Absorbable artificial dura meter of brain and its preparing process

A technology of artificial dura mater and dura mater, which is applied in the field of preparation of layered structure products, can solve the problems of inability to process mesh scaffolds, fibrosis, brain adhesion, etc., and achieve good biocompatibility, absorbability, and degradation speed Slow down and lighten the effect of inflammatory response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

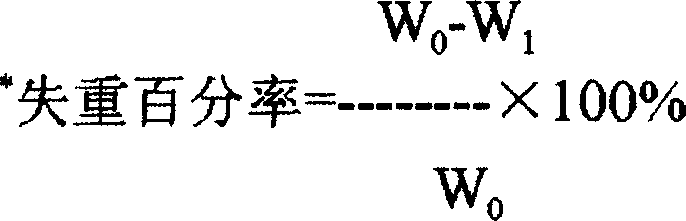

Method used

Image

Examples

Embodiment 1

[0022] The Vicryl net is placed on the glass plate of the horizontal mould, and after flattening, the prepared 3% chitosan mixed solution containing a small amount of glycerin, gelatin, norfloxacin (chitosan powder 320 orders, deacetylation degree 85%, 30 grams, dissolved in 1000 ml of 1% glacial acetic acid solution, fully stirred and dissolved to make 3% chitosan solution, left to stand for 24 hours, took its filtrate, then added 5 ml of glycerin, 30% 7 milliliters of gelatin, 3 grams of norfloxacin, stir well to get chitosan solution. Pour into the surface of the Vicryl net, flatten the horizontal salivation, its thickness is 2-6 mm, put it in a drying oven at 40 ° C for 24 Take it out from the mold after 1 hour, put it in 5% sodium hydroxide solution and soak it for 1 hour, then rinse it with distilled water, soak it for 1 hour, take it out, flatten it at 40°C and put it in a drying oven at 40°C for 2 hours Serve as artificial dura mater, its thickness is 0.03 millimeters,...

Embodiment 2

[0024] In order to be suitable for mechanized industrial production, the horizontal salivation method of embodiment 1 can be replaced by the horizontal spraying method, that is, the material of the polylactic acid net is woven into a polylactic acid weaving cloth of 80 × 1000 centimeters, and it is placed on a horizontal platform after being flattened. The method of embodiment 1 is configured into 3% chitosan mixed solution, carries out horizontal spraying with the coating spray head that American Nuoyan letter company produces, and its thickness is controlled by computer to be 3 millimeters, obtains 0.20 millimeters thick composite film after drying, then use embodiment The artificial composite film can be obtained by neutralizing, washing, drying, cutting, packaging, and γ-ray disinfection according to the method of 1. It can be used for the repair of abdominal wall defect.

Embodiment 3

[0026]First spray the copolymer of lactic acid and glycolic acid (90:10 molar ratio) on the surface of the non-woven fabric coating drum at high temperature (300°C) and high pressure (400 atmospheres) to make polylactic acid non-woven fabric, and then use The prepared 3% chitosan mixed solution of embodiment 1 is poured on the surface of the non-woven fabric, and the horizontal salivation is flattened, and after being dried in a drying oven at 40°C, the artificial dura mater is formed, the thickness is 0.30 mm, and the dry film strength is 120Mpa, the wet film strength is 80Mpa, the water absorption rate is 160%, the seam tension is 700 grams, and the water permeability rate is 0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com