Integration of continuous self-aligning semiconductor photoelectronic device and mode spot converter

A technology of mode spot converter and optoelectronic device, which is applied in the direction of semiconductor laser, semiconductor/solid-state device manufacturing, laser parts, etc., and can solve the problems of high crystal quality, large strain difference, and affecting the quality of growth materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: Polarization insensitive semiconductor optical amplifier SOA+SSC integration

[0034] The polarization insensitive semiconductor optical amplifier prepared by the present invention is integrated with SSC, and its preparation steps include as follows:

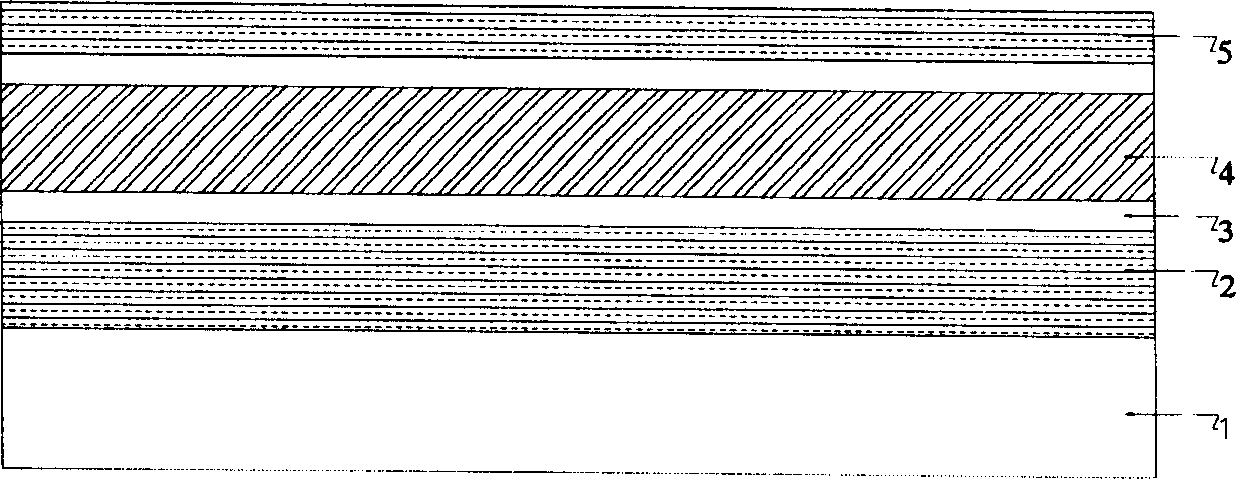

[0035] 1) On the n-type indium phosphorus (InP) substrate, the InP buffer layer, the indium gallium arsenide phosphorus (InGaAsP) lower waveguide layer, the InP lower isolation layer, the SOA active region, InP isolation layer and InGaAsP protection layer (such as figure 1 shown);

[0036] 2) corroding the InGaAsP protective layer on the top layer with a mixed solution of sulfuric acid, hydrogen peroxide and water;

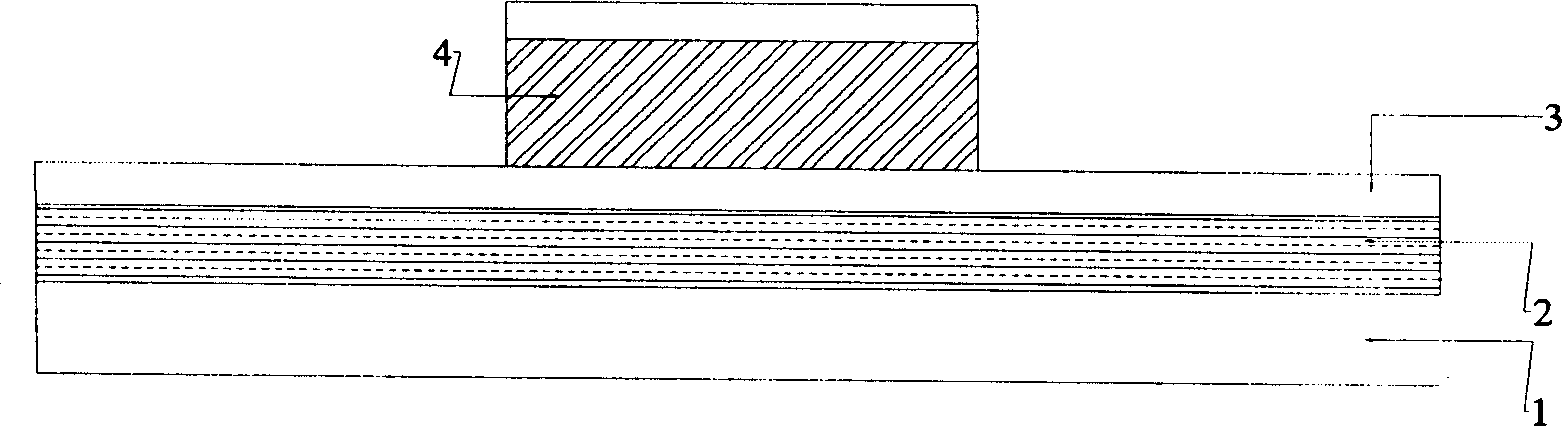

[0037] 3) Use ordinary photolithography etching technology to photoetch the SSC area until the InP lower isolation layer, such as figure 2 shown;

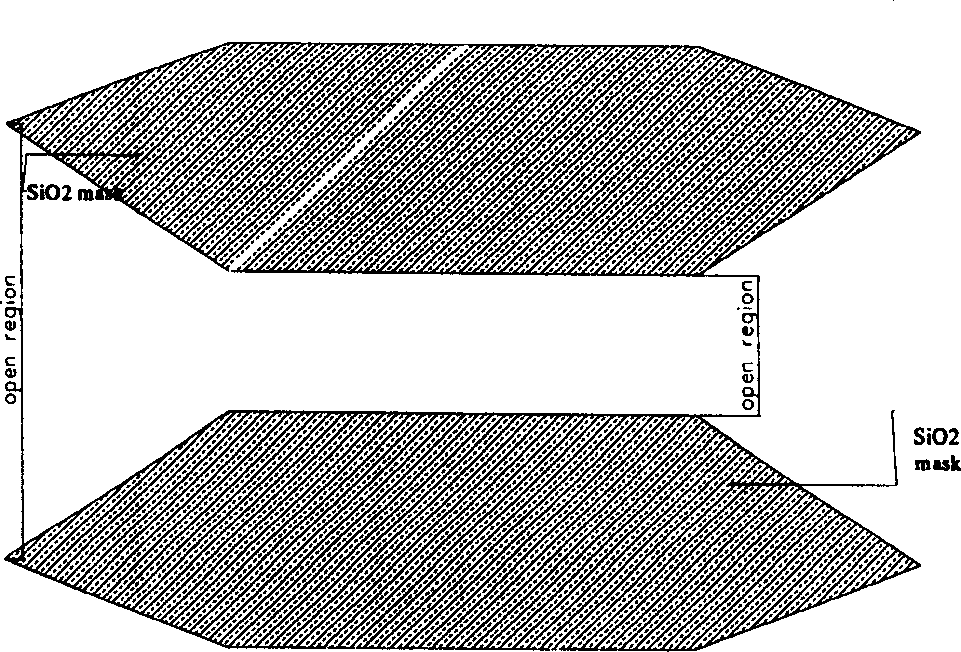

[0038] 4) Growth of SiO by plasma chemical deposition technology 2 150nm;

[0039] 5) Use such as image 3 Photolithographic plate, photolit...

Embodiment 2

[0049] The integration of electro-absorption modulator and SSC is exactly the same as that of special case 1, except that in the following process, according to the characteristics of electro-absorption modulator, a ridge waveguide structure needs to be used and the fabrication of electrodes needs to be filled with dielectric materials with low dielectric constant. And adopt pattern electrode. Embodiment Three: Integration of Distributed Feedback Laser (DFB) and SSC:

Embodiment 3

[0049] The integration of electro-absorption modulator and SSC is exactly the same as that of special case 1, except that in the following process, according to the characteristics of electro-absorption modulator, a ridge waveguide structure needs to be used and the fabrication of electrodes needs to be filled with dielectric materials with low dielectric constant. And adopt pattern electrode. Embodiment Three: Integration of Distributed Feedback Laser (DFB) and SSC:

[0050] The integration of DFB and SSC is almost the same as that of special case 1, except that DFB is a light-emitting device, so it only needs to be integrated with SSC at one end. After completing the selective growth SSC part, the following preparation steps must be used:

[0051]1) Etch the top layer InGaAsP and InP sequentially with a selective etching solution;

[0052] 2) Make a grating on the DFB part, as shown in Figure 6(a);

[0053] 3) Fully grow a p-InP cap layer and an InGaAsP protective layer o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com