Thermoplastic material capable of being chemically degraded and recycled and preparation method thereof

A thermoplastic material and chemical degradation technology, applied in the field of polymer material synthesis, can solve the problems of waste of resources and low recycling rate of thermoplastic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058]Based on the chemically degradable and recyclable thermoplastic material provided above, the present invention also provides a method for preparing a chemically degradable and recyclable thermoplastic material, comprising:

[0059] The cyclooctene monomer and the diene monomer or the cyclooctene monomer and the polyolefin monomer are contacted under the action of the second-generation Grubbs catalyst, and the intermediate is obtained by metathesis and copolymerization;

[0060] The intermediate is hydrogenated with hydrogen to obtain a thermoplastic material that can be chemically degraded and recycled;

[0061] Wherein, the chemically degradable and recyclable thermoplastic material has the general structural formula shown in formula (I):

[0062]

[0063] Wherein, X is selected from one or more diene monomers or polyolefin monomers selected from esters, acid anhydrides, phosphines, silyl ethers, amides and ethers; n and m are both positive integers ; n represents t...

Embodiment 1

[0070] Example 1 (preparation of chemically degradable recycled thermoplastic material):

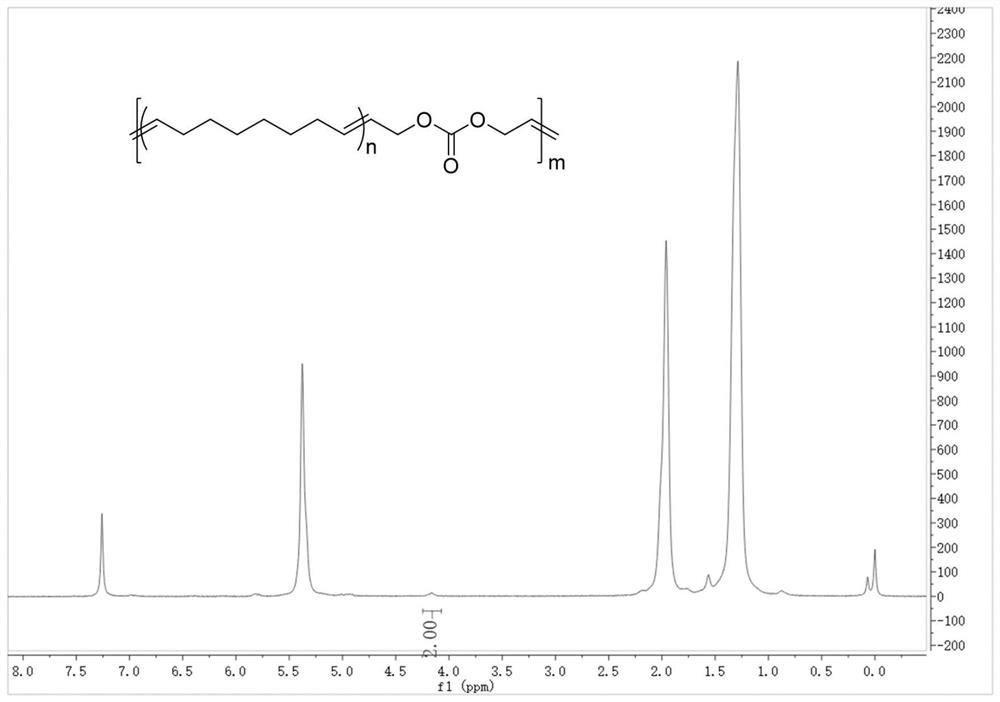

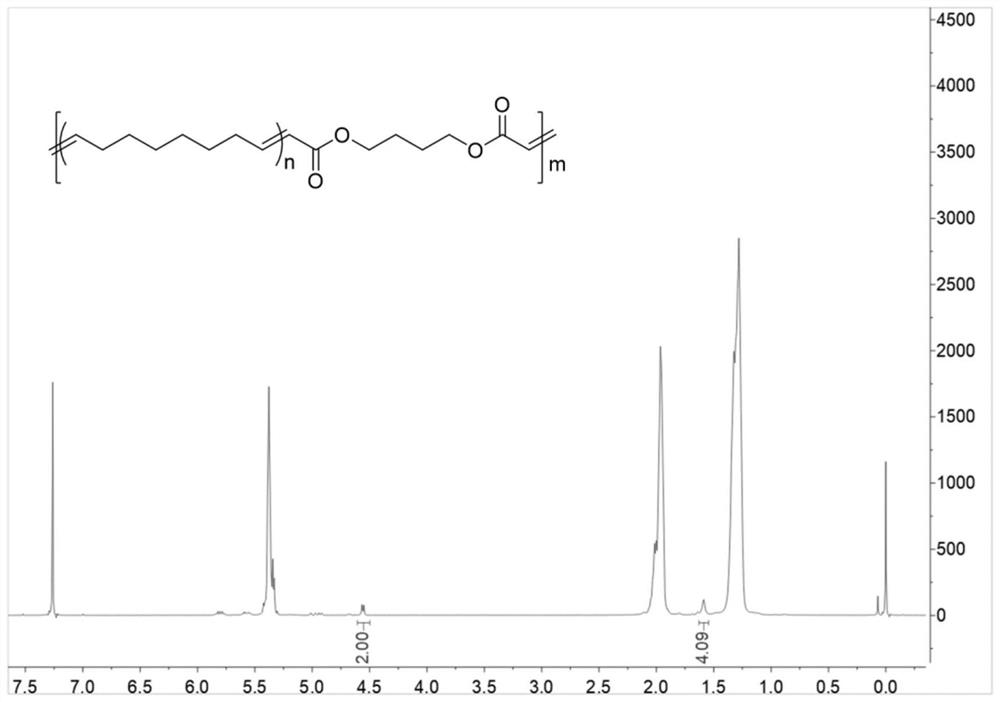

[0071]

[0072] Under nitrogen atmosphere, in a 100mL reaction flask (from Schlenk), add cyclooctene monomer (15mmol, 1.7g), diene monomer (0.015mmol) and 40mL anhydrous dichloromethane, put the reaction flask into In an oil bath at 40°C, the second-generation Grubbs catalyst (4 μmol, 3 mg) was dissolved in 1 mL of dichloromethane (DCM), and injected into the reaction flask, and the reaction was continued for 3 h. After the reaction was completed, the solvent was concentrated and added. 100 mL of methanol was used to separate out the polymer, which was filtered, washed and dried. Then the dried polymer was added to the autoclave, 40 mL of toluene solvent and tris(triphenylphosphine) rhodium chloride (10 μmol, 9 mg) catalyst were added, the reactor was closed, and H 2 , adjust the pressure to 20atm, after 5h of reaction, remove H 2 , 100 mL of methanol was added to the reaction kettl...

Embodiment 2

[0081] Example 2 (Degradation and Recovery of Chemically Degradable Recyclable Thermoplastics):

[0082] The chemically degradable and recyclable thermoplastic material prepared by the above-mentioned embodiment is put into a beaker, and a hydrochloric acid solution or a sodium hydroxide solution or a tetrabutylammonium fluoride solution is added. After heating under reflux for 5 hours, the material was completely degraded and dissolved in the solution, the solution was concentrated, methanol was added to separate out the recovered polymer, and the recovered polymer was dried.

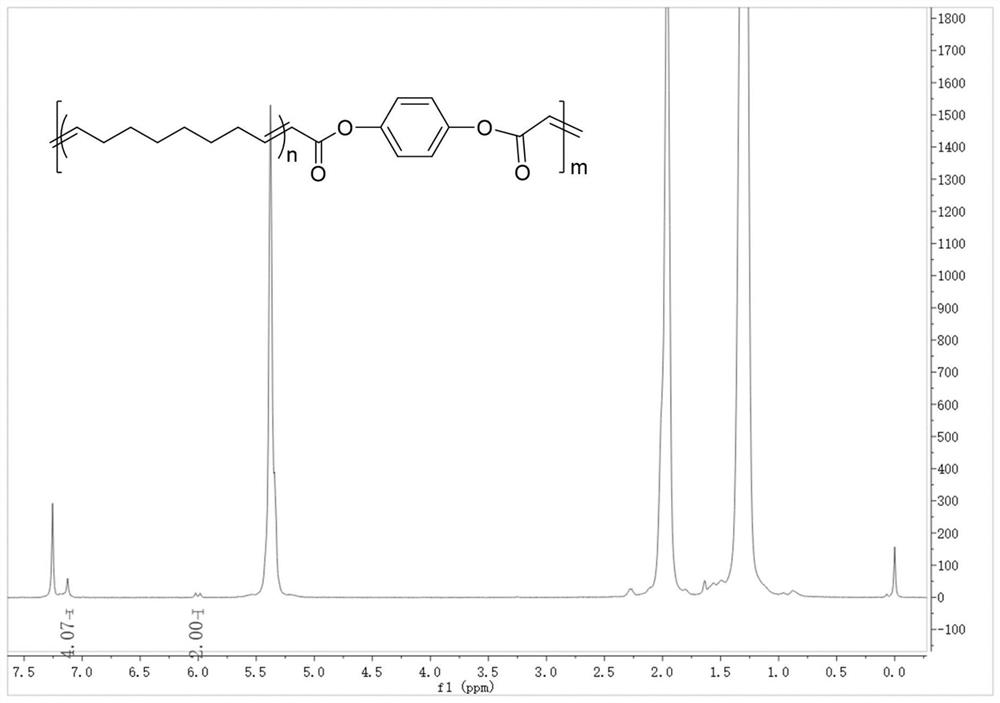

[0083] like image 3 As shown, it can be seen that the chemically degradable and recyclable thermoplastic material prepared by the diene monomer numbered M2 and the cyclooctene monomer can break the ester bond and complete the degradation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stress | aaaaa | aaaaa |

| Stress | aaaaa | aaaaa |

| Stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com