Method and equipment for growing monocrystal of cadmium selenide by gas-phase vertical pulling

A vertical growth, cadmium selenide technology, applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve problems affecting crystal growth, low crystal resistivity, increased insecurity, etc., to reduce crystal growth Cost, simplified growth process, and the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

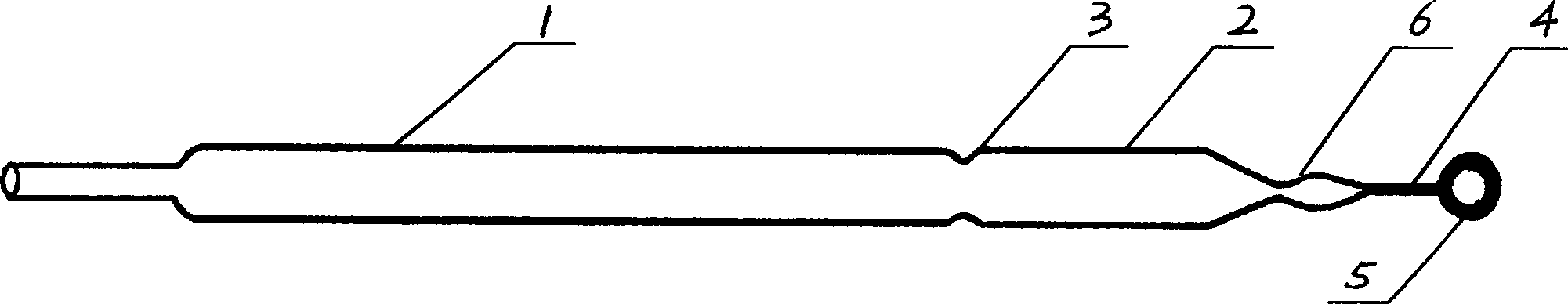

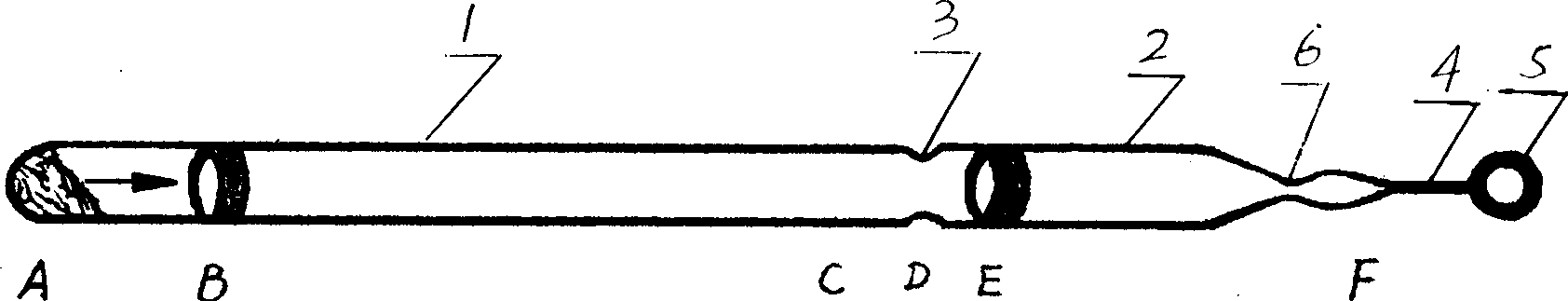

[0046] The present embodiment prepares the single crystal of cadmium selenide whose size is φ10×40 mm, and the ampoule used is as figure 2 As shown, it consists of a quartz tubular body of φ10 mm × 600 mm, a heat conducting rod 4 and a hanging ring 5. The tubular body is divided into a purification section 1 and a growth section 2 by a neck 3, and the length ratio of the purification section to the growth section is 3: 1. The end of the growth section is a closed structure and a cone. The cone angle of the conical end is 25°. The conical section is provided with a tube neck 6 to facilitate the geometric elimination of crystal nuclei to form single-nucleus growth.

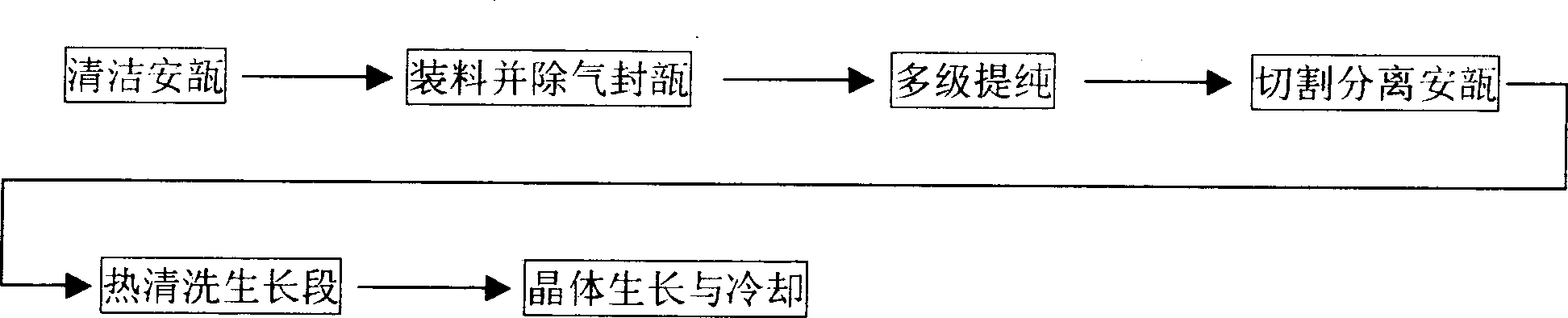

[0047] The technological process of this embodiment is as figure 1 As shown, the following steps are followed in sequence:

[0048] 1. Clean the ampoule

[0049] Cleaning ampoules adopts a combination of comprehensive cleaning and vacuum baking:

[0050] (1) Comprehensive cleaning

[0051]First soak and rinse t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com