Method for preparing mono dispersed functionalized polymer microsphere

A polymer, monodisperse technology, applied in the field of preparation of monodisperse functionalized polymer particles, can solve the problems of complex equipment, unfavorable industrial production, long time consumption, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

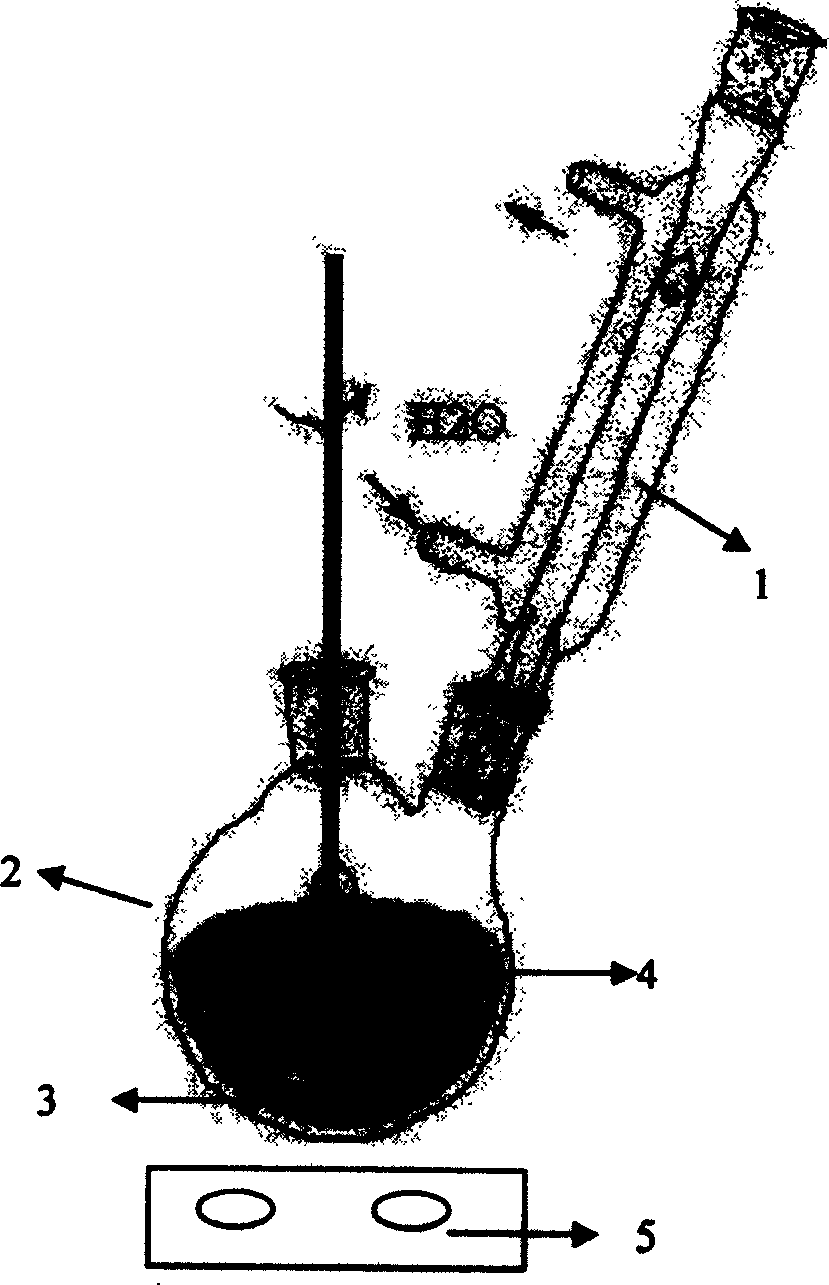

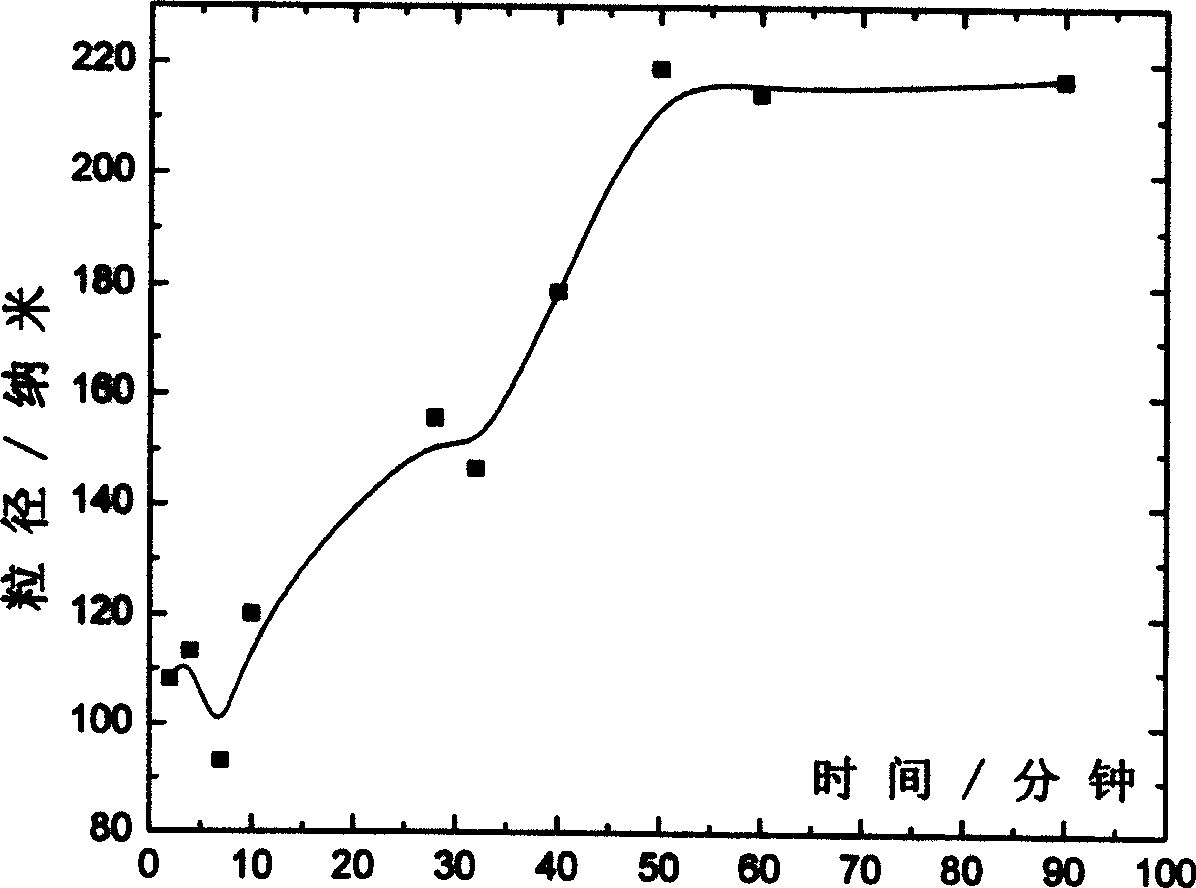

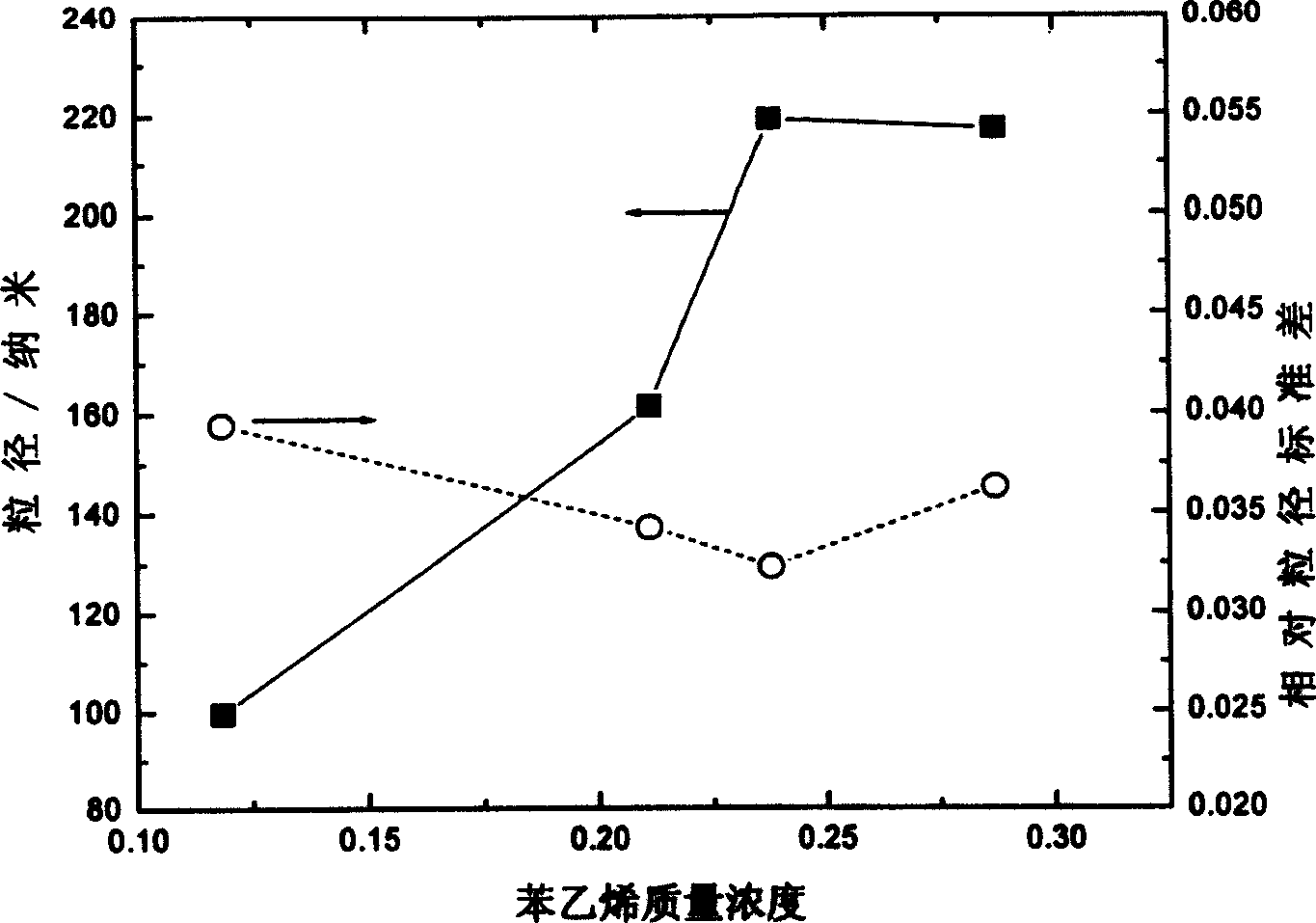

[0021] The preparation method of the monodisperse functionalized polymer microspheres of the present invention is as follows: vinyl monomers and water-soluble additives are first removed from the polymerization inhibitor by vacuum distillation, then added to a reaction kettle with a reflux condenser, and then Add water or water-alcohol azeotropic system, add persulfate initiator to start polymerization after 3-10 minutes after boiling, control monomer concentration between 5-20% and aqueous additive concentration between 0.5-2% , After 1.5 to 2 hours, monodisperse polymer particles can be obtained. The monomer is methacrylate, or acrylate, or styrene series, or vinyl ester, or oil-soluble propylene derivative, or vinyl chloride. The persulfate initiator used in the polymerization process is potassium persulfate or ammonium persulfate. The water-soluble additive as the functional group of the polymer is methacrylic acid, or acrylic acid, or acrolein, or water-soluble vinylic m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com