Novel biomass synthesis gas directional preparation and blast furnace smelting coupling co-production process

A blast furnace smelting and biomass technology, which is applied in the field of blast furnace smelting, can solve the problems of low melting point of biomass ash, corrosion, and high requirements for gasification equipment, and achieve the effects of reducing heat loss, production cost, and transportation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

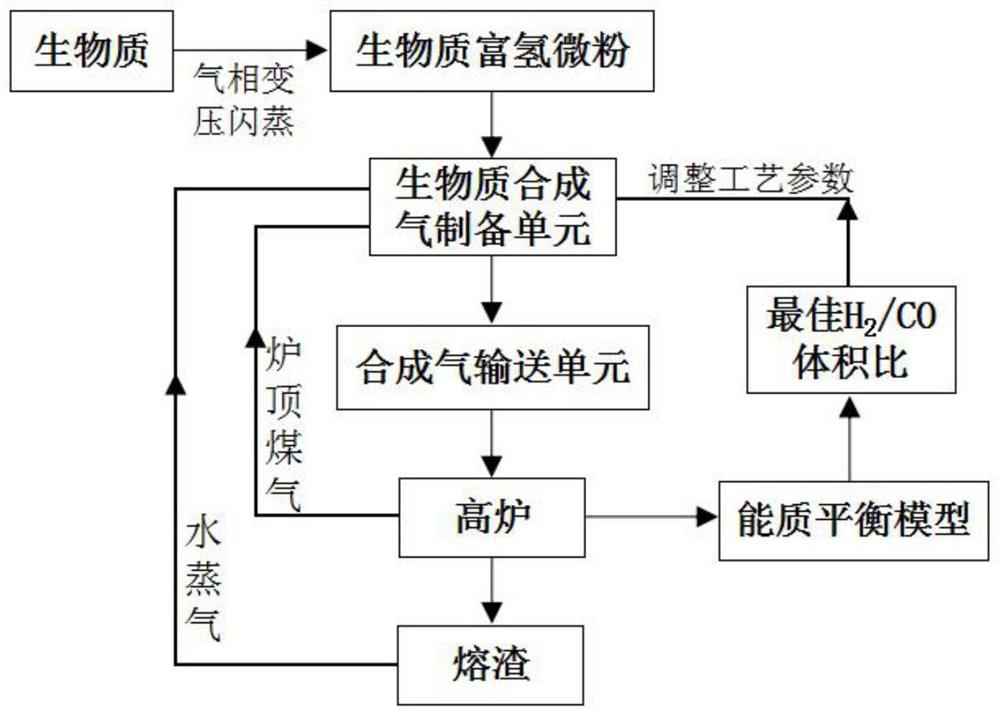

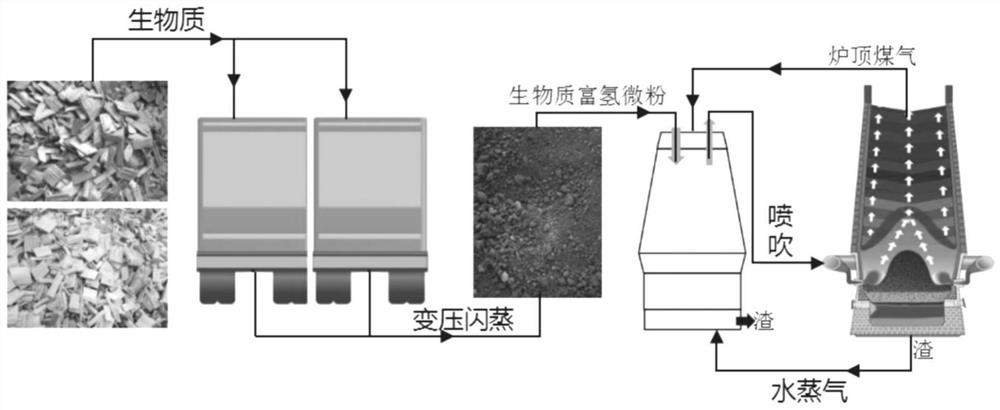

[0047] see figure 2 As shown, the present implementation provides a new process for the directional preparation of biomass synthesis gas and the coupled co-production of blast furnace smelting, including the following steps:

[0048] S1. Construct a coupling system for the directional preparation of biomass synthesis gas and blast furnace smelting, including a biomass synthesis gas preparation unit, a synthesis gas conveying unit and a blast furnace that are connected in sequence; the synthesis gas conveying unit is communicated with the injection system of the blast furnace; the top of the blast furnace The gas outlet is communicated with the gasification agent inlet of the biomass synthesis gas preparation unit;

[0049] S2. Establish a flow evolution path model of ferrite flow and carbon flow in combination with blast furnace raw material composition, preset pig iron composition, and blast parameters, and establish an energy-mass balance model according to heat income and ...

Embodiment 2

[0054] This embodiment provides a new process for the directional preparation of biomass synthesis gas and the coupled co-production of blast furnace smelting. Compared with Embodiment 1, the difference is that the raw material for preparing biomass synthesis gas is ordinary biomass (C, H, The content of O element is 47wt%, 6wt%, 35wt% respectively); the rest are roughly the same as in Example 1, and will not be repeated here.

[0055] Each component CO of furnace top gas collected in the blast furnace smelting process in Example 2 2 , water vapor, CO and H 2 The content of 25.0%, 12.1%, 46.2%, 16.2%, respectively, after the blast furnace gas and slag water-cooled, the hot water vapor produced by water cooling is transported to the gasifier, and the process parameters of the biomass synthesis gas preparation unit are adjusted: the gasification temperature is 1200℃, solid phase residence time is 3min, additional water vapor is required, after adding water vapor, the mass ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com