High-performance processable hydrogel as well as preparation method and application thereof

A polymer hydrogel and hydrogel technology, applied in the field of polymer chemical materials, can solve problems such as poor fit, limited application, and gap in mechanical properties, and achieve the effect of promoting mineralization and high application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Example 1. Preparation of Sodium Alginate Hydroxyapatite Particle Hybrid Polyvinyl Alcohol Hydrogel

[0054] The polyvinyl alcohol PBS solution was mixed with hydroxyapatite particles with a particle size of 10 nm to obtain a polyvinyl alcohol PBS mixed solution with a mass percentage of 1% of the bioceramic material particles, and sodium 4-carboxyphenyl borate was added to sodium alginate (average The relative molecular weight is 150 kDa) and mixed evenly in the PBS solution to obtain a PBS mixed solution with an alginate mass percentage of 60%. After mixing the above two solutions uniformly, a cylindrical hydrogel sample was obtained by hand molding. The mass percentages of alginate, bioceramic material particles, 4-carboxyphenylboronic acid and polyvinyl alcohol in the obtained final target hydrogel are 50%, 0.5%, 3% and 7%, respectively.

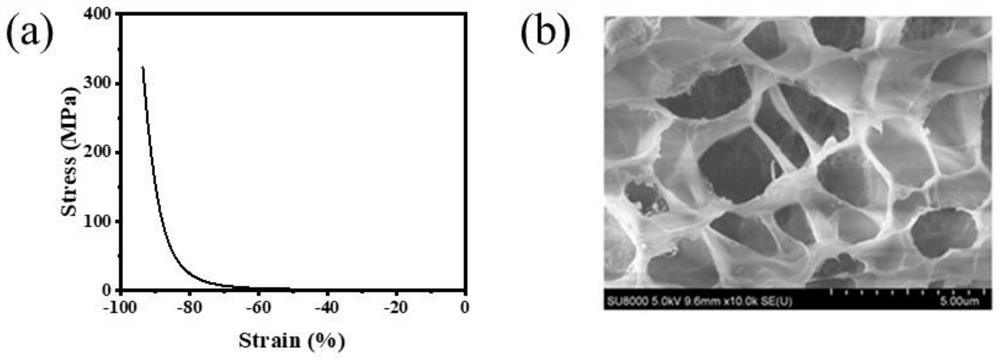

[0055] Test the compression curve of the hydrogel sample obtained in this example, and the results are as follows figure 1 sho...

Embodiment 2

[0057] Example 2. Preparation of Potassium Alginate-Bioactive Glass Particles and Silica Particles Hybrid Dextran Hydrogel

[0058] The mixture obtained by mixing bioactive glass particles with a particle size of 100 μm and silica particles with a particle size of 100 μm according to a mass ratio of 1:1 was added to the dextran aqueous solution to obtain a dextran with a mass percentage of 10% of the bioceramic material particles. mixed aqueous solution;

[0059] Mixing potassium alginate (average relative molecular mass is 5kDa) with epichlorohydrin to obtain a homogeneous aqueous solution with a mass percentage of alginate of 50%;

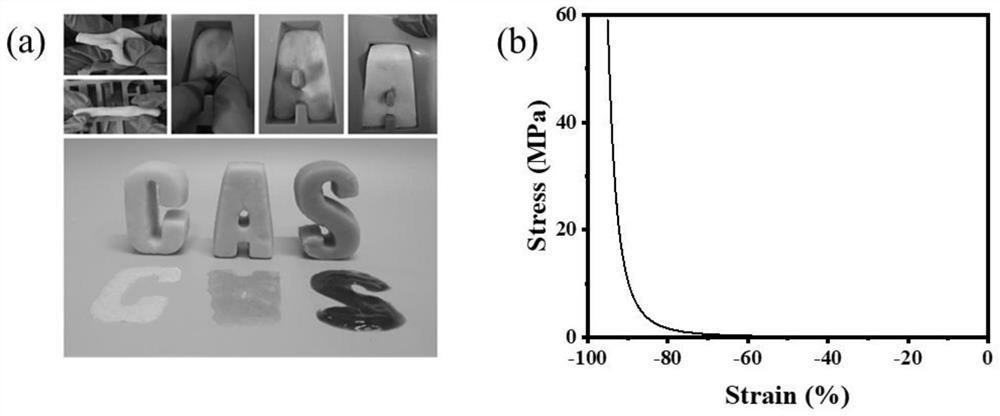

[0060] After mixing the above two solutions, follow the figure 2In the hand molding process shown in (a), hydrogel samples with different letter shapes are obtained by hand molding; wherein, the obtained final target hydrogel contains potassium alginate, bioceramic material particles, dextran, epoxy The mass percentages of chloropropane are 40...

Embodiment 3

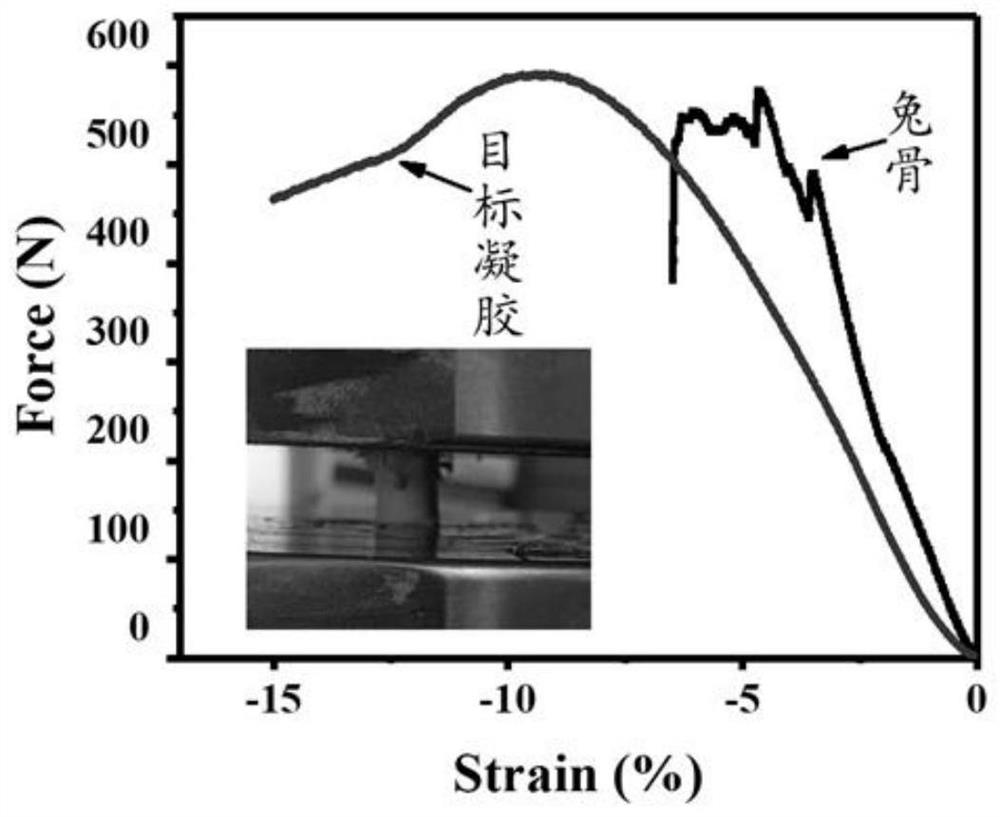

[0062] Example 3. Calcium alginate, ammonium alginate-silica particles and calcium carbonate bone cement particles and calcium sulfate particles and calcium carbonate particles Hybrid polyethylene glycol-polylactic acid copolymer, polyglycolide / lactide Preparation of Ester Copolymer and Polyglycolactone Copolymer Hydrogel

[0063] Silica particles with a particle size of 100 nm, calcium carbonate bone cement particles with a particle size of 80 nm, calcium sulfate particles with a particle size of 10 μm, and calcium carbonate particles with a particle size of 20 nm were added to polyethylene in a mass ratio of 1:2:1:2. The mixed aqueous solution of glycol-polylactic acid copolymer, polyglycolide / lactide copolymer and polyglycolactone copolymer is stirred evenly to obtain a mixed aqueous solution with a mass percentage of bioceramic material particles of 15%. Calcium alginate and ammonium alginate are made into an aqueous solution with an alginate mass percentage of 30% accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compression modulus | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com