Corrosion-resistant aluminum-carbon composite material and preparation method thereof

An aluminum-carbon composite material and corrosion resistance technology, applied in the field of composite material preparation, can solve the problems of weakening macroscopic corrosion resistance, aggravating the heterogeneity of composite materials, crevice corrosion, etc. , Improve the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

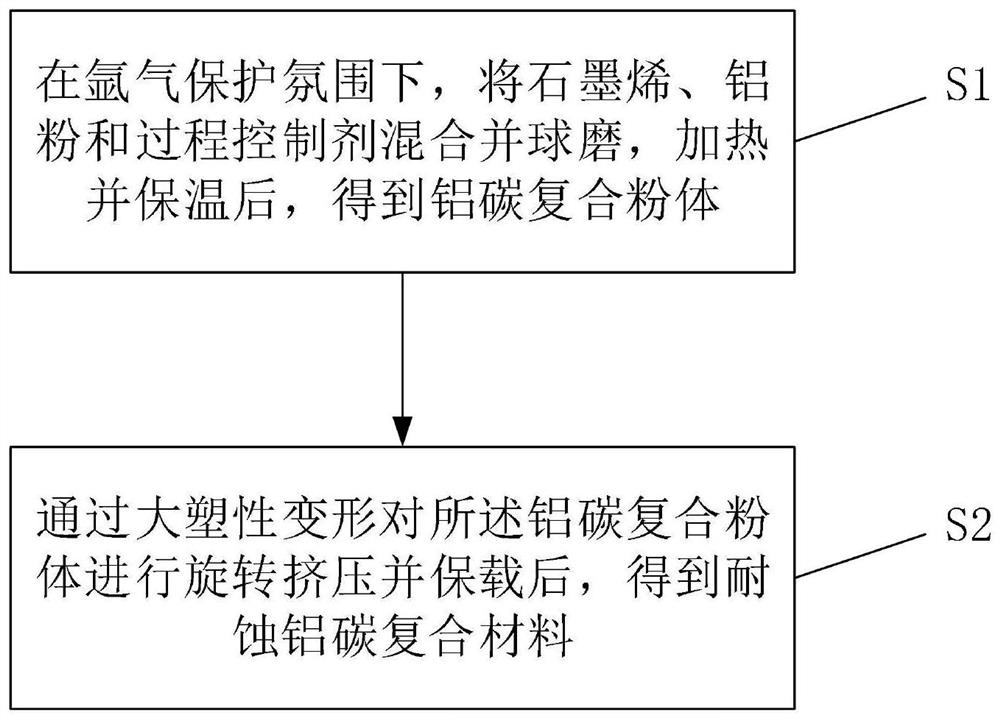

[0026] like figure 1 As shown, a method for preparing a corrosion-resistant aluminum-carbon composite material according to an embodiment of the present invention includes the following steps:

[0027] Step S1: under the protective atmosphere of argon, the graphene, the aluminum powder and the process control agent are mixed and ball-milled, and after heating and heat preservation, the aluminum-carbon composite powder is obtained;

[0028] Step S2: After the aluminum-carbon composite powder is rotationally extruded and held by large plastic deformation, a corrosion-resistant aluminum-carbon composite material is obtained.

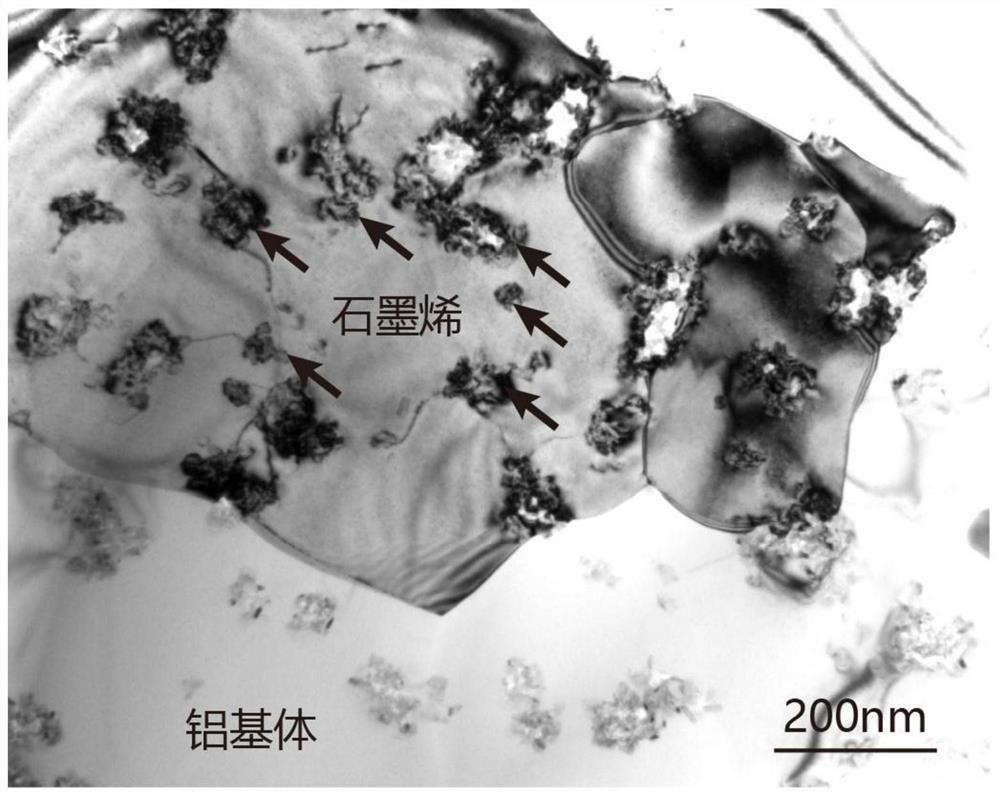

[0029] In the embodiment of the present invention, graphene, aluminum powder and process control agent are mixed and ball-milled, and then the aluminum-carbon composite powder is rotationally extruded and held by large plastic deformation, so that graphene is broken and peeled off in the aluminum matrix. , redistribute, realize super-homogeneous distributi...

Embodiment 1

[0049] In the present embodiment, the corrosion-resistant aluminum-carbon composite material is prepared by the preparation method of the corrosion-resistant aluminum-carbon composite material, and the specific steps are as follows:

[0050] Step S1: weigh 0.3 g of thin-layer graphene nanosheets and 19.7 g of 1060 industrial pure aluminum powder in a high-purity argon-protected glove box (water and oxygen < 0.01 ppm), put them into a vacuum-sealed stainless steel ball mill, and then place them in a vacuum-sealed stainless steel ball mill. The stainless steel ball milling jar is sealed in the glove box and taken out for ball milling, and then placed under the protection of high-purity argon and heated to 450 ° C and kept for 0.5 h, until the process control agent is completely volatilized, and the pre-mixed aluminum-carbon composite powder is obtained; among them, graphite The number of layers of the alkene nanosheets is 5-15 layers, the average particle size of the pure aluminu...

Embodiment 2

[0055] In the present embodiment, the corrosion-resistant aluminum-carbon composite material is prepared by the preparation method of the corrosion-resistant aluminum-carbon composite material, and the specific steps are as follows:

[0056] Step S1: Weigh 0.3 g of graphene fluoride, 18.6 g of 1060 pure aluminum powder and 1.1 g of 99.9% pure magnesium powder in a high-purity argon-protected glove box (water and oxygen < 0.01 ppm) to form an Al-Mg alloying system , put it into a vacuum-sealed stainless steel ball mill, and add about 0.8g polyethylene glycol (Mn 2000) as a process control agent, seal the ball mill in a glove box and take it out for ball milling, and then place it under high-purity argon protection It is heated to 400 °C and kept for 1 h until the process control agent is completely volatilized, and a pre-mixed aluminum-carbon composite powder is obtained; wherein the number of layers of fluorinated graphene is 5-15 layers, and the average particle size of the pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com