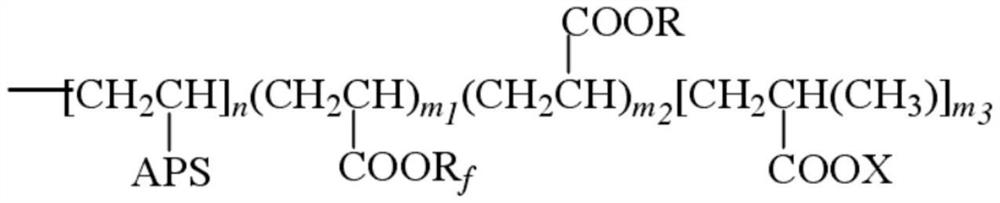

Organic silicon modified fluorinated polyacrylate emulsion, preparation method thereof, prepared unconventional energy drilling and production coating and application thereof

A technology of polyacrylate emulsion and perfluoropolyether methacrylate, which is applied in coating, climate sustainability, sustainable manufacturing/processing, etc., and can solve the problem of high surface energy, poor water-repelling effect, etc. problems, to achieve the effect of improving adhesion, improving hydrophobic effect, and strong bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Another purpose of the present invention is to provide a method of preparing a silicon -alternative fluorine polyacrylate lotion, including the following steps:

[0034] Performor acrylic, pomestin hydrofluorrite methyl acrylate, ethylene trimal oxygenne, and methyl acrylic ondeene for the first mixing to obtain the first mixture;

[0035] Add emulsifier to the first mixing material, mix well to get pre -emulsion;

[0036] Discover the water solution with water to obtain water solution;

[0037] Under the condition of protecting the atmosphere, add a 1 / 4 volume of pre -emulsion and 1 / 4 of the water solution of 1 / 4 volume to perform a second mixing, reflect to the system pan -blue light, control the speed drip plus the remaining emulsion and the water solution, the insulation reaction, the insulation reaction, the insulation reaction , The pH of the regulating system is 6-7, and the white lotion that obtains a pan-blue light is the fluorine polyacrylate emulsion with silicon...

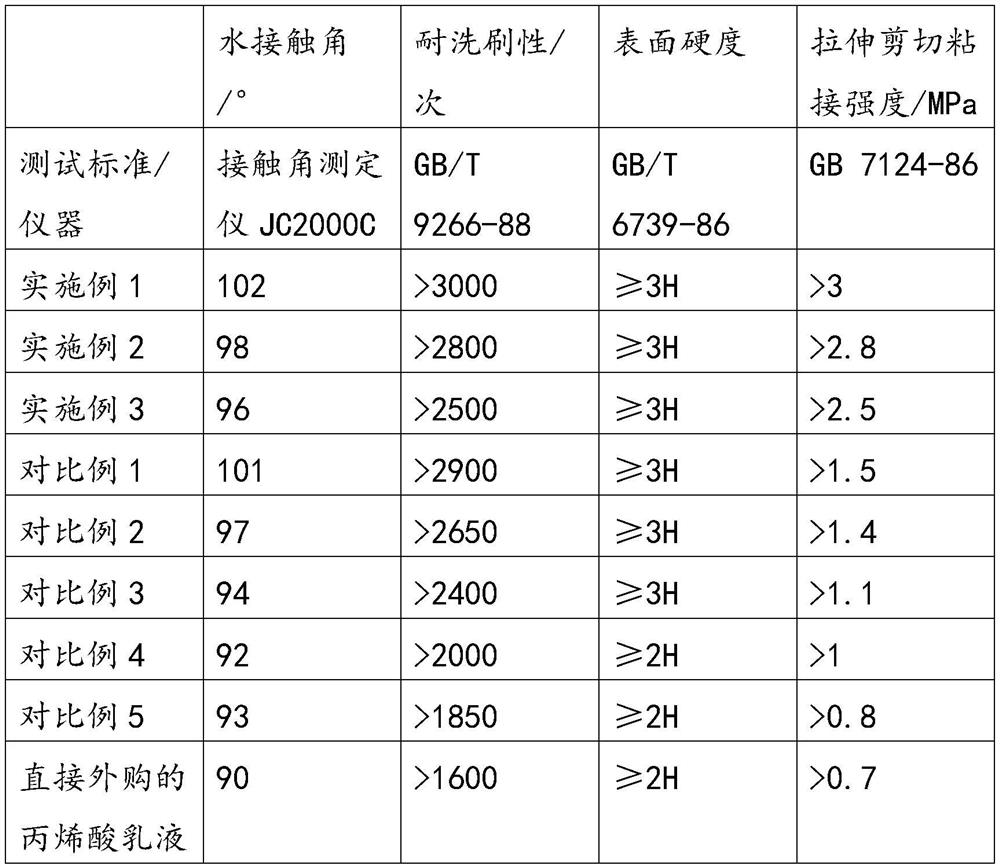

Embodiment 1

[0061] 1. In the bottle bottle, it is referred to as the 15 weight of methyl acrocylite (LMA), the total fluoride polyetheryl acrylic (FA) 80 weight, the ethylene triathylsiline 2 weight, the methacryal acrylic acid 3 weights of orthodoxyl ester, then heat to 60 ° C, 100rpm and stir 1.5h, so that each component is liquid and mix, and then add 0.5 weight emulsiflower methyl acrocyloxide trigen chloride to the above mixture. Actinium to make pre -emulsion.

[0062] Take 0.5 weights to cause the aimal nitrogen diced (AIBN), add 50 weight water, dissolved to make the water solution that causes the water solution, and set aside.

[0063] 2. In the four -port bottle, first add 1 / 4 volume of pre -emulsion and 1 / 4 volume of the water solution of the 1 / 4 volume of step 1, stir 1.5h at 100rpm, pass n 2 Protection, warming to 75 ° C, reaction to the significant pan -blue light.

[0064] Then add the remaining pre-emulsion and the water solution of the surplus emulsion to control the drip spe...

Embodiment 2

[0067] 1. In the burning bottle, in turn, the weight of methyl acrylic (LMA) 17 weights, all -fluorophytal methyl acrylic (FA) 85 weight, ethylene triathylsililane 3 weight, methyl acrylic acid 3 weight Positive butyl ester 4 weights, then heat to 70 ° C, 150rpm stirring for 2h, so that each component is liquid and mix, and then add 0.8 weight emulsiflower methacrythyl acrocyl othic chloride to the above mixture. Ammonium, pre -emulsion.

[0068] Take 0.6 weights to cause the aid nitrogen diced (AIBN), add 60 weight water, dissolved to make the water solution that causes the water solution, and set aside.

[0069] 2. In the four -port bottle, first add 1 / 4 volume of pre -emulsion and 1 / 4 volume of the water solution of the 1 / 4 volume of the step 1, stir at 150rpm for 2h, pass n 2 Protection, warming to 80 ° C, reaction to the obvious pan -blue light.

[0070] Then add the remaining pre-emulsion and the water solution of the surplus emulsion to control the drip speed of the two, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com