Method for preparing anode-support type yttrium oxide stable zirconium oxide electrolyte membrane

An anode-supported, stabilized zirconia technology, applied in zirconia, solid electrolyte fuel cells, fuel cell components, etc., can solve the problems of low film formation efficiency, shortened electrolyte membrane preparation cycle, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0007] Specific Embodiment 1: In this embodiment, the anode-supported yttria-stabilized zirconia electrolyte membrane is prepared in this way: (1), the porous anode support is prepared according to the traditional ceramic molding method; (2), YSZ is prepared on the surface of the anode support The electrolyte membrane, wherein the preparation of the electrolyte membrane on the surface of the anode support is carried out in the following steps: a, dissolving ethyl cellulose in terpineol to form ethyl cellulose terpineol with an ethyl cellulose content of 1 to 10% solution; b, after adding YSZ powder and antifoaming agent in ethylcellulose terpineol solution, grind more than 2h, obtain stable and uniform electrolyte slurry, wherein the weight ratio of YSZ and ethylcellulose terpineol solution is ( 1.5~4.0): 1, the amount of defoamer added is 0.1~10% of the total weight of the slurry; c, take the YSZ slurry prepared in step b, spread it evenly on the surface of the anode support, ...

specific Embodiment approach 2

[0008] Specific embodiment 2: This embodiment is to prepare anode-supported yttria-stabilized zirconia electrolyte membrane in this way: (1), prepare porous anode support body according to traditional ceramic molding method: YSZ, NiO and pore-forming agent are ground with The method is to mix it evenly, put it into a Ф13mm mold and press it into an anode diaphragm, put the diaphragm into a muffle furnace and sinter at 900-1400°C for 1-5 hours, remove the pore-forming agent, and form a porous anode support. After sintering, the pores of the anode The rate is 10-60%, wherein the weight ratio of NiO and YSZ is (1-4): 1; the pore-forming agent is starch or carbon powder, and its addition is 5-25% of the total weight of YSZ and NiO; Said that the average particle size of YSZ is 0.5-2.0 microns; (two), prepare YSZ electrolyte membrane on the surface of the anode support: a, fully dissolve ethylcellulose (ethylcellulose) in terpineol (terpineol) to form ethyl Terpineol solution of ce...

specific Embodiment approach 3

[0009] Specific embodiment three: In this embodiment, the anode-supported yttria-stabilized zirconia electrolyte membrane is prepared in this way:

[0010] 1. Preparation of porous anode support:

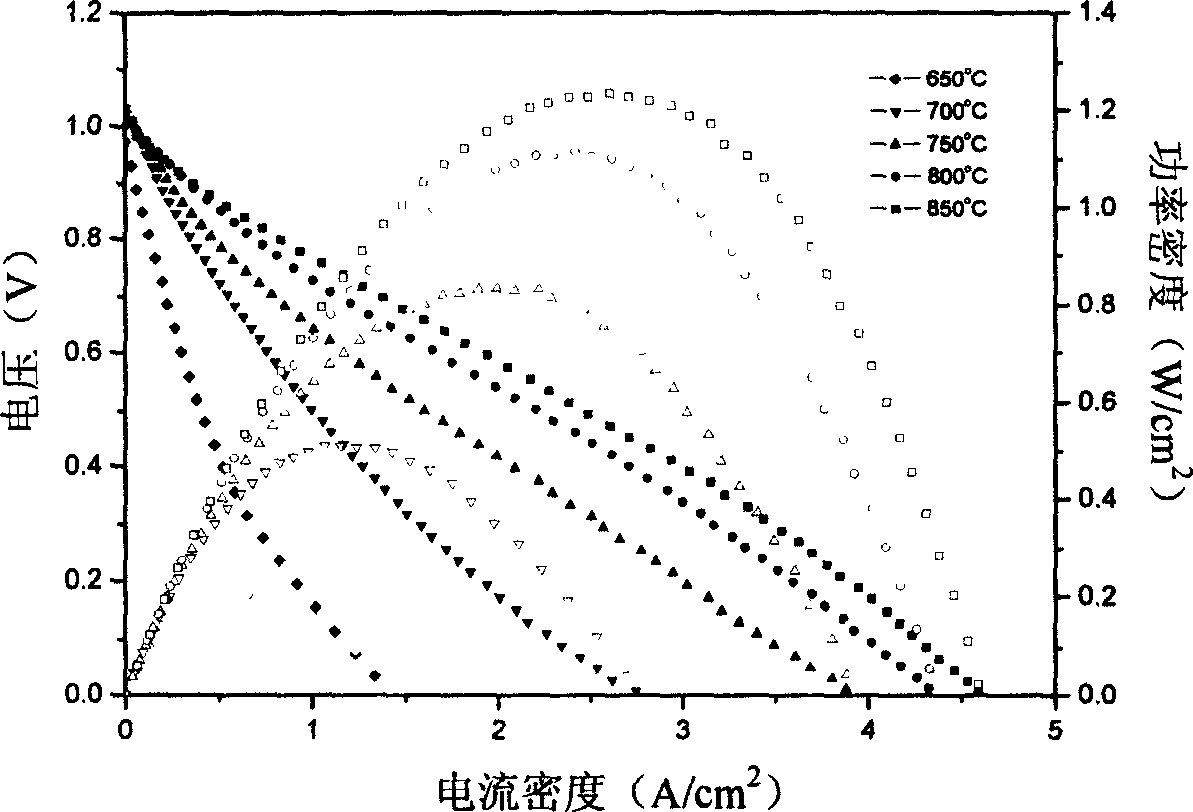

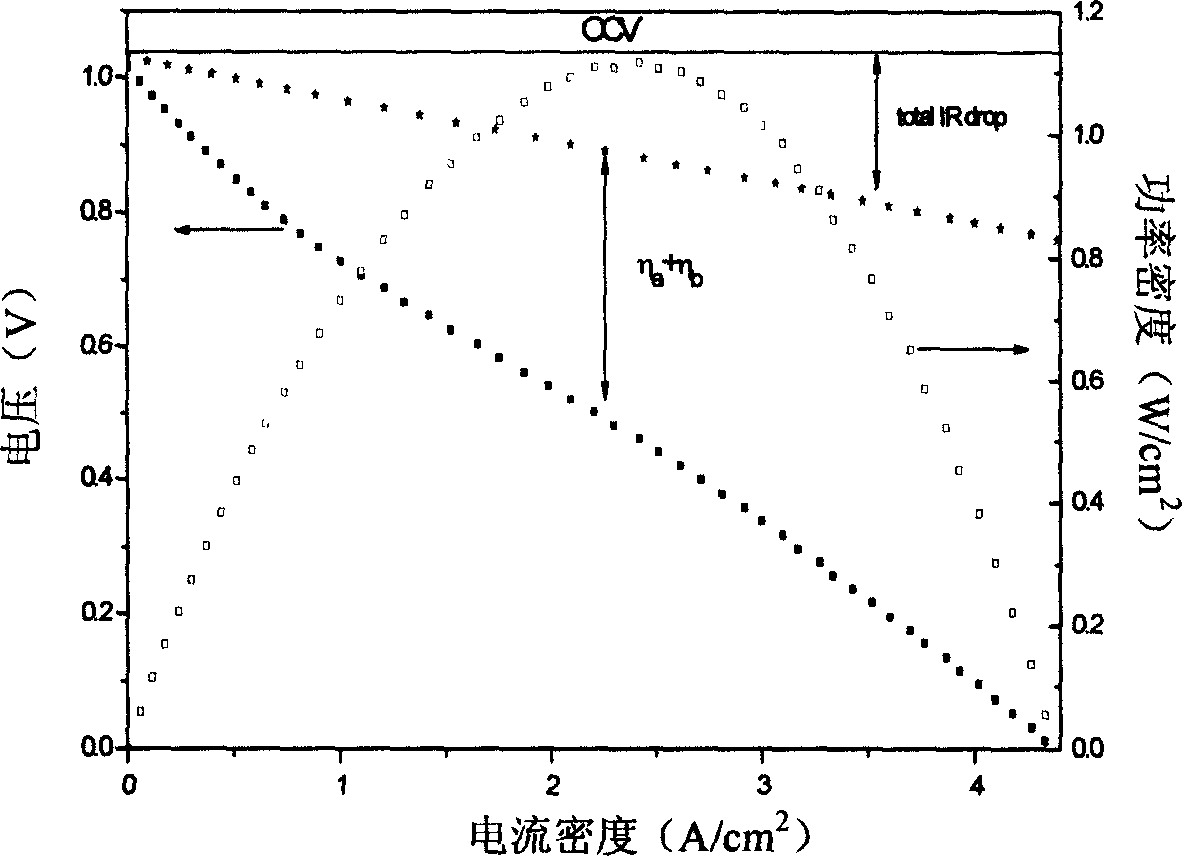

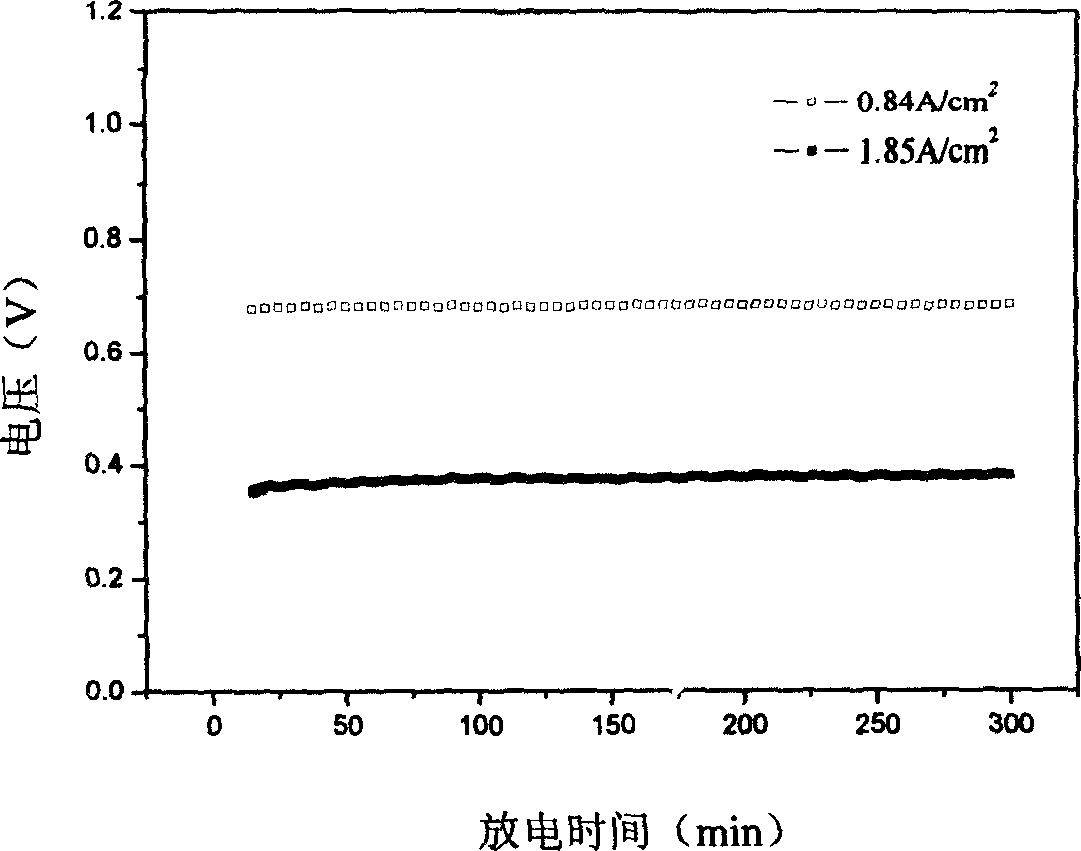

[0011] The porous anode support was prepared with commercial yttria-stabilized zirconia (YSZ) and self-made NiO by precipitation method (precipitation method), wherein YSZ contained yttrium oxide (Y 2 o 3 ) is incorporated in an amount (molar ratio) of 8%, and starch is added to the anode as a pore-forming agent. Take 2 grams of YSZ, 2 grams of NiO and 0.4 grams of starch, put them into an agate jar, add a large amount of absolute ethanol, and grind them with a planetary ball mill for 4-10 hours. After drying with an infrared lamp, take 0.2 grams and press them in a stainless steel mold with a pressure of 100-300 MPa. Form an anode sheet with a diameter of 13mm and a thickness of 0.4mm, sinter the anode sheet at 900-1400°C for 2 hours, remove the starch pore-forming agent, and obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com