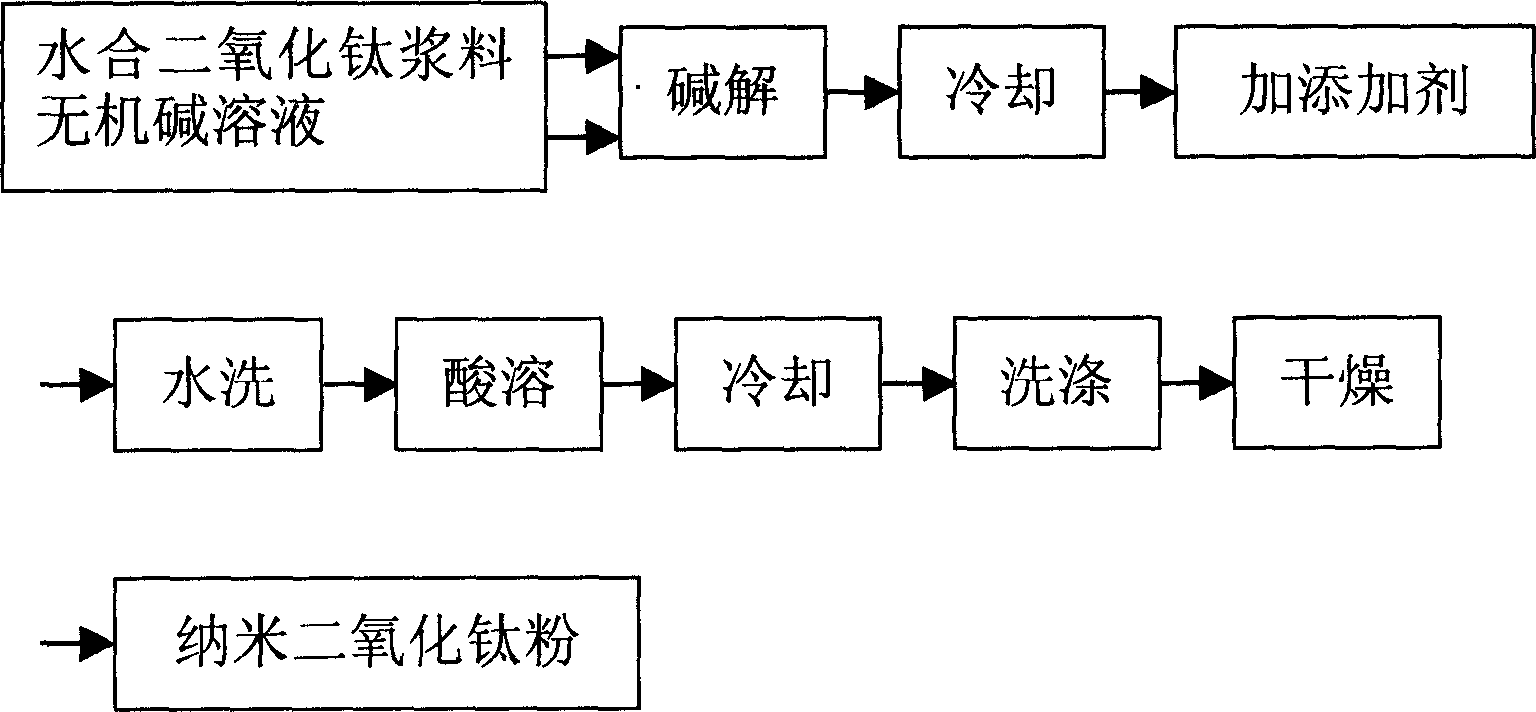

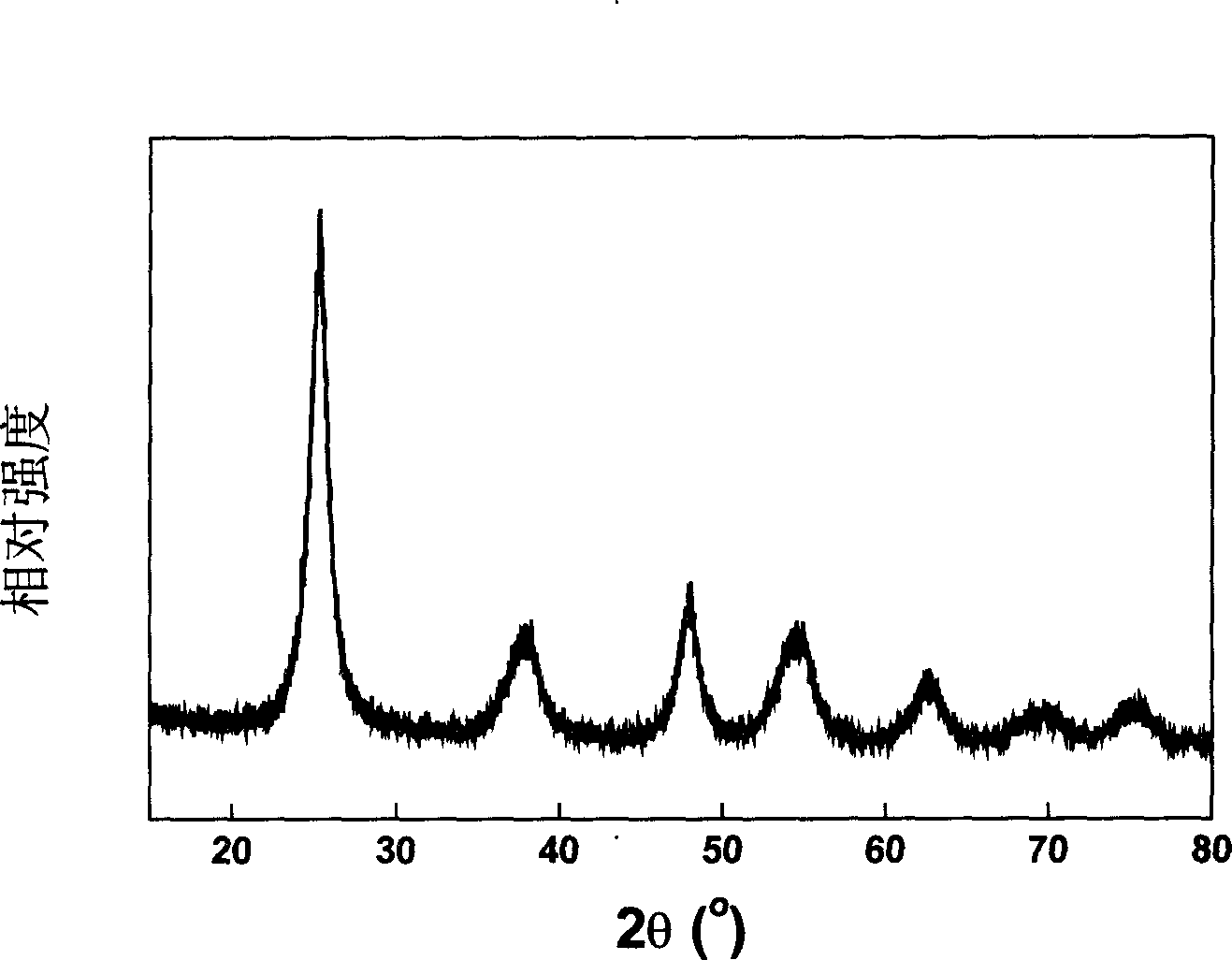

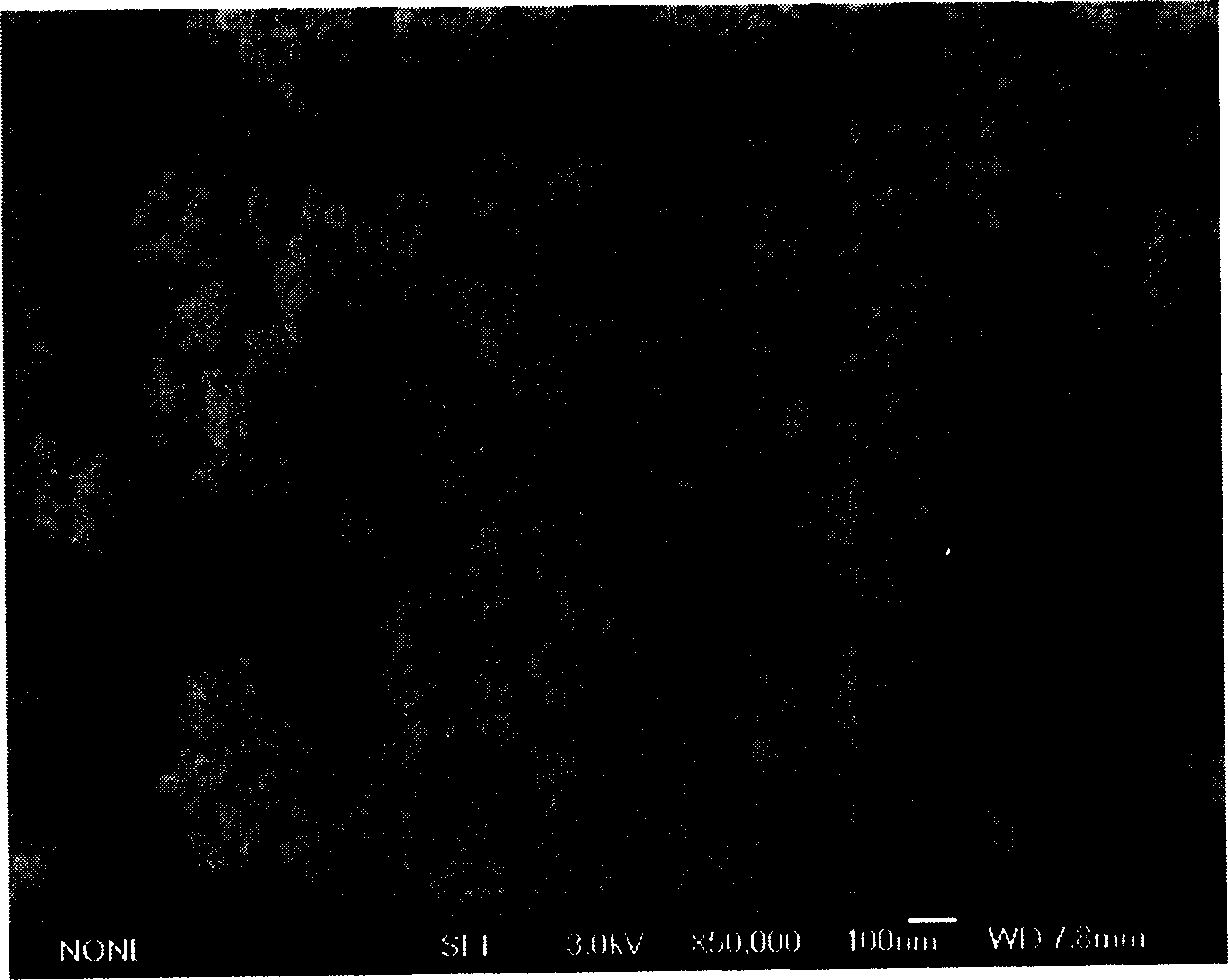

Low temperature preparing process for anatase phase nano crystal titanium dioxide of light catalystic activity

A technology of photocatalytic activity and titanium dioxide, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of high local concentration of materials, large investment, long reaction time, etc., and achieve strong surface adsorption capacity, high photocatalytic activity, and method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036](1) Alkaline hydrolysis: with a certain amount of deionized water, the washed 25Kg (125mol) hydrated titanium dioxide slurry (containing 40wt% TiO 2 ) is formulated into a uniform suspension containing 25wt% titanium dioxide; it is slowly injected into the reactor, and at a constant temperature of 65°C, 50wt% NaOH solution is added to it, the total addition of NaOH is 250mol, and the temperature is controlled at 80-90°C ( The dosing time is about 30 minutes), and continue to stir at constant temperature for 60 minutes to obtain a sodium orthotitanate solution; then rapidly cool the solution in the kettle to room temperature at a cooling rate of about 8°C / min; (2) Add a crystal nucleus accelerator: Add potassium sulfate with a titanium dioxide content of 2.0 wt%, and stir at a constant temperature; (3) Washing: add 4 times the volume of the original liquid to the reactor to dilute with deionized water, stir, settle for 10 hours, and remove the supernatant to obtain an amor...

Embodiment 2

[0041] (1) Alkaline hydrolysis: with a certain amount of deionized water, 12.5Kg hydrated titanium dioxide dry powder (containing TiO 2 80%) was prepared into a uniform suspension containing 25wt% of titanium dioxide, which was slowly injected into the reactor, and at a constant temperature of 65°C, a 40wt% KOH solution containing 250mol of KOH was added to it quickly and then slowly, and the temperature was controlled at 80- 90°C, continue to stir at a constant temperature for 80min to obtain a potassium orthotitanate solution; then rapidly cool the solution in the kettle to room temperature at a cooling rate of about 8°C / min; (2) Add a crystal nucleus promoter: add a titanium dioxide content of 3.0 wt% antimony trichloride, stirred at constant temperature for 40 minutes; (3) washing: add 4 times the volume of the original liquid to the reactor to dilute with deionized water, stir, settle for 10 hours, remove the supernatant, and obtain an amorphous white Precipitation; (4) ...

Embodiment 3

[0043] (1) Alkaline hydrolysis: with a certain amount of deionized water, the washed 25Kg (125mol) hydrated titanium dioxide slurry (containing 40wt% TiO 2 ) is formulated into a uniform suspension containing 30wt% of titanium dioxide; it is slowly injected into the reactor, and at a constant temperature of 60°C, Na 2 CO 3 260mol of 30wt% Na 2 CO 3 solution, the temperature is controlled at 80-90°C (dosing time is about 30min), and the constant temperature stirring is continued for 60min to obtain a sodium orthotitanate solution; then the temperature is lowered to room temperature; (2) Adding a crystal nucleus accelerator: adding titanium dioxide content 1.0wt% potassium sulfate, stirred at constant temperature for about 30min; (3) washing with water: adding 4 times the volume of the stock solution in deionized water to dilute the reaction kettle, after stirring for about 30min, settling for 8h, removing the supernatant to obtain Amorphous white precipitate; (4) acid solub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com