Low-pressure metal organic chemical vapour phase depositing apparatus for zinc oxide and process thereof

A kind of equipment and zinc source technology, which is applied in the field of low-pressure metal-organic chemical vapor deposition equipment for zinc oxide growth and its technology, can solve the problems of poor growth quality of ZnO film, difficulties in p-type or high-resistance doping of ZnO materials, substrate , Samples and reaction chambers are susceptible to air pollution, etc., to achieve uniform heating and distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

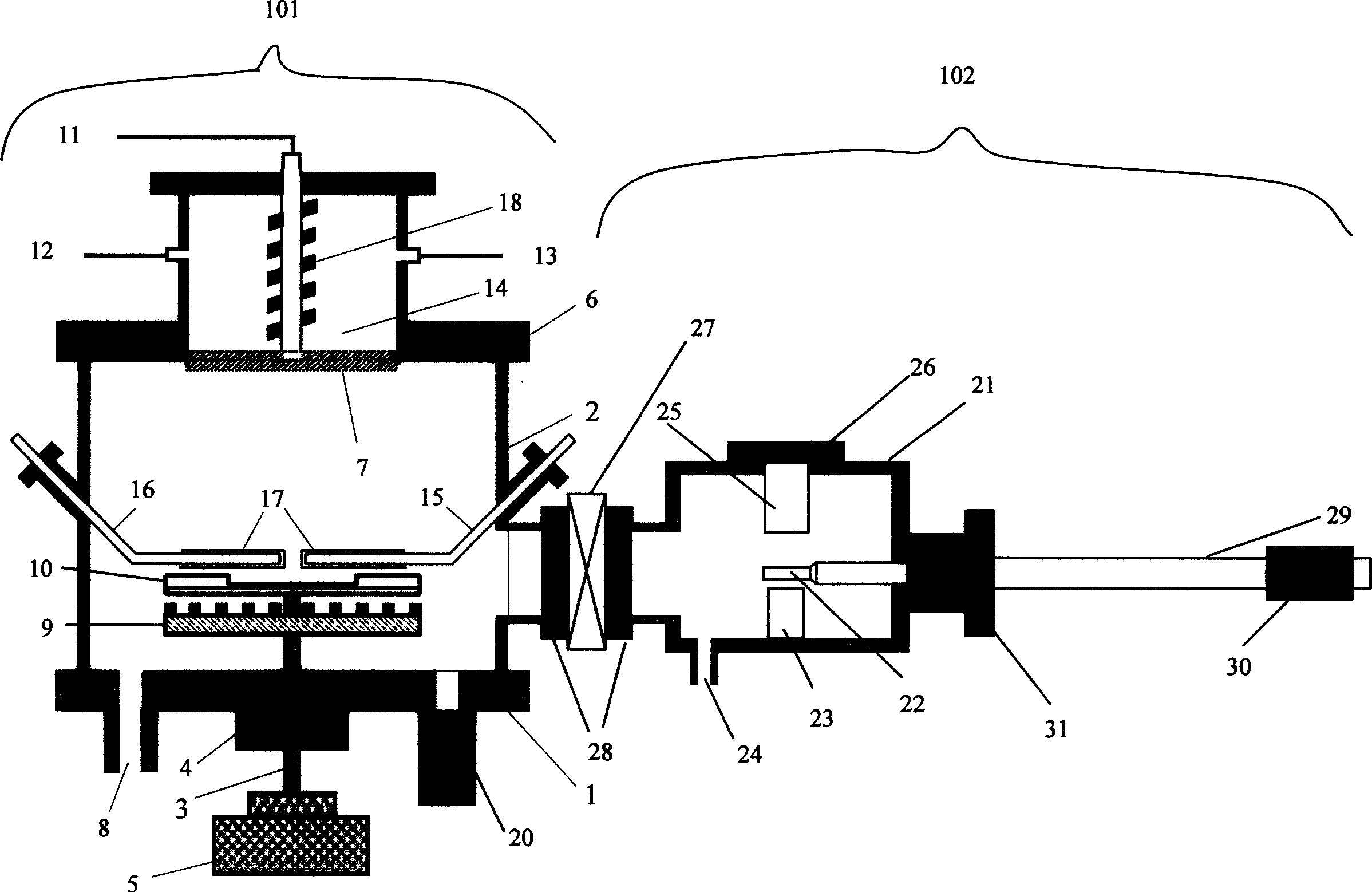

[0025] The technical features of the present invention will be further described below in conjunction with the ZnO thin film growth process.

[0026] The growth process of ZnO thin film is roughly as follows:

[0027] ①Put the substrate (sapphire, Si, GaAs or ZnO, etc.) on the sample tray rack (22) of the pretreatment chamber (102) after cleaning and etching, and then place the sample tray rack (22) with the sample on the On the sample stage (23), open the vacuum system of the sample pretreatment chamber (102) to evacuate the sample pretreatment chamber (102) through the pretreatment chamber air hole (24), when the vacuum degree reaches 10 -1 ~10 -3 During Pa, open plasma generator (25), carry out plasma cleaning 5~10 minutes to sample;

[0028] The steps of cleaning and etching the substrate are as follows: ultrasonic cleaning with toluene for 3 minutes, ultrasonic cleaning with acetone for 3 minutes, ultrasonic cleaning with ethanol for 3 minutes, and then recirculation on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com