Method of electrodynamics for restoring soil polluted by heavy metal

A technology of polluted soil and electrokinetics, applied in electrokinetic remediation, using ion exchange membranes to assist electrokinetics in the field of remediation of polluted soils, can solve the negative impact on the safety of soil ecosystems, the limited adsorption capacity of carbonate adsorption layers, and limited popularization and application and other problems, to achieve the effect of increasing migration speed, convenient operation, and improving removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

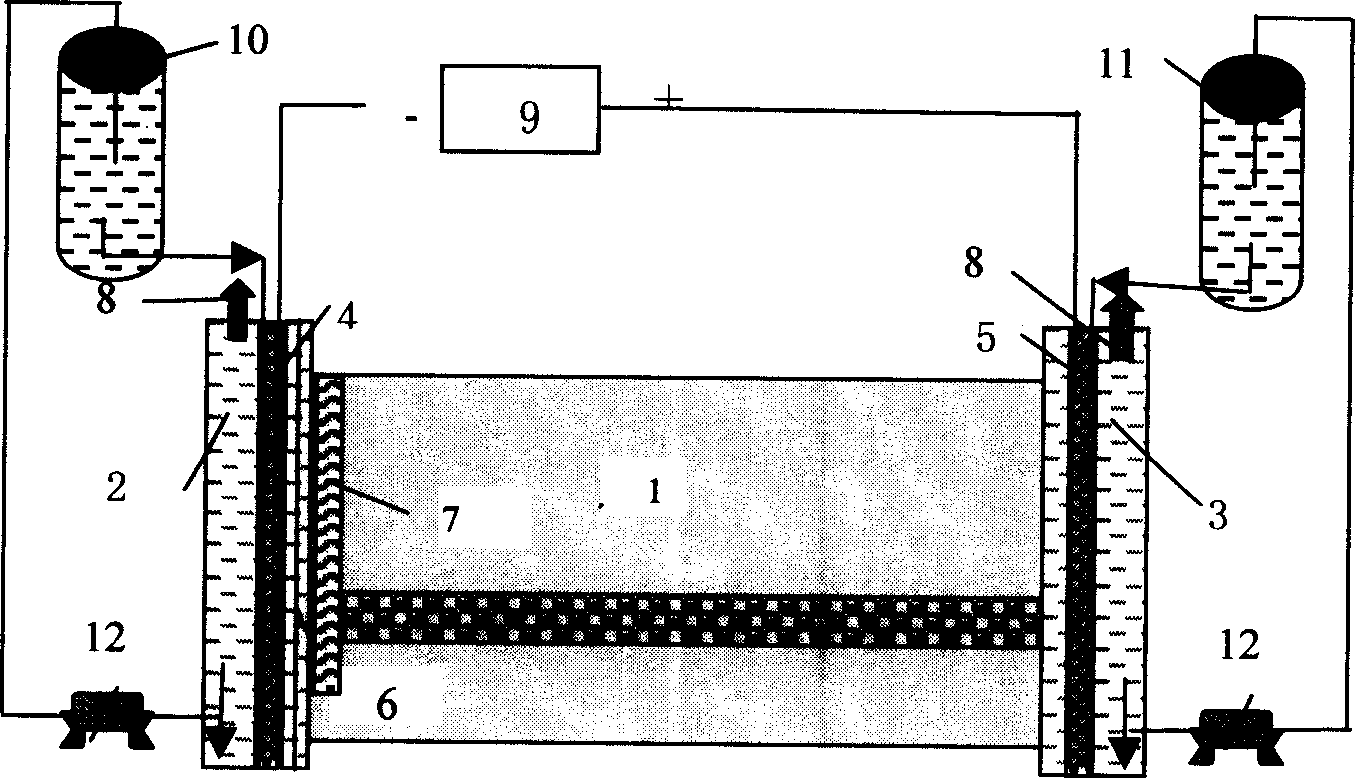

[0022] Embodiment 1 adopts such as figure 1 The shown device performs soil electrokinetic remediation treatment. The electrolytic cell 1 is an open container and placed horizontally. The cathode chamber 2 and the anode chamber 3 are respectively arranged at both ends of the electrolytic cell 1 . The cathode 4 is placed in the cathode chamber 2 and the anode 5 is placed in the anode chamber 3 . The cation exchange membrane 6 is placed between the cathode chamber 2 and the electrolytic cell 1 , and the porous ceramic plate 7 is placed between the ion exchange membrane 6 and the soil in the electrolytic cell 1 . The positive pole of the stabilized DC power supply 9 is connected to the anode 5 through wires, and the negative pole is connected to the cathode 4 . The catholyte buffer tank 10 and the anolyte buffer tank 11 communicate with the cathode chamber 2 and the anode chamber 3 respectively through the engineering plastic pipe delivery pump 12 . The ratio of the volume of th...

Embodiment 2

[0025] The structure of the repairing device adopted is the same as in Example 1, and the ratio of the volume of the cathode chamber and the anode chamber to the volume of the electrolytic cell is 1:20. Weigh about 1000g simulated polluted soil sample, in which the cadmium concentration is about 100mg / kg, and use PbO 2 The / Ti electrode is the anode, and the graphite is the cathode; the cathode chamber and the soil sample are separated by a sulfonic acid type homogeneous cation exchange membrane, and the hourly circulation flow rate of the electrolysis buffer to the corresponding electrode chamber volume volume ratio is 0.01. The electrolysis buffer uses oxalic acid-sodium oxalate buffer solution with 2.5mol / l and pH value of 4; the constant voltage is 2V, the corresponding electric field strength is 0.2V / cm; It shows that the cadmium content in the soil sample is reduced to 0.50mg / kg. After the test, white Cd(OH) with a purity of 80.6% was separated in the cathode chamber 2...

Embodiment 3

[0027]The structure of the repairing device adopted is the same as in Example 1, and the ratio of the volume of the cathode chamber and the anode chamber to the volume of the electrolytic cell is 1:10. The simulated polluted soil with a lead content of about 100mg / kg was treated, and graphite electrodes were used as electrodes; the cathode chamber was separated from the soil sample by a sulfonic acid type homogeneous cation exchange membrane; The chamber volume to volume ratio was 0.2. The electrolytic buffer solution is acetic acid-sodium acetate buffer solution with 0.5mol / l and pH value of 3; the constant voltage is 15V, and the corresponding electric field strength is 1.5V / cm; It shows that the lead content in the soil sample is reduced to 0.46mg / kg. Qualitative analysis of the sediment in the cathode chamber shows that its main component is lead hydroxide, and Pb(OH) 2 Has very low solubility (dissolution constant is 1.2×10 -15 ) to obtain Pb(OH) with a purity of 85% b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com