Preparation method of fluorescent polystyrene microspheres

A technology of polystyrene microspheres and fluorescence, which is applied in the preparation of microspheres and microcapsule preparations, can solve the problems of wide dye size distribution, unsatisfactory fluorescence stability of fluorescent polystyrene microspheres, and dye quenching, achieving Reduce non-specific adsorption, increase antigen-specific binding ability, and have little environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of fluorescent polystyrene microspheres of the present invention specifically comprises the following steps:

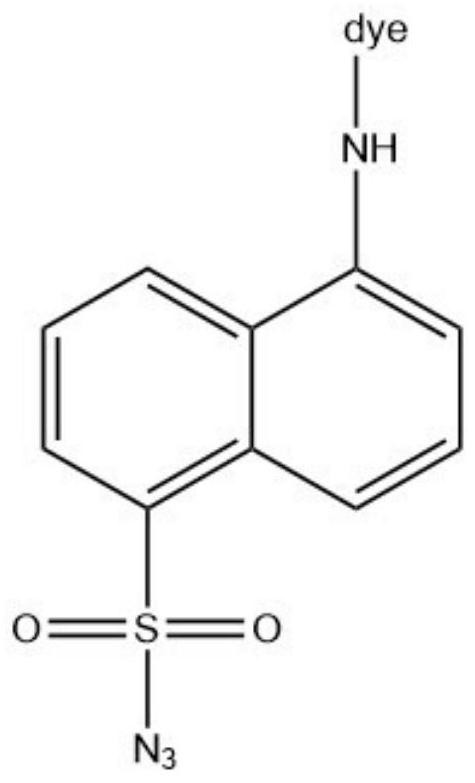

[0027] (1) Preparation of fluorescent dye molecule-coupled azide compound: 10 mg of 5-amino-1-naphthalenesulfonic acid azide compound and 15 mg of acid chloride Cy5 were dissolved in 2 mL of dichloromethane, stirred overnight, and filtered to remove impurities, 30 The organic solvent was removed by rotary evaporation at ℃ without further purification;

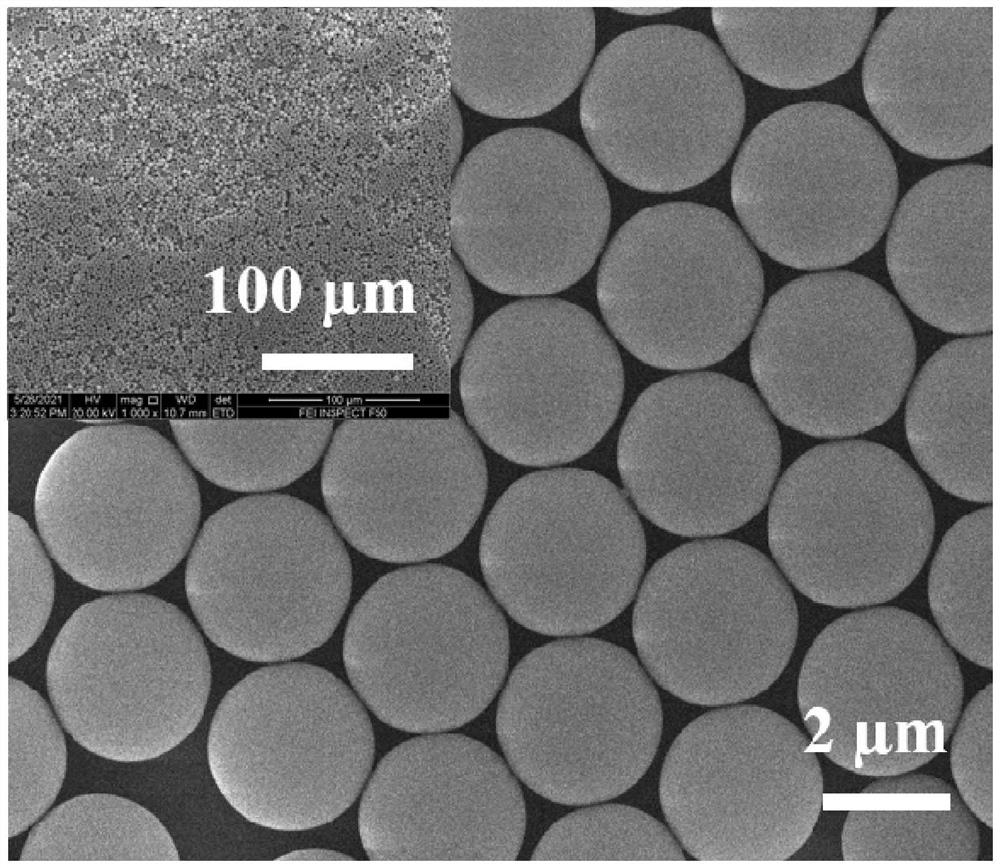

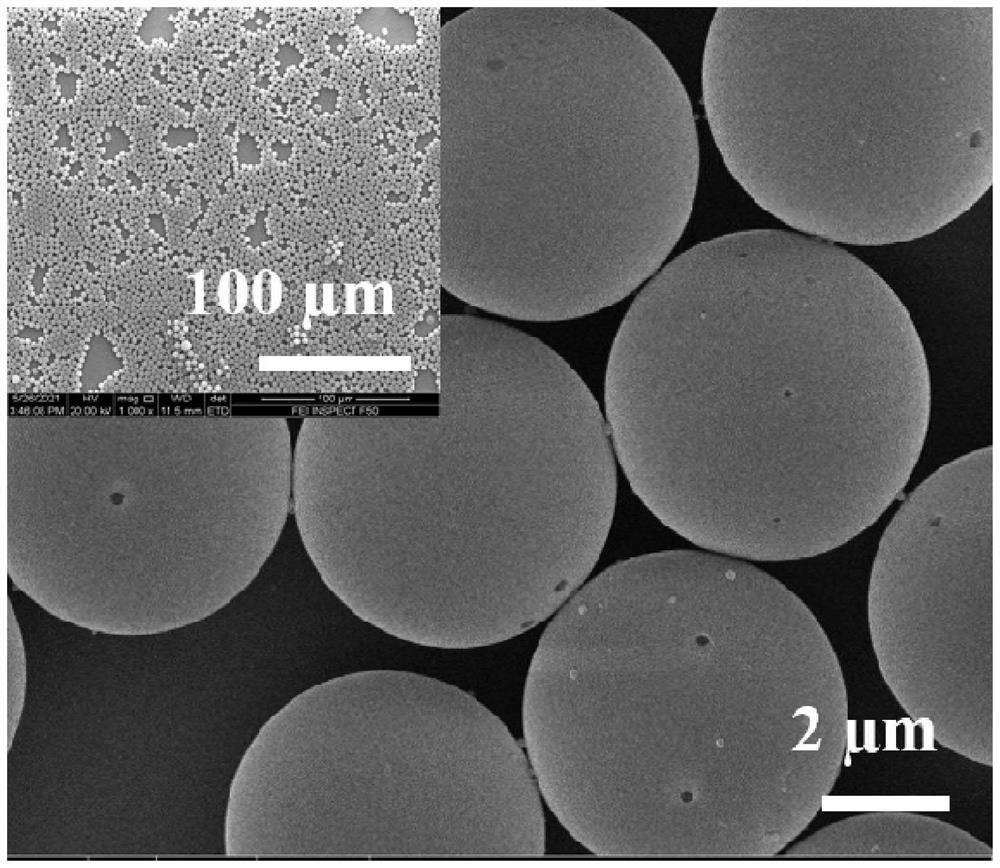

[0028] (2) Preparation of fluorescent encoding microsphere carrier: styrene (2g), divinylbenzene (0.05g), glycidyl methacrylate (0.10g), mono[2-[(2-methyl succinate) -Acryloyl)oxy]ethyl]ester (0.10g) and benzoyl peroxide (0.12g) were respectively emulsified in 30mL of 0.2% SDS solution; then polystyrene seed microspheres (0.1g) Disperse in the above emulsion, stir at 30°C for 12h, then heat at 74°C for 24h, cool down to room temperature after the reaction, and then collect the sample into...

Embodiment 2

[0031] The preparation method of fluorescent polystyrene microspheres of the present invention specifically comprises the following steps:

[0032] (1) Preparation of fluorescent dye molecule-coupled azide compound: 10 mg of 7-amino-4-hydroxy-3-[(4-methoxy-2-sulfophenyl)azo]-2-naphthalenesulfonic acid azide Nitrogen and 15 mg of acyl chloride Cy5 were dissolved in 2 mL of dichloromethane, and after stirring overnight, the impurities were removed by filtration, and the organic solvent was removed by rotary evaporation at 30 °C, without further purification;

[0033](2) Preparation of fluorescent encoding microsphere carrier: styrene (2g), divinylbenzene (0.05g), glycidyl methacrylate (0.10g), mono[2-[(2-methyl succinate) -Acryloyl)oxy]ethyl]ester (0.10g) and benzoyl peroxide (0.12g) were respectively emulsified in 30mL of 0.2% SDS solution; then polystyrene seed microspheres (0.1g) Disperse in the above emulsion, stir at 30°C for 12h, then heat at 74°C for 24h, cool down to ro...

Embodiment 3

[0036] The preparation method of fluorescent polystyrene microspheres of the present invention specifically comprises the following steps:

[0037] (1) Preparation of fluorescent dye molecule-coupled azide compound: 10 mg of 5-(2-aminoethylamine)-1-naphthalenesulfonic acid azide and 15 mg of FITC (fluorescein isothiocyanate) were dissolved in 2 mL of dichloromethane, After stirring overnight, impurities were removed by filtration, and the organic solvent was removed by rotary evaporation at 30°C, without further purification;

[0038] (2) Preparation of fluorescent encoding microsphere carrier: styrene (2g), divinylbenzene (0.05g), glycidyl methacrylate (0.10g), mono[2-[(2-methyl succinate) -Acryloyl)oxy]ethyl]ester (0.10g) and benzoyl peroxide (0.12g) were respectively emulsified in 30mL of 0.2% SDS solution; then polystyrene seed microspheres (0.1g) Disperse in the above emulsion, stir at 30°C for 12h, then heat at 74°C for 24h, cool down to room temperature after the react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com