Method for preparing secondary basic zinc electrode material

A zinc electrode, alkaline technology, applied in the field of preparation of secondary alkaline zinc electrode materials, can solve the problems of reducing the solubility of zinc electrode discharge products, unfavorable large-scale production, long reaction time, etc., and achieves good reversibility and stability Sexual, easy to grasp, short reaction time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

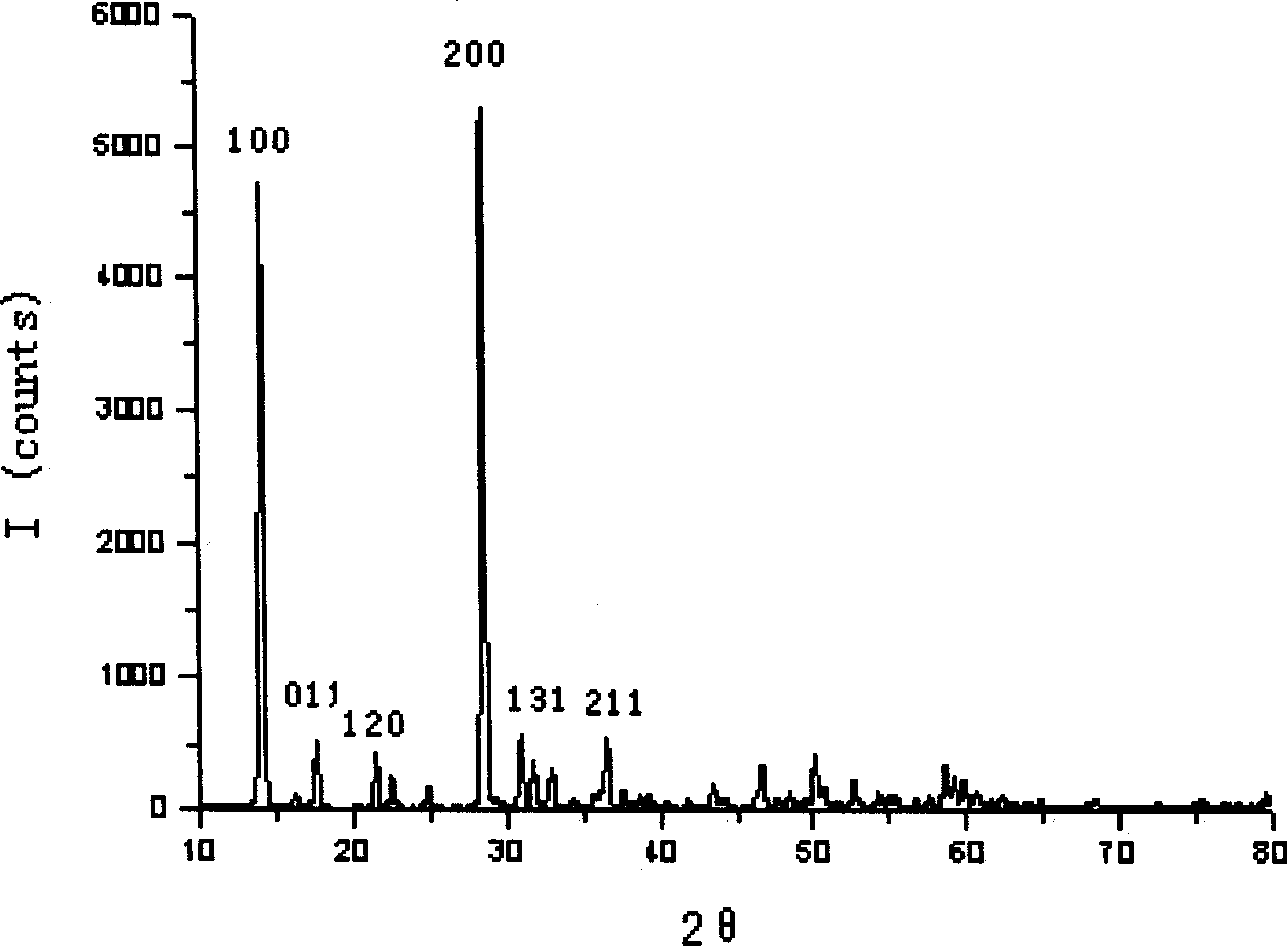

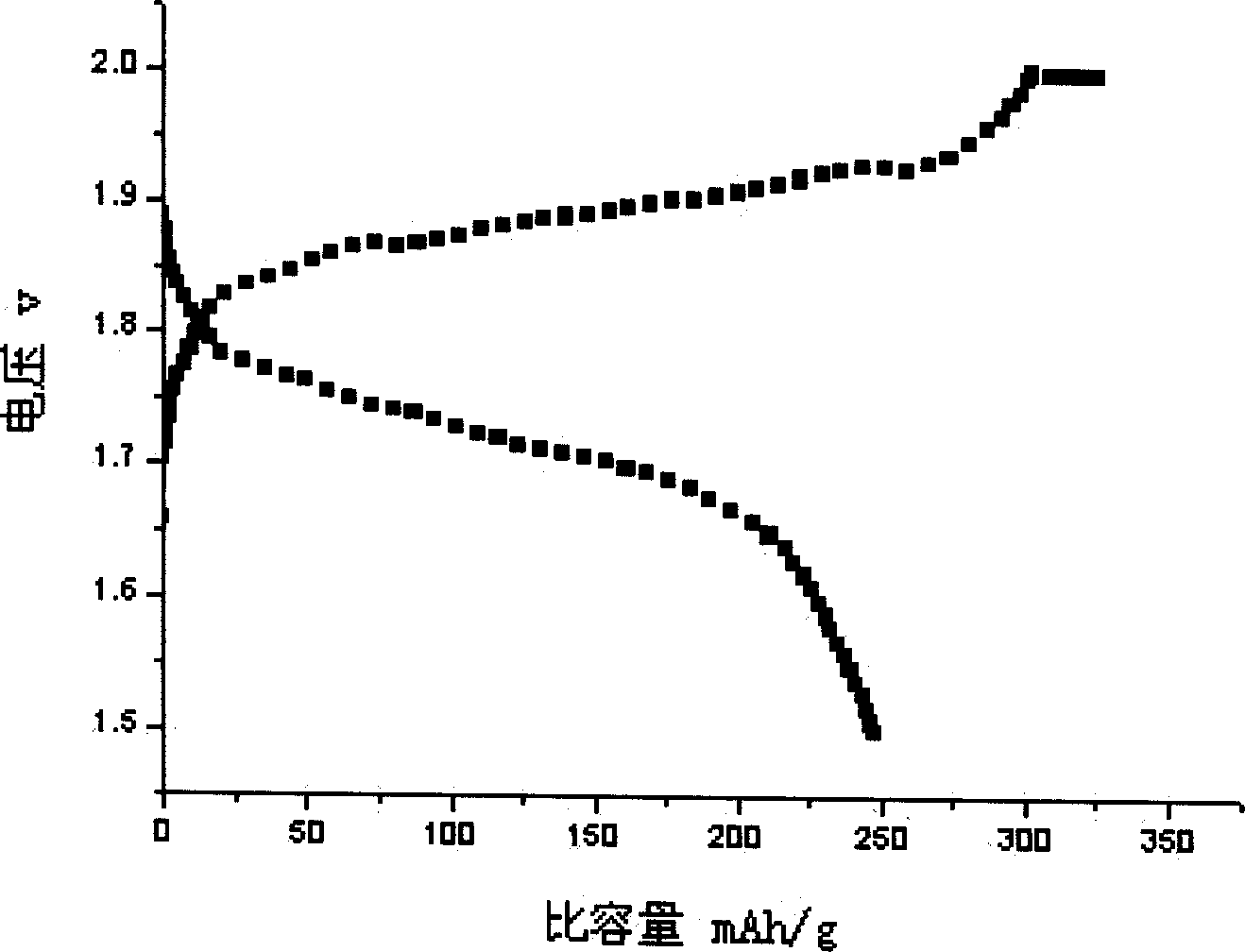

[0028] Accurately weigh 81.4g of ZnO, Ca(OH) 2 37.0g, H 2 0.300ml, add in the plastic reaction tank, put into 5 straight 20m and 20 agate balls with a diameter of 13mm, the reaction tank is placed on the rolling ball mill, at room temperature, the rolling ball milling reacted for 20 hours, then filtered, and deionized After washing with water and drying at 60°C for 24 hours, the desired secondary alkaline zinc electrode material can be obtained. From the X-ray powder diffraction pattern ( figure 1 ), and SEM images ( figure 2 ) It can be seen that the obtained secondary alkaline zinc electrode material has a monoclinic crystal structure. The charge-discharge curve of gained secondary alkaline zinc electrode material is as follows image 3 , Figure 4 As shown, it shows that after charging at 0.2C to 2.0V, charge at constant voltage for 30 minutes, and then discharge at 0.2C to 1.5V; after charging at 0.3C for 3 hours, discharge at 0.4C to 1.5V.

Embodiment 2

[0030] Accurately weigh ZnCl 2 68.2g, CaCl 2 27.7g, concentration is 420ml of potassium hydroxide aqueous solution of 20wt%, adds in the plastic reaction tank, puts into 6 agate balls that diameter is 25mm and 36 diameters are 9mm, and reaction tank is placed on rolling ball mill, under 30 ℃ , rolling ball milling reaction for 10 hours, then filtered and washed, and dried at 80°C for 20 hours to obtain the desired secondary alkaline zinc electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com