Electrochromic copolymer containing dioxythiophene and 9, 9-spirobifluorene structure, preparation method of electrochromic copolymer and polymer film

A technology of polymer film and dioxythiophene, which is applied in the fields of instruments, optics, nonlinear optics, etc., can solve the problems that have not been reported on polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation method of the electrochromic copolymer containing dioxythiophene and 9,9'-spirobifluorene structure is:

[0032] (1) Synthesis of 3,4-ethylenedithiothiophene

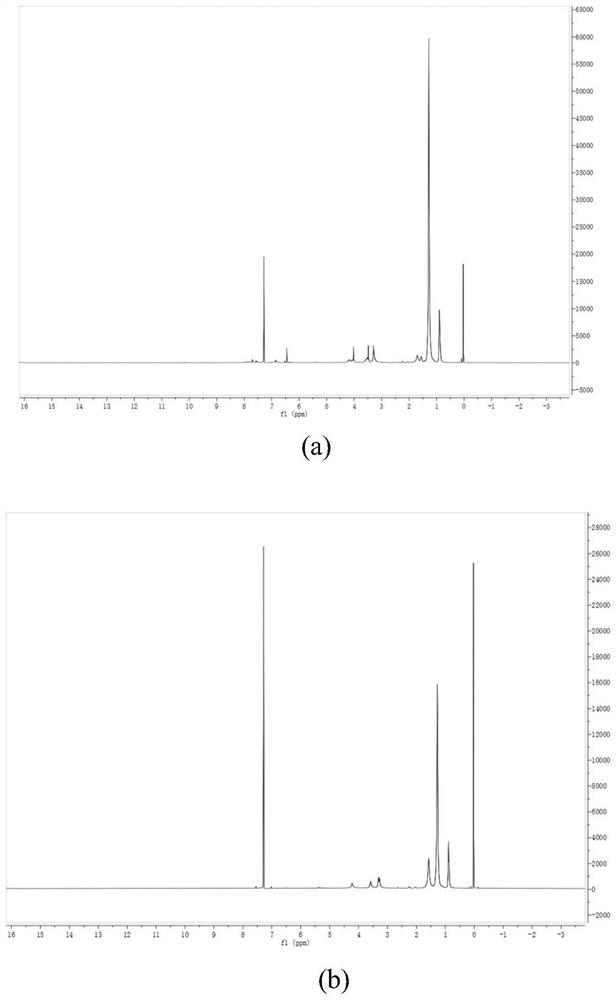

[0033] Dissolve 0.1 mol of 3,4-dimethoxythiophene, 0.15 mol of 1,2-ethanedithiol and 0.001 mol of p-toluenesulfonic acid-hydrate in 200 mL of toluene, place it in a 500 mL single-neck flask, and connect the tape Soxhlet extractor and condenser tube with molecular sieve. The reaction was stirred at reflux for 24 hours, then cooled to room temperature, poured into water, and the organic phase was collected by separation. The aqueous phase was extracted twice with 20 mL of dichloromethane. Pass through a silica gel column, the eluent is dichloromethane / n-hexane (1:1), and a white solid is obtained with a yield of 76%; 3 , δ, ppm): 3.24 (s, 4H), 6.99 (s, 2H).

[0034] (2) Synthesis of 2,5-dibromo-3,4-ethylenedithiothiophene

[0035] Dissolve 0.1 mmol of 3,4-ethylenedithiothiophene in 20 mL of chlo...

Embodiment 2

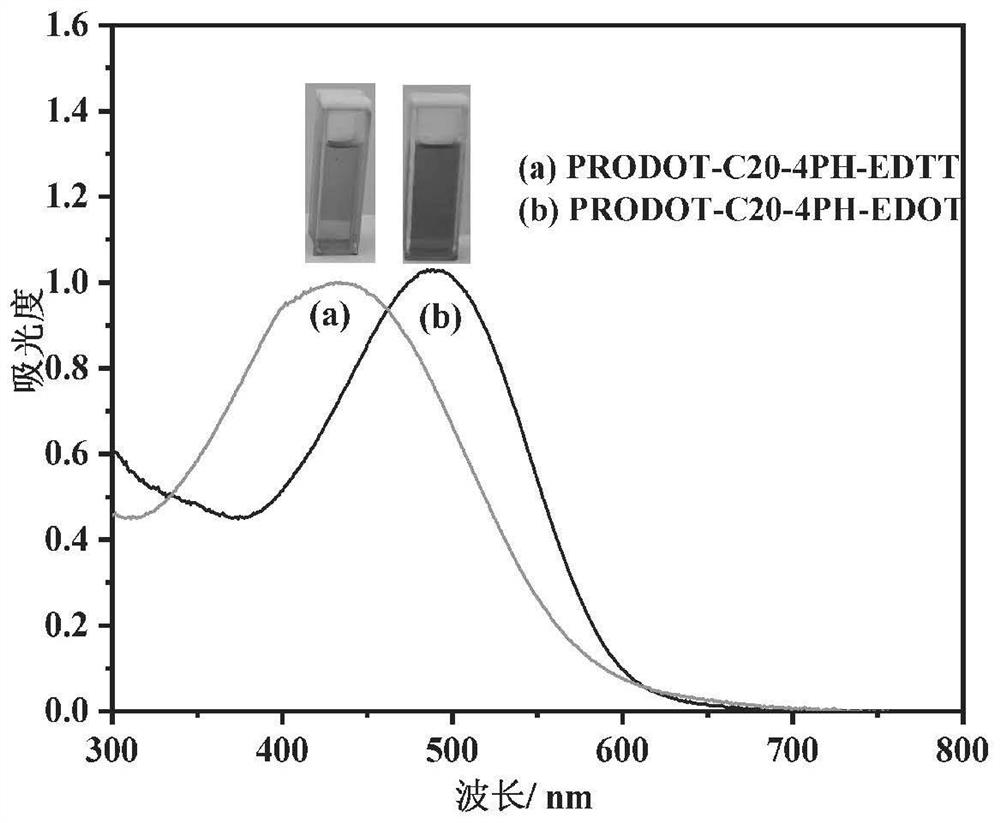

[0041] The polymer prepared in Example 1 was tested by solution spectrum and electrochemical performance. Dissolve the polymer in dichloromethane to prepare a concentration of 2*10 -4 mg / mL solution, the solution absorption curve is as follows figure 2 As shown, the polymer P(PRODOT-C20-4PH-EDTT) and P(PRODOT-C20-4PH-EDOT) solutions appear orange-yellow and orange-red, respectively. Through the test of UV-Vis spectrophotometer, the corresponding absorption peaks of the solution are at 434nm and 488nm, respectively.

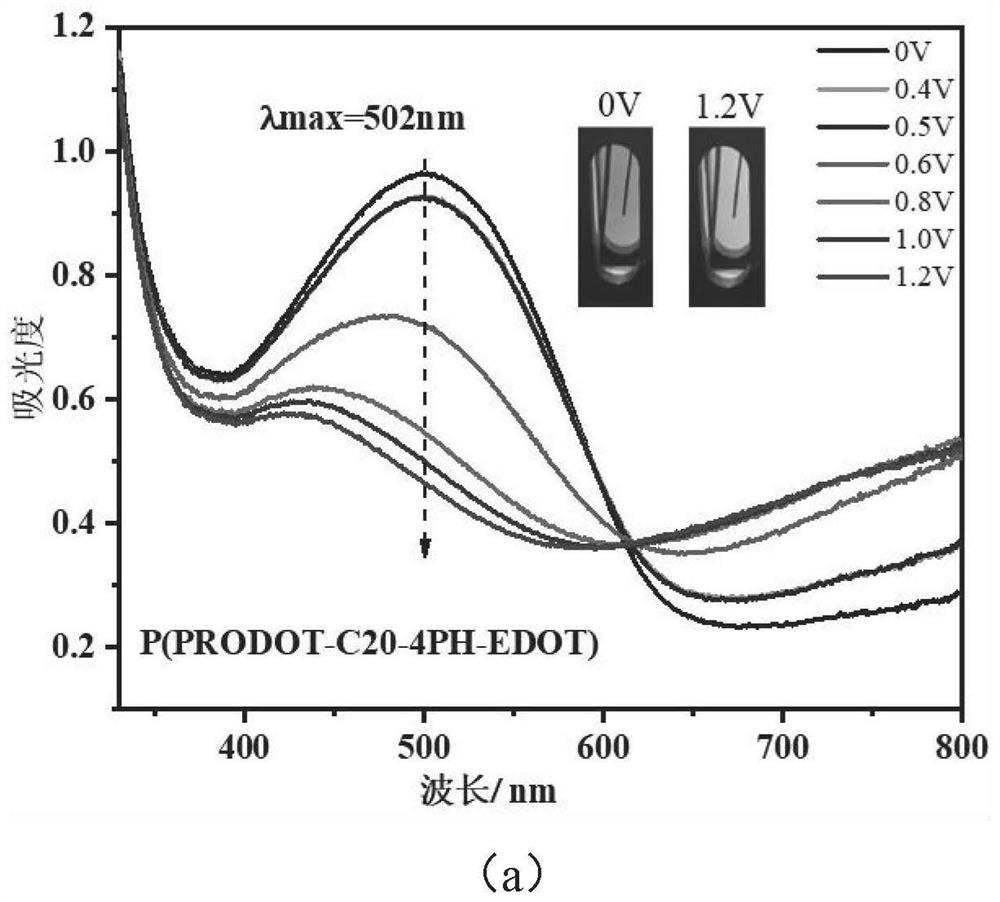

[0042] Preparation of polymer film: Dissolve the polymer in chloroform to prepare a solution of 2 mg / ml, filter out the insoluble matter through a filter, then place it in a spray gun, control the air pressure to 2 MPa, and spray it on conductive glass. The absorbance of the film is about 0.8 , After spraying, put it in a vacuum drying box for drying at 40 degrees vacuum for use. A three-electrode system with a polymer membrane as the working electrode, a plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com