Method for bonding two solid plane by surface atom transition free radical aggregation

A technology of atom transfer and free radicals, which is applied in the direction of pattern surface photolithography, precision positioning equipment, microstructure technology, etc., can solve problems such as analysis interference, analysis system pollution, and unsuitability for mass production of chips.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

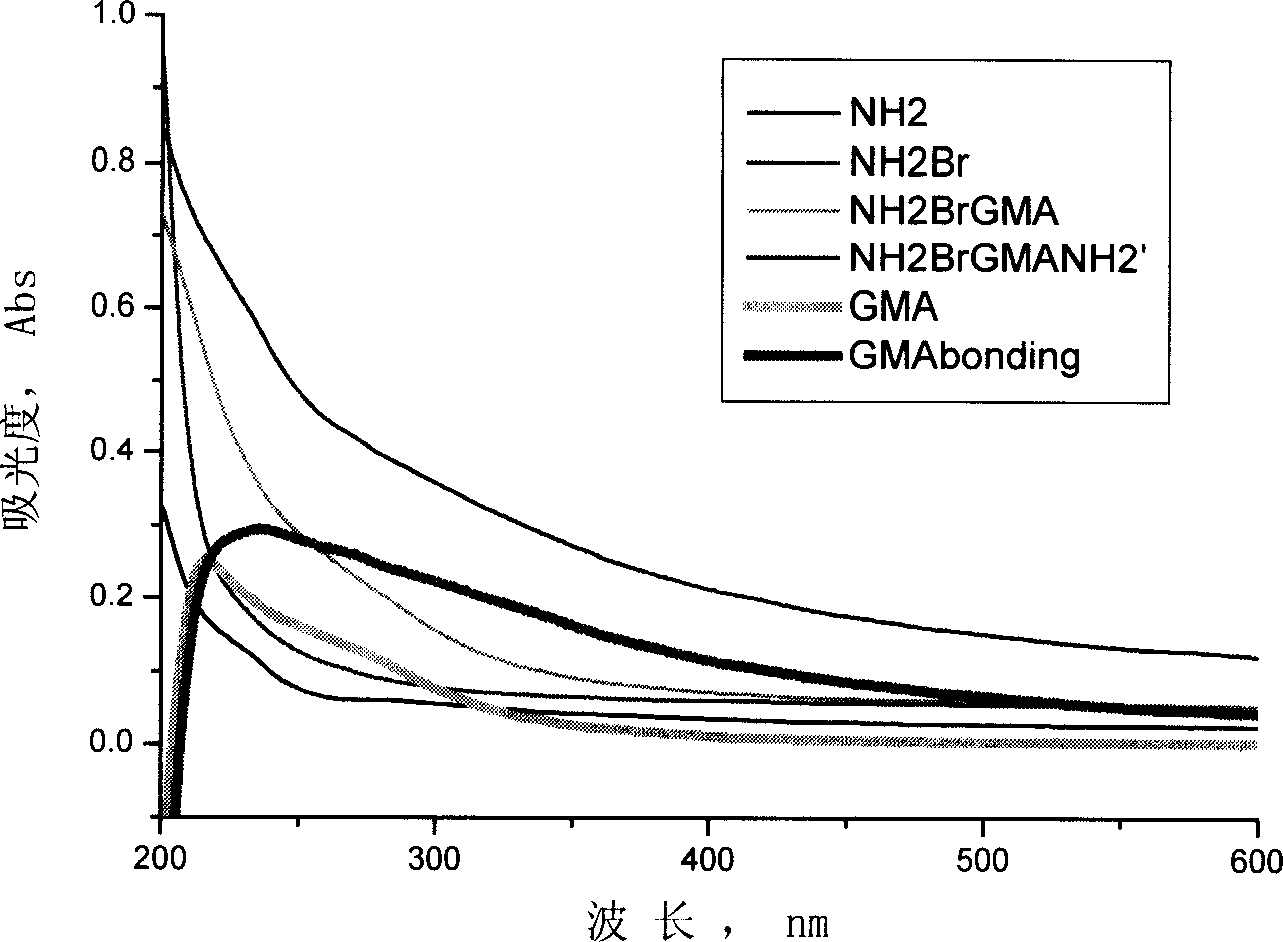

[0040] Example 1: Glycidyl methacrylate (GMA) is used to carry out atom transfer radical polymerization to assemble a membrane base and an aminated base for bonding.

[0041] The first step: cleaning and hydroxylation of film base

[0042] [American Chemical Society, Langmuir, 1996, 12, 4621-4624; Joong Ho Moon, Ji Won Shin, Formaion of Uniform Aminosilane Thin Layers: An Imine Formaion To Measure Relative Surface Density of the AmineGroup., Langmuir 1996, 12, 4621 -4624】

[0043] The glass, quartz or silicon substrate whose surface layer is pre-oxidized to silicon oxide is first washed with deionized water in an ultrasonic instrument for 5 minutes, then ultrasonically washed in an ethanol (95%) solution at 30°C for 5 minutes, and then washed with dichloro After sonicating with methane for 5 min, wash with NH 3 (25%): H 2 o 2 (30%): H 2 The mixed solution of O=1:1:5 (V / V / V) was ultrasonically washed at 70°C for 30 minutes, washed with a large amount of deionized water unt...

Embodiment 2

[0052] Example 2: Glycidyl acrylate is used to carry out atom transfer radical polymerization to assemble a membrane base and aminated base for bonding.

[0053] The first step: cleaning and hydroxylation of film base and

[0054] Second step: the amination of the hydroxylated film base is the same as in Example 1;

[0055] The third step: assembling an initiator for atom transfer radical polymerization on the surface of the aminated sheet;

[0056] Put the aminated base into a 25cm long thin tube, bake the bottle three times, add 40ml of dichloromethane after cooling, slowly add 1ml of 2-bromo-2-methylpropionyl bromide under the condition of stirring at room temperature and nitrogen protection , then add 1ml of pyridine dropwise, react at room temperature for 10 hours, take out the film base, wash it ultrasonically for 3 times with dichloromethane, then pump it to dryness under reduced pressure, store it under nitrogen, and use it for the next reaction;

[0057] The fourth ...

Embodiment 3

[0061] Example 3: Glycidyl methacrylate (GMA) body was used to carry out atom transfer radical polymerization to assemble the membrane base and the aminated base for bonding.

[0062] The first step: cleaning and hydroxylation of film base and

[0063] Second step: the amination of the hydroxylated film base is the same as in Example 1;

[0064] The third step: assembling an initiator for atom transfer radical polymerization on the surface of the aminated sheet;

[0065] Put the aminated base into a 25cm long thin tube, bake the bottle three times, add 40ml of dichloromethane after cooling, slowly add 1ml of 2-bromo-2-methylpropionyl bromide under the condition of stirring at room temperature and nitrogen protection , then add 1ml of pyridine dropwise, react at room temperature for 8 hours, take out the film base, wash it ultrasonically for 3 times with dichloromethane, then pump it to dryness under reduced pressure, store it under nitrogen, and use it for the next reaction; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com