Method for mfg. controllable structure inorganic nanoparticle/polymer composite superthin film

An inorganic nano- and ultra-thin film technology, which is applied in the field of preparation of inorganic nano-particles/polymer composite films, can solve the problems of poor compatibility between inorganic nanoparticles and organic polymer materials, harsh reaction conditions, and high energy consumption. The effects of uniform and controllable free radical polymerization, enhanced binding force and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

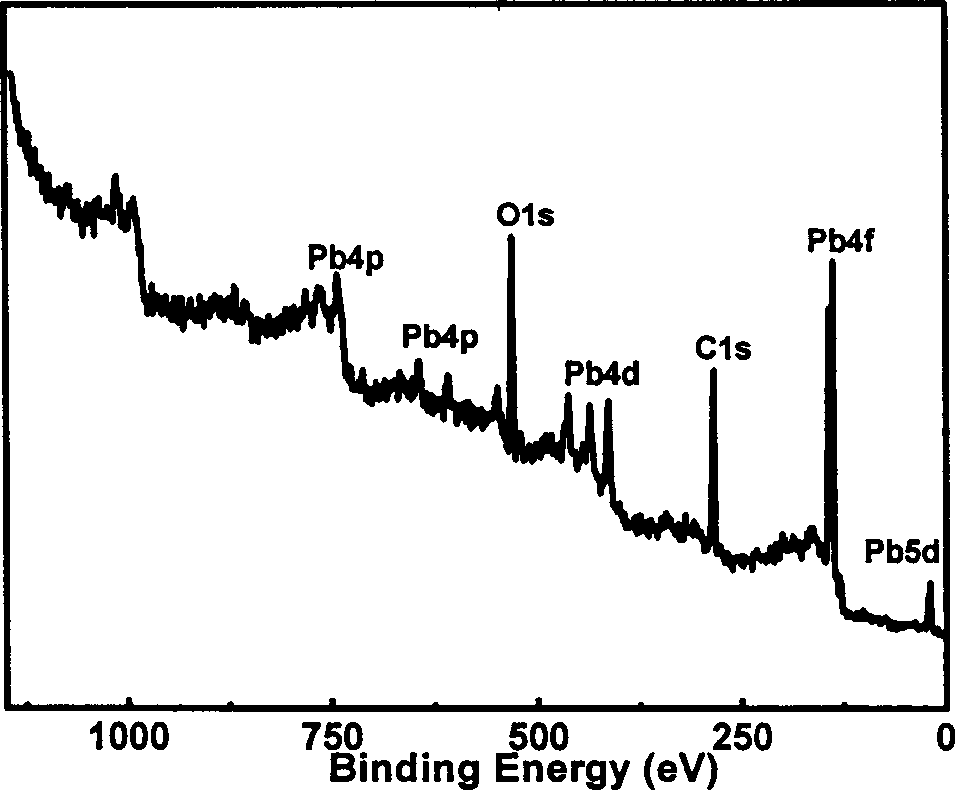

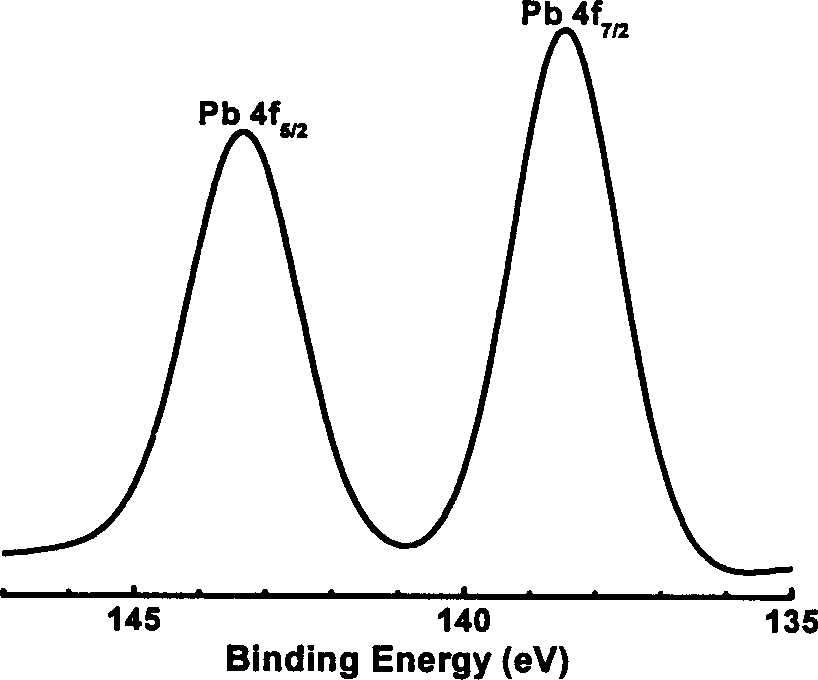

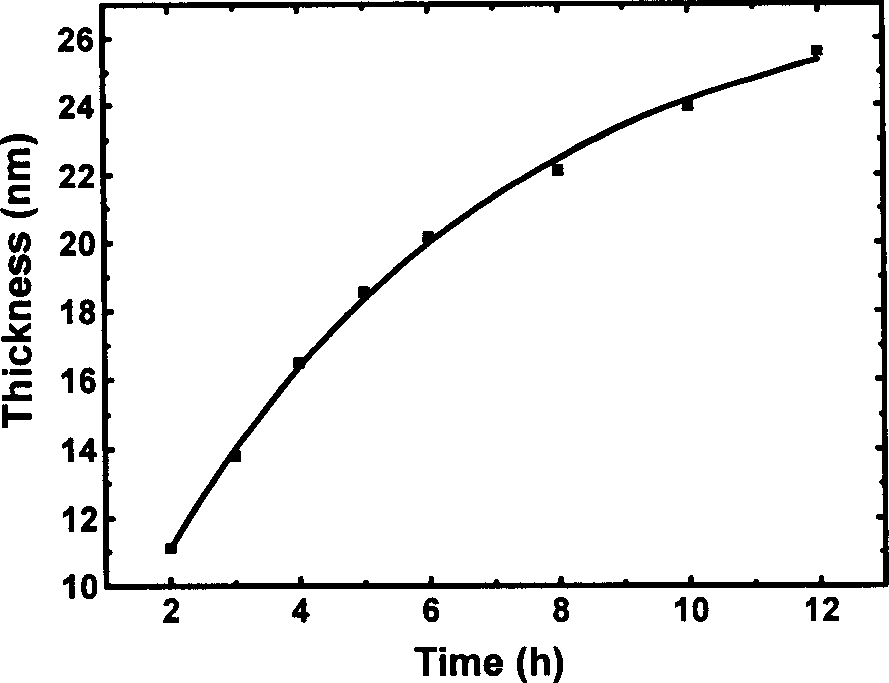

Image

Examples

Embodiment 1-2

[0030] Synthesis of α-zinc methacrylate

[0031] Add 89ml of α-methacrylic acid in 120ml of aqueous solution into a three-neck flask equipped with a reflux condensing device and a mechanical stirrer, and raise the temperature to 60°C. Then slowly add 40.7g of white zinc oxide into the three-necked flask to keep the reaction constant at 60°C, and stop the reaction after the white reactant is completely dissolved. Finally, the mixed solution was filtered while it was hot, and the excess acid and water were removed by rotary evaporation in the filtrate. After standing for 5 to 48 hours, pale yellow rod-shaped α-zinc methacrylate crystals were precipitated. The crystals were filtered out, washed, and vacuum-dried at room temperature.

Embodiment 1-3

[0033] Synthesis of α-cadmium methacrylate

[0034] Add 89ml of α-methacrylic acid in 90ml of aqueous solution into a three-neck flask equipped with a reflux condensing device and a mechanical stirrer, and raise the temperature to 65°C. Then slowly add 64.2g of black cadmium oxide into the three-necked flask to keep the reaction constant at 65°C, and stop the reaction after the black reactant is completely dissolved. Finally, filter the mixed solution while it is hot, remove excess acid and water by rotary evaporation, and after standing for 5 to 20 hours, a large number of white flaky cadmium methacrylate crystals precipitate out, filter out the crystals, wash, and vacuum dry at room temperature . Embodiment 1-4:

Embodiment 1-4

[0035] Synthesis of Europium α-Methacrylate

[0036]Add 60ml of α-methacrylic acid in 30ml of aqueous solution into a three-neck flask equipped with a reflux condensing device and a mechanical stirrer, and raise the temperature to 80°C. Then slowly add 5g of europium oxide into the three-neck flask to keep the reaction constant at 80°C, and stop the reaction after the white reactant is completely dissolved. Finally, the mixture was filtered while it was hot, and the filtrate was absorbed to neutrality with a large amount of 20ml of absolute ethanol, and finally the alcohol and water were removed by rotary evaporation, and after standing at 5°C for 5 to 20 hours, white flake Cadmium acrylate crystals were precipitated, and the crystals were filtered out, washed, and vacuum-dried at room temperature.

[0037] The synthesis of other organic acid salt-like metal monomers containing double bonds can be carried out by the same or similar method as in the examples, which will not be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com