Composite nano material as well as preparation method and application thereof

A composite nanomaterial and nanosheet technology, applied in the field of materials, can solve the problems of poor product uniformity, poor treatment effect, low catalytic activity, etc., and achieve the effects of simple steps, uniform and controllable morphology, and high catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The preparation steps of the composite nanomaterials in this example are as follows:

[0050] 1) Configuration of the solution: Weigh 1.2358 g (1 mmol) of ammonium molybdate ((NH) 4 ) 6 Mo 7 O 24 ·4H 2 O) and 2.2836 g (30 mmol) thiourea (CH 4 N 2 S) in 35mL ultrapure water, strong magnetic stirring for 30min, obtained ammonium molybdate-thiourea mixed solution. Another weighed 0.176g ascorbic acid (C 6 H 8 O 6 , 97%) powder was added to 10 mL of ultrapure water and dissolved by ultrasonic to obtain 0.1 mol / L ascorbic acid solution. Weigh 1 g of chloroauric acid trihydrate (HAuCl 4 ·3H 2 O, Au23.5-23.8%) powder was added to 80 mL of ultrapure water and dissolved by ultrasonic to obtain 1%wt chloroauric acid solution. Take 1 mL of 1% wt chloroauric acid solution and dilute it with ultrapure water to 5 mL to obtain a 0.2% wt chloroauric acid solution.

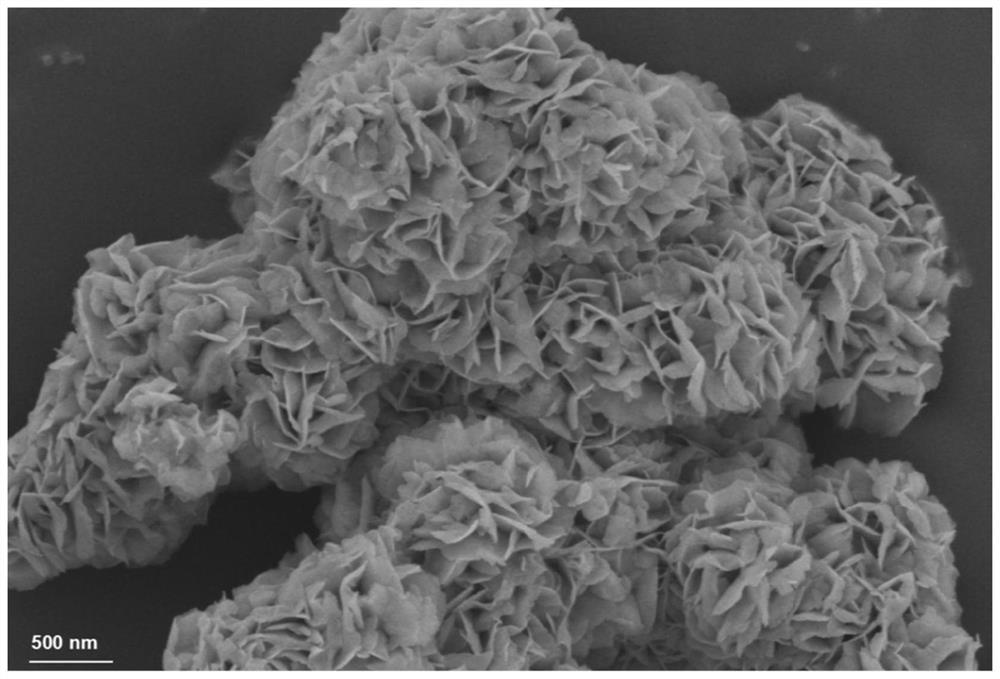

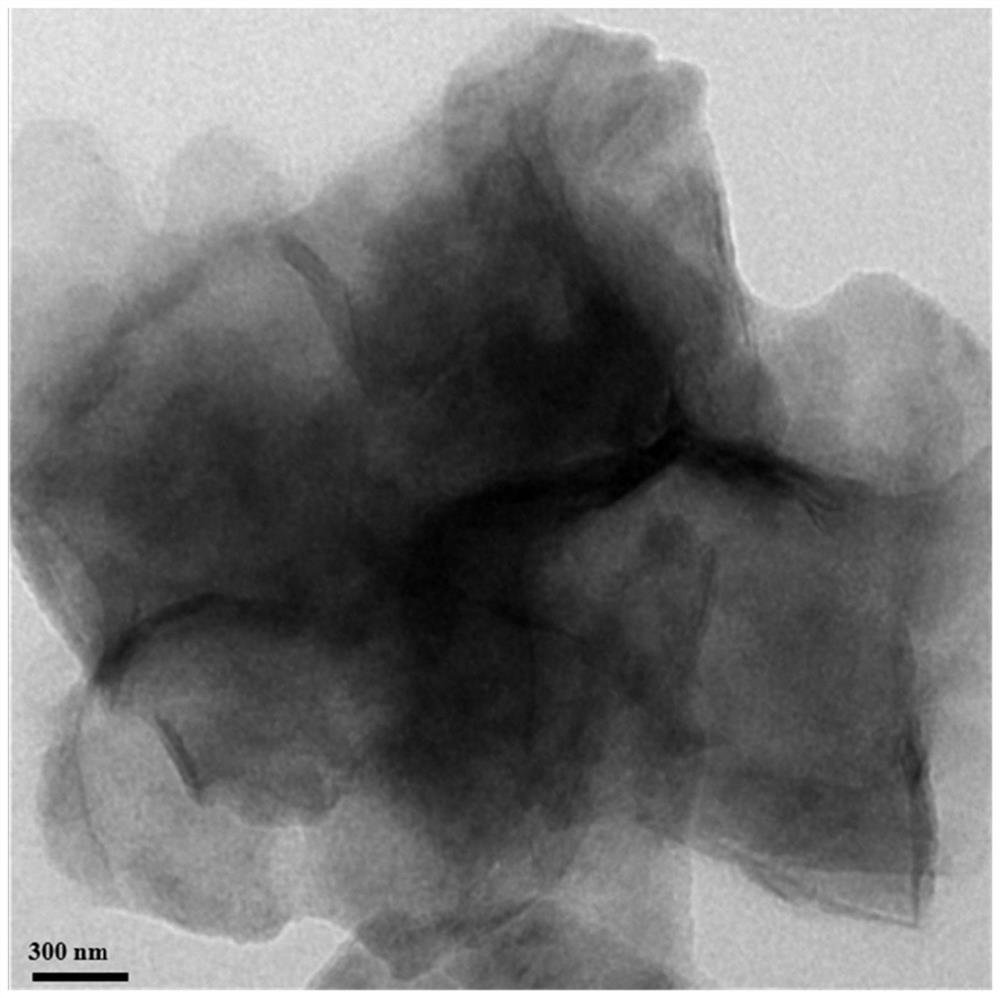

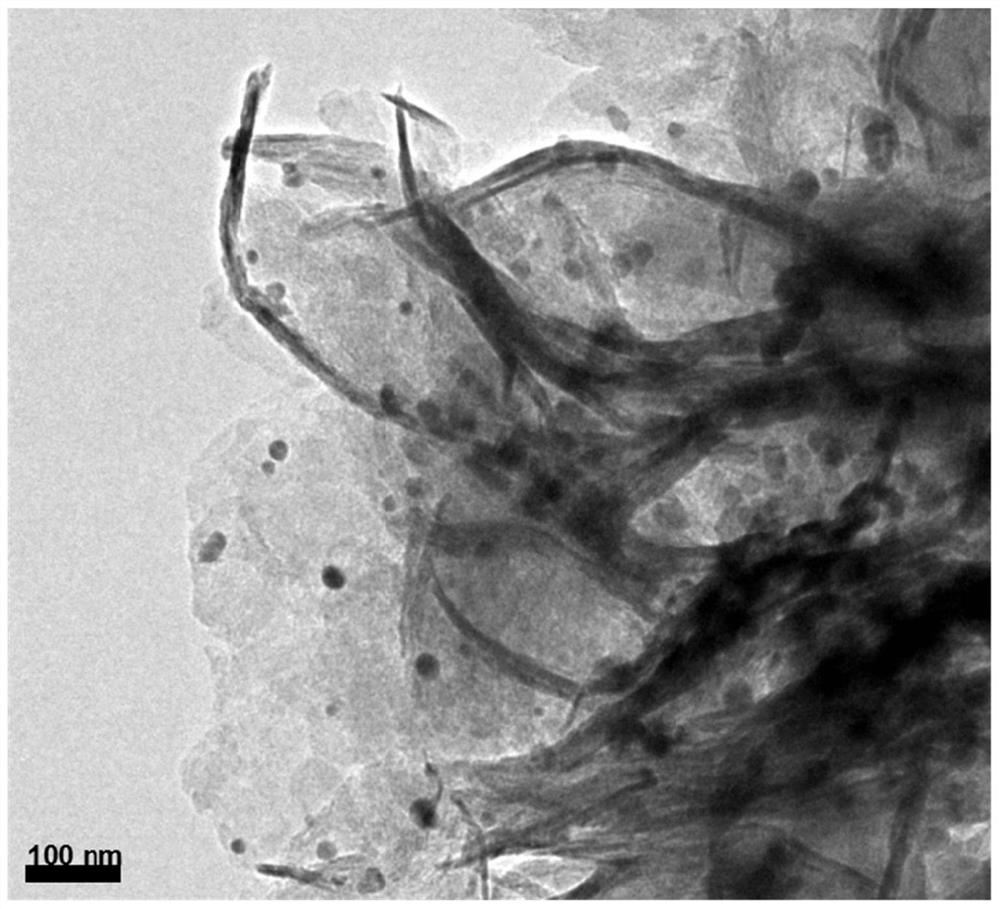

[0051] 2) Preparation of flower-shaped molybdenum disulfide: the above-mentioned ammonium molybdate-thiourea...

Embodiment 2

[0054] The preparation steps of the composite nanomaterials in this example are as follows:

[0055] 1) Configuration of the solution: Weigh 1.2358 g (1 mmol) of ammonium molybdate ((NH) 4 ) 6 Mo 7 O 24 ·4H 2 O) and 2.2836 g (30 mmol) thiourea (CH 4 N 2 S) in 35mL ultrapure water, strong magnetic stirring for 30min, obtained ammonium molybdate-thiourea mixed solution. Another weighed 0.176g ascorbic acid (C 6 H 8 O 6 , 97%) powder was added to 10 mL of ultrapure water and dissolved by ultrasonic to obtain 0.1 mol / L ascorbic acid solution. Weigh 1g potassium tetrachloropalladate (K 2 PdCl 4 , Pd≥32.6) powder was added to 99 mL of ultrapure water and dissolved by ultrasonic to obtain 1wt% potassium tetrachloropalladate solution. Dilute 1 mL of 1 wt% potassium tetrachloropalladate solution to 5 mL with ultrapure water to obtain a 0.2 wt% potassium tetrachloropalladate solution.

[0056] 2) Preparation of flower-shaped molybdenum disulfide: the above-mentioned ammoniu...

Embodiment 3

[0059] The preparation steps of the composite nanomaterials in this example are as follows:

[0060] 1) Configuration of the solution: Weigh 1.2358 g (1 mmol) of ammonium molybdate ((NH) 4 ) 6 Mo 7 O 24 ·4H 2 O) and 2.2836 g (30 mmol) thiourea (CH 4 N 2 S) in 35mL ultrapure water, strong magnetic stirring for 30min, to obtain ammonium molybdate-thiourea mixed solution. Another weighed 0.176g ascorbic acid (C 6 H 8 O 6 , 97%) powder was added to 10 mL of ultrapure water and dissolved by ultrasonic to obtain 0.1 mol / L ascorbic acid solution. Weigh 1 g of chloroauric acid trihydrate (HAuCl 4 ·3H 2 O, Au23.5-23.8%) powder was added to 80 mL of ultrapure water and dissolved by ultrasonic to obtain 1wt% chloroauric acid solution. Dilute 1 mL of 1 wt% chloroauric acid solution with ultrapure water to 5 mL to obtain a 0.2 wt% chloroauric acid solution. Weigh 1g potassium tetrachloropalladate (K 2 PdCl 4 , Pd≥32.6) powder was added to 99 mL of ultrapure water and dissolv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com