Planar inorganic device

An inorganic, planar technology that can be used in instruments, optical components, optomechanical equipment, etc., to solve difficult problems and achieve the effect of maintaining speed, optimization of mechanical and dielectric properties, and ease of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

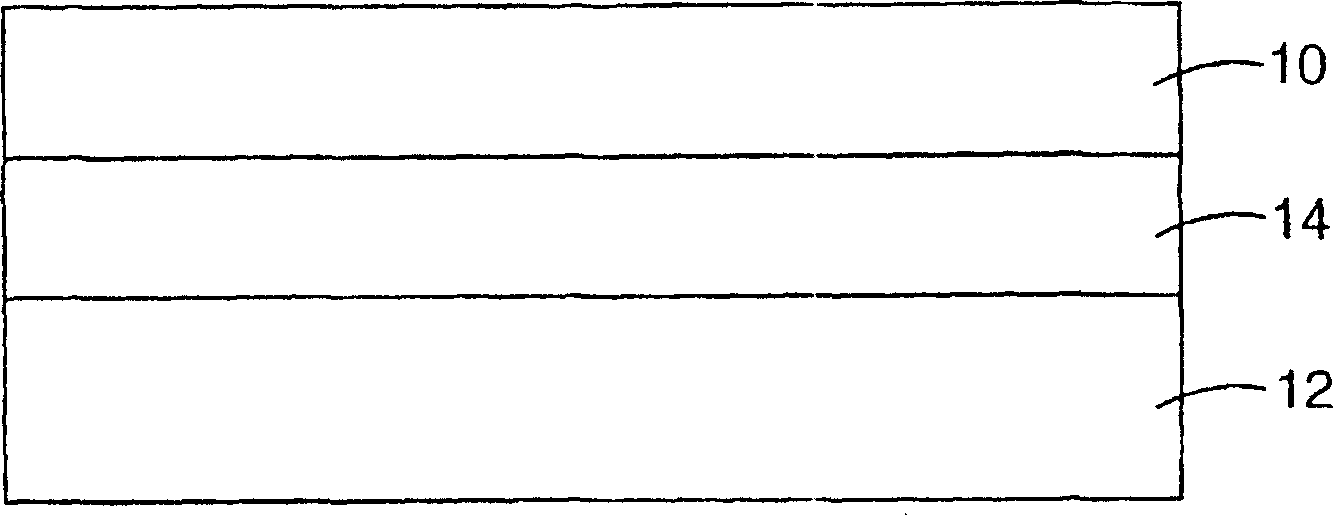

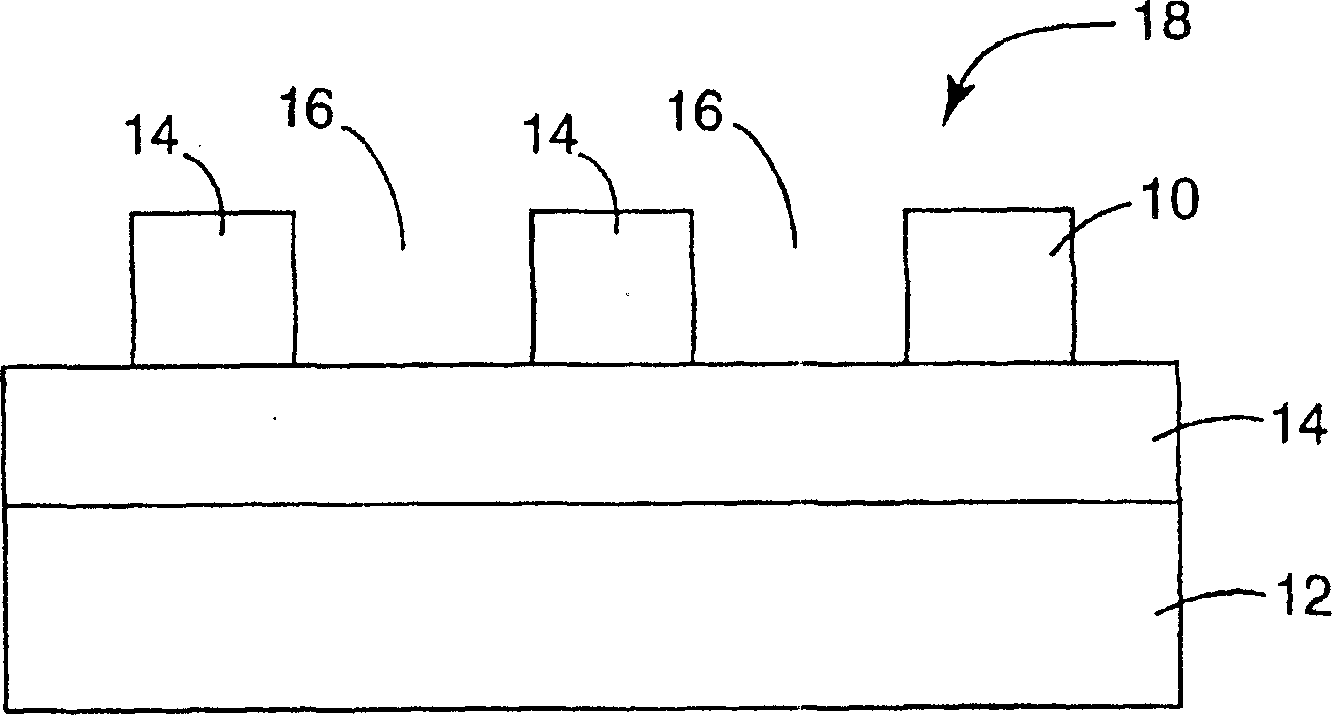

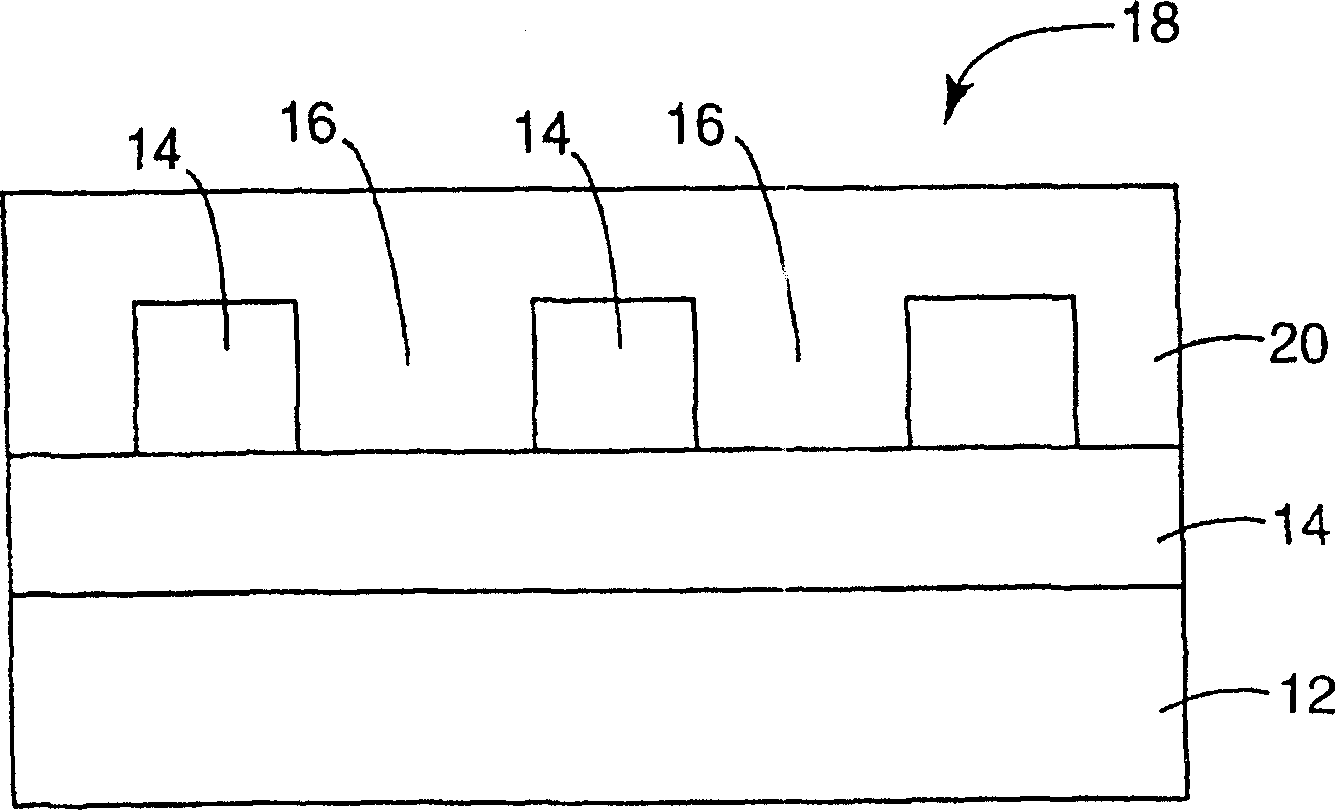

Image

Examples

preparation Embodiment 1

[0194] The sensitizing dye, bis-[4-(diphenylamino)styryl]-1-(2-ethylhexyloxy), 4-(methoxy)benzene, was prepared as follows:

[0195]

[0196]

[0197] 1-methoxy-4-(2-ethylhexyloxy)benzene (1)

[0198] A mixture of 4-methoxyphenol (100.0 g, 0.8 mol), dry potassium carbonate (166.7 g, 1.2 mol), acetonitrile (800 mL) and 2-ethylhexyl bromide (173.8 g, 0.9 mol) was mechanically stirred, and Reflux for 4 days. After cooling, the mixture was diluted with water (1.5 L) and the organic phase was separated. The aqueous layer was extracted with hexane, and the combined organic layers were washed with 1.0 mol / L NaOH and water. with MgSO 4 After drying, the solvent was removed under reduced pressure to yield an orange oil. The crude product was distilled under reduced pressure to yield 152 g (80%) of a clear oil (bp 135-138°C at 0.4 mm Hg).

[0199] 2,5-bis(bromomethyl)-1-methoxy-4-(2-ethylhexyloxy)benzene (2)

[0200] 1-Methoxy-4-(2-ethylhexyloxy)benzene (50.0 g, 0.21 mol), p...

preparation Embodiment 2

[0206] The preparation method of the silica-epoxy resin sol containing the colloidal silica of various particle diameters is demonstrated.

[0207] Formula A

[0208] 245 grams of NALCO 2327 solution (a 41% aqueous dispersion of silica with a particle size of approximately 20 nm obtained from Ondeo Nalco, Bedord Park, IL) was placed in a round bottom flask with moderate agitation. A premixed solution of 500 grams of 1-methoxy-2-propanol and 12.34 grams of trimethoxyphenylsilane (0.62 millimoles of silane per gram of silica) was added over a period of 5-10 minutes. The resulting non-aggregated solution was heated at 90-95°C for about 22 hours, and dried to form a white powder. The treated silica (100 grams of silica in 300 grams of water) was added to deionized water, vigorously stirred for 3-4 hours, and then allowed to stand overnight at room temperature. Silica was filtered, rinsed several times with deionized water and dried.

[0209] The treated silica was dispersed in ...

Embodiment 3

[0226] This example illustrates the photopatterning of a silica-epoxy sol containing 20 nm colloidal silica. Silicon wafers were cleaned by immersing in a 3:1 mixture of sulfuric acid (98% in water) and hydrogen peroxide (30% in water) for 10 minutes, rinsed thoroughly with deionized water, rinsed with isopropanol and dried. To improve the adhesion of the resin to the substrate, the wafer is treated with an epoxy-silane coupling agent. 2 wt % 2-(3,4 epoxycyclohexyl)-ethyltrimethoxysilane (Gelest, Tullytown, PA) in slightly acidic (pH 4-5) aqueous ethanol (Aper, Shelbyville, KY) was prepared solution. The wafers were dip-coated in this solution for about 60 seconds and rinsed briefly with absolute ethanol (EM Science, Gibbstown, NJ). The primed wafers were allowed to cure overnight. Work under safe light conditions, based on the resin solid weight, 0.6% of two-[4-(diphenylamino) styryl]-1-(2-ethylhexyloxy), 4-( A photoinitiator system consisting of methoxy)benzene (from Exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com