Organocuprous precursors for chemical vapor deposition of copper film

An organic and cuprous technology, used in copper organic compounds, liquid chemical plating, gaseous chemical plating, etc., can solve the problems of poor copper film quality and difficult to handle solid precursors, and achieve high volatility and good thermal stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: the synthesis of (hfac) Cu (I) (DMB)

[0027] 0.5g (3.5mmol) of Cu 2 O and 0.84g (7.0mmol) of MgSO 4 Charge it into a Schlenk flask, and add 30 ml of diethyl ether (the diethyl ether has been distilled by sodium benzophenone under an argon atmosphere), and then slowly add 0.59 g (7.0 mmol) of 3,3-dimethyl-1 -butene. The resulting reddish suspension was stirred for 1 hour and cooled to 0 °C, to which 1.46 g (7.0 mmol) of 1,1,1,5,5,5-hexafluoro-2,4 - A solution of pentanedione (Hhfac) in diethyl ether. The resulting mixture was stirred at room temperature for 2 hours, and at the same time the color of the mixture changed to dark green. The resulting solution was passed through the CELLITE TM The solvent was removed under reduced pressure to obtain 1.74 g of the title compound as a dark green liquid (yield 70%). 1 H-NMR (CDCl 3 , ppm) δ6.12 (s, 1H), 5.38 (m, 1H), 4.30 (dd, 2H), 1.15 (s, 9H) 13 C-NMR (CDCl 3 , ppm) δ177.83 (q, CF 3 COCH), 119.73, 115...

Embodiment 2

[0028] Embodiment 2: the synthesis of (hfac) Cu (I) (TBA)

[0029] 0.5g (3.5mmol) of Cu 2 O and 0.84g (7.0mmol) of MgSO 4Charge it into a Schlenk flask, and add 30 ml of diethyl ether (the diethyl ether has been distilled by sodium benzophenone under an argon atmosphere), and then slowly add 0.58 g (7.0 mmol) of 3,3-dimethyl-1 - Butyne. The resulting reddish suspension was stirred for 1 hour and cooled to 0 °C, to which 1.46 g (7.0 mmol) of 1,1,1,5,5,5-hexafluoro-2,4 - A solution of pentanedione (Hhfac) in diethyl ether. The resulting mixture was stirred at room temperature for 2 hours, and at the same time the color of the mixture turned yellow. The resulting solution was passed through the CELLITE TM The bed was filtered and the solvent was removed under reduced pressure to afford 1.75 g of the title compound as a yellow solid (73% yield). 1 H-NMR (CDCl 3 , ppm) δ6.09(s, 1H), 4.25(s, 1H), 1.38(s, 9H) 13 C-NMR (C 6 D. 6 , ppm) δ178.57 (q, CF 3 COCH), 116.52 (q, CF ...

Embodiment 3

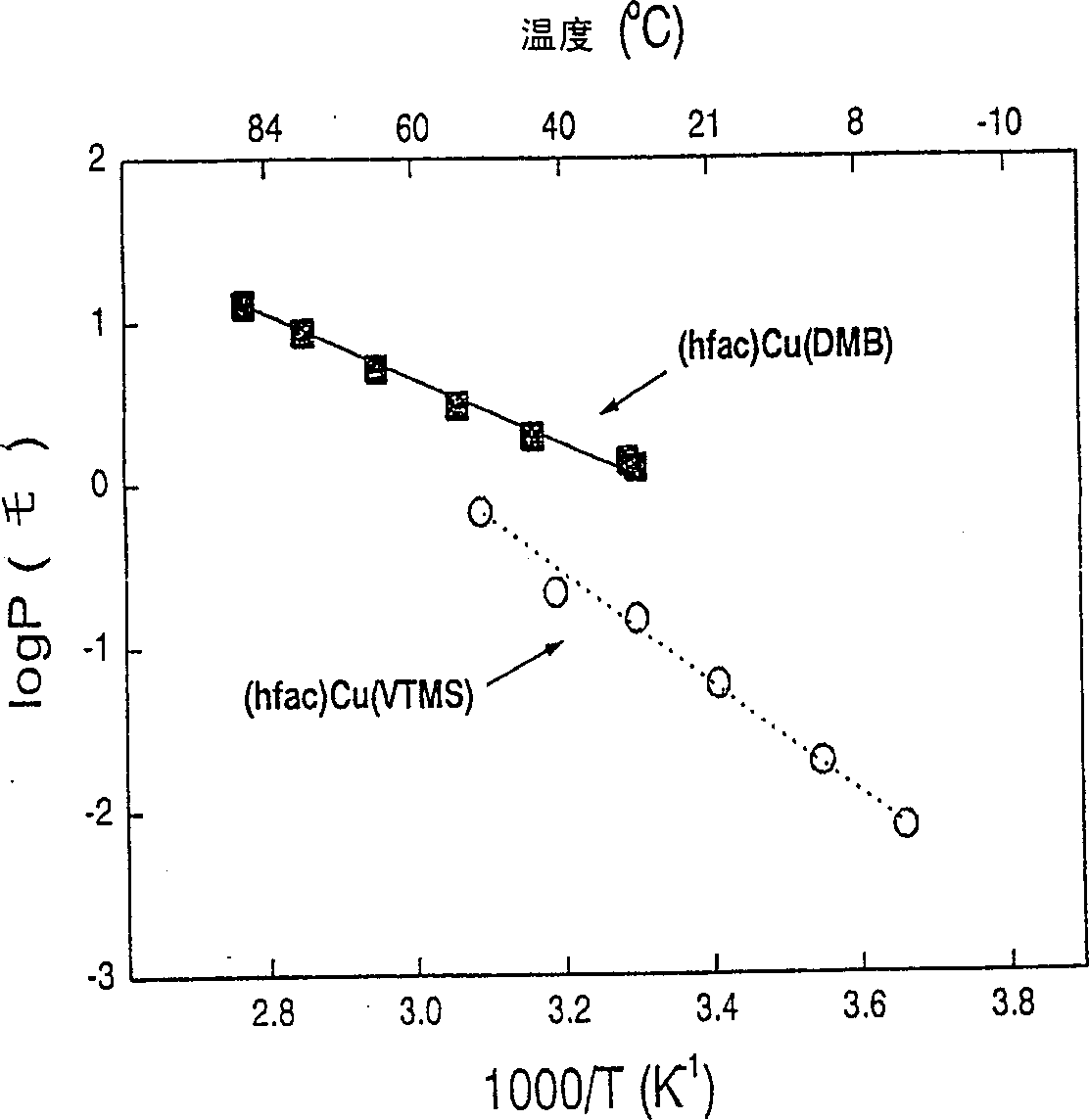

[0032] Embodiment 3: Deposit copper film on substrate

[0033] Using the precursors of the present invention synthesized in Example 1 and (hfac)Cu(VTMS) and (hfac)Cu(ATMS) as prior art precursors, coated with TiN or SiO by CVD method 2 Copper film was deposited on the substrate. Specifically, the compound was fed into a diffuser maintained at 45°C, and its vapor was delivered to the surface of the substrate in a CVD chamber set at a pressure of 0.3 mmHg in an argon gas flow at a flow rate of 50 sccm. The copper film deposition rate depending on the substrate temperature is shown in Figure 4 middle. Figure 4 The results demonstrated that the precursors of the present invention form copper films at a rate about 5-6 times faster than the prior art precursors.

[0034] On the other hand, the resistivity of films deposited using the precursors of the present invention depends on the temperature of the substrate, e.g. Figure 5 shown. available from Figure 5 It is seen that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com