Divalent europium sulfide near-infrared scintillator and preparation method thereof

A sulfide, near-infrared technology, applied in the preparation/processing of rare earth metal compounds, rare earth metal sulfides, chemical instruments and methods, etc., can solve problems such as easy deliquescence, and achieve simple preparation methods, high radiation resistance and humidity. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

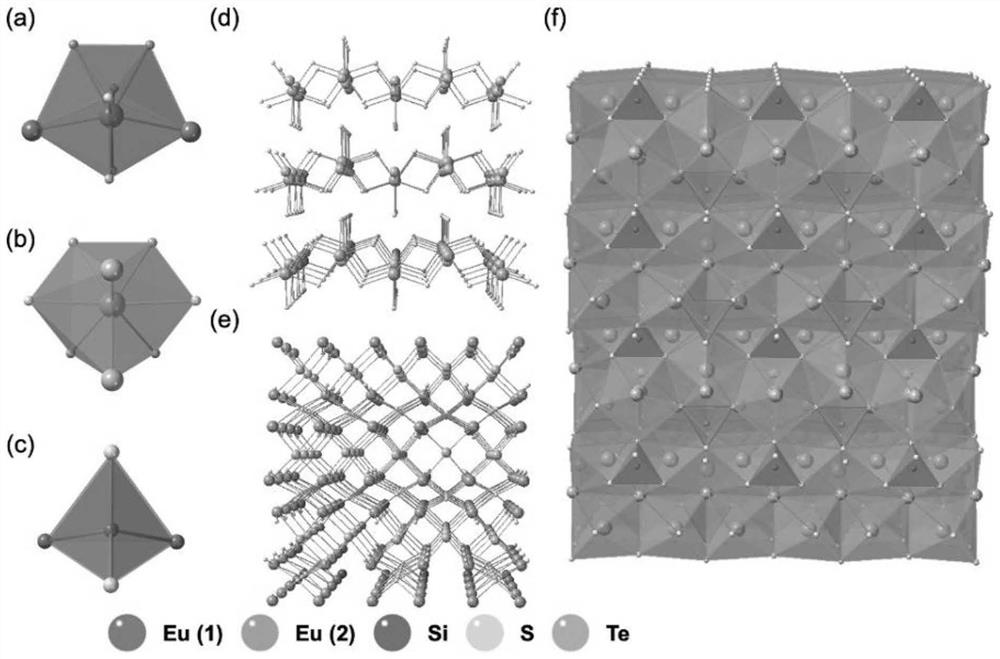

[0037] Example 1: Synthesis of divalent europium sulfide near-infrared scintillator Eu3 SiS 4 Te

[0038] According to the ratio of 3:1:4.4:1, put europium oxide, silicon powder, sulfur powder, tellurium powder, boron powder and excess cesium chloride co-solvent in a mortar, fully grind them and transfer them to a quartz tube. Seal with oxyhydrogen machine. The sample was then placed in a muffle furnace, heated to 950° C. in half a day, and then slowly lowered to room temperature after three days of maintenance. After ultrasonic cleaning of the product with deionized water and ethanol, drying was performed at room temperature to obtain the product Eu 3 SiS 4 Te.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com