Phase change heat storage composite material with flame retardance and flexibility as well as preparation method and application of phase change heat storage composite material

A technology of phase change heat storage and composite materials, which is applied in the field of phase change heat storage materials, can solve problems such as difficulty in meeting practical application requirements, failure to consider electrical insulation, lack of flexibility, etc., to achieve large-scale industrial application and good safety Protective effect, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

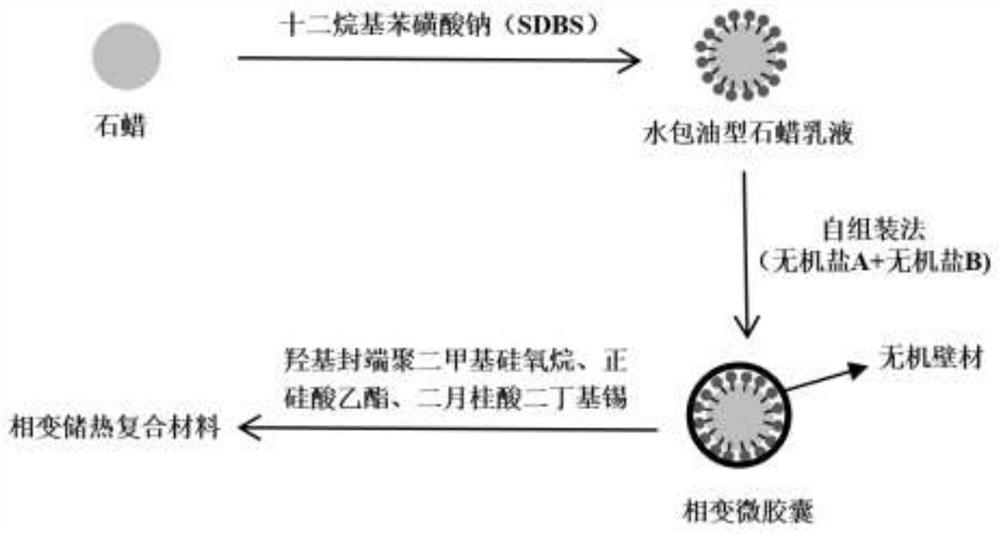

[0039] The flow chart of the preparation of phase change heat storage composites is as follows: figure 1 As shown, the specific preparation steps are as follows:

[0040] S1, the preparation of phase change microcapsules:

[0041]The paraffin wax was heated to 60°C to melt to a transparent liquid state, an aqueous solution of sodium dodecylbenzenesulfonate (mass fraction 1.4%) was added, and after mechanical stirring for 20 minutes, an oil-in-water paraffin wax emulsion was obtained. The aqueous solution of inorganic salt A (7% by mass) and the aqueous solution of inorganic salt B (8.5% by mass) were slowly added dropwise to the paraffin wax emulsion, respectively, and stirred for 3 hours. The reaction product is subjected to suction filtration and washing in sequence, and dried at 30 to 40° C. for 24 to 36 hours to obtain white powdery phase-change microcapsules.

[0042] S2. Preparation of flexible composite materials:

[0043] After the hydroxyl terminated polydimethylsi...

Embodiment 1

[0048] 20g of paraffin was placed in a 500ml three-necked flask, heated to 60°C and melted to a transparent liquid state, 50g of an aqueous solution of sodium dodecylbenzenesulfonate (mass fraction was 1.4%) was added, and after mechanical stirring for 20 minutes, a water-in-water solution was obtained. Oil-based paraffin emulsion. The aqueous solution of 80 grams of calcium chloride (mass fraction is 7%) and the aqueous solution of 80 grams of potassium carbonate (mass fraction of 8.5%) were slowly added dropwise to the paraffin emulsion, respectively, mechanically stirred for 3 hours (stirring speed was 300 rpm) / minute). The reaction product was subjected to suction filtration, washed twice with distilled water and petroleum ether in turn, and dried at 40° C. for 36 hours to obtain white powdery phase-change microcapsules. After mixing 52 grams of hydroxyl-terminated polydimethylsiloxane, 2.6 grams of ethyl orthosilicate, and 1.0 grams of dibutyltin dilaurate, 40 grams of ...

Embodiment 2

[0051] 20g of paraffin was placed in a 500ml three-necked flask, heated to 60°C and melted to a transparent liquid state, 50g of an aqueous solution of sodium dodecylbenzenesulfonate (mass fraction was 1.4%) was added, and after mechanical stirring for 20 minutes, a water-in-water solution was obtained. Oil-based paraffin emulsion. The aqueous solution of 80 grams of calcium chloride (mass fraction is 7%) and the aqueous solution of 80 grams of potassium carbonate (mass fraction of 8.5%) were slowly added dropwise to the paraffin emulsion, respectively, mechanically stirred for 3 hours (stirring speed was 300 rpm) / minute). The reaction product was suction filtered, washed twice with distilled water and petroleum ether in turn, and dried at 30° C. for 24 hours to obtain white powdery phase-change microcapsules. After mixing 42 grams of hydroxyl terminated polydimethylsiloxane, 2.1 grams of ethyl orthosilicate, and 0.8 grams of dibutyltin dilaurate, 50 grams of phase change mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com