhydrous tetrahydrofuran, install a constant pressure dropping funnel, evacuate nitrogen three times, and stir at -78°C for 30 minutes. Take n-butyllithium (29.9ml, 2.5M) into a constant pressure dropping funnel, slowly drop it into the reaction solution, and stir at the same temperature for 30 minutes after all drops are completed. Take isopropanol pinacol borate (13.9g, 75mmol) into the reaction solution, then move the whole reactor to normal temperature and stir for 1 hour, after the reaction is finished, the water layer is separated and filtered off, and the organic phase is filtered through anhydrous sulfuric acid. After sodium drying, rotary evaporation was performed to obtain 10.5 g of white powder B with a yield of 72.83%.

[0035] Synthesis of intermediate D: in a 250ml single-necked flask, add i...

Embodiment 2

[0041] Example 2: Synthesis of complex 11

[0042]

[0043] Synthesis of intermediate J: in a 250ml single-necked flask, add intermediate E (10.0g, 17.27mmol), compound I (7.6g, 51.80mmol), tetrakistriphenylphosphine palladium (0.50g, 0.86mmol), anhydrous Potassium phosphate (11.4g, 43.17mmol), 160ml of toluene / ethanol / water=5 / 2 / 1 mixed solution was used as the reaction solvent, stirred in an oil bath at 50°C under nitrogen protection for 16 hours, after the reaction was completed, 100ml of water and 50ml of After extraction with ethyl acetate three times, the organic phase was dried over anhydrous sodium sulfate and then chromatographed on silica gel column (the chromatographic solution was n-hexane:ethyl acetate=10:1). The crude product obtained was concentrated, stirred and crystallized with 50 ml of methanol to obtain 8.40 g of white Solid J, yield 86.70%. Hydrogen nuclear magnetic spectrum: 1H NMR (400MHz, CDCl3) δ9.06 (d, J=0.8Hz, 1H), 8.82 (s, 1H), 8.31 (d, J=7.8Hz,...

Embodiment 3

[0051] Under a nitrogen atmosphere, weigh about 5.0 mg of fully dried samples of platinum complexes 3 and 11 respectively, set the heating scanning speed to 10 °C / min, the scanning range is 25-800 °C, and the measured thermal decomposition temperatures are 383.74 °C, 419.71°C (the temperature corresponding to 0.5% thermal weight loss), indicating that this type of complex has very good thermal stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com