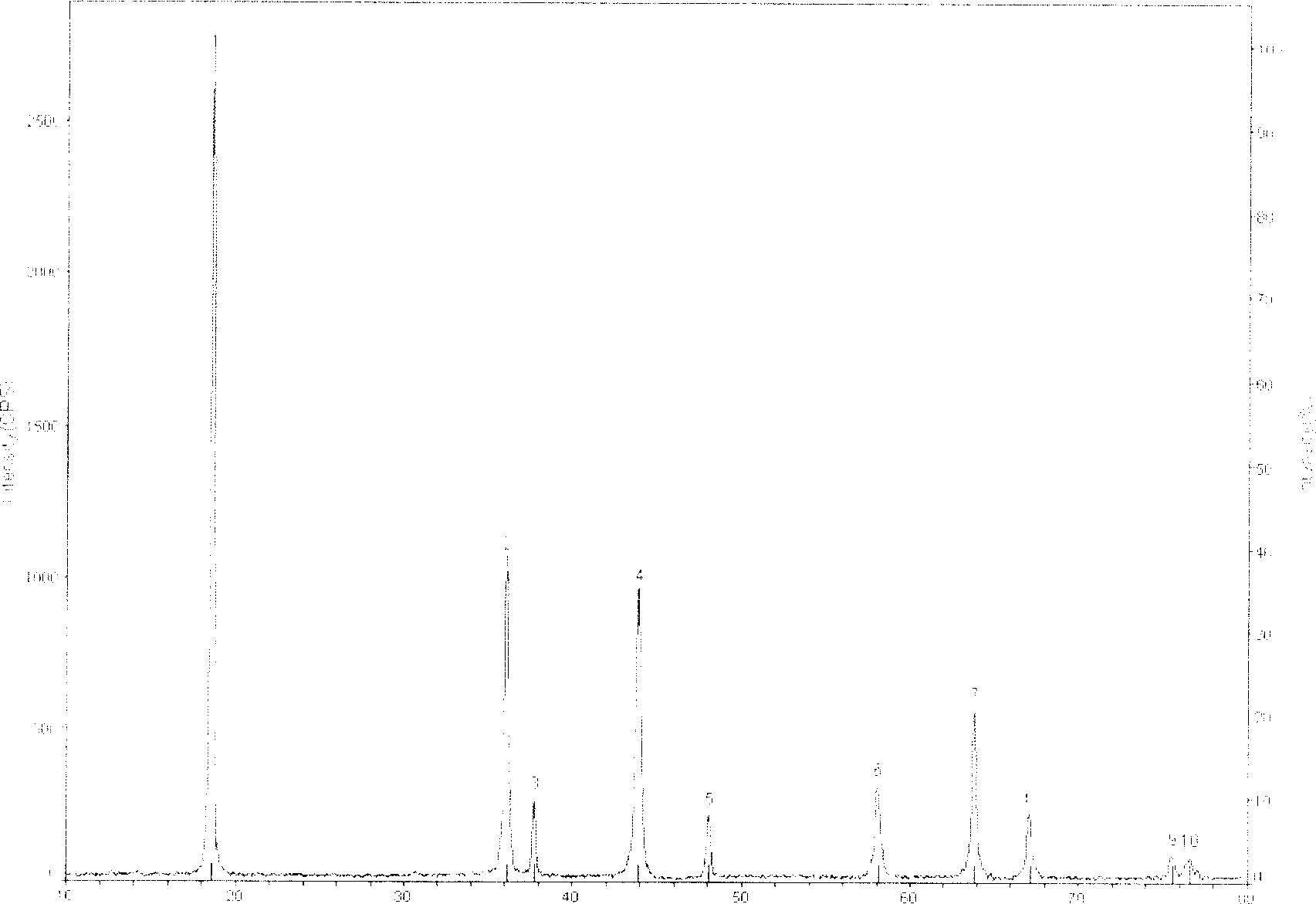

Lithium cell anode material lithium manganate preparing method

A material lithium manganate, lithium-ion battery technology, applied in battery electrodes, chemical instruments and methods, manganate/permanganate, etc., can solve the problem of wide particle size distribution, affecting material battery performance, and uneven composition etc. to achieve excellent electrochemical performance, improved cycle stability, and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

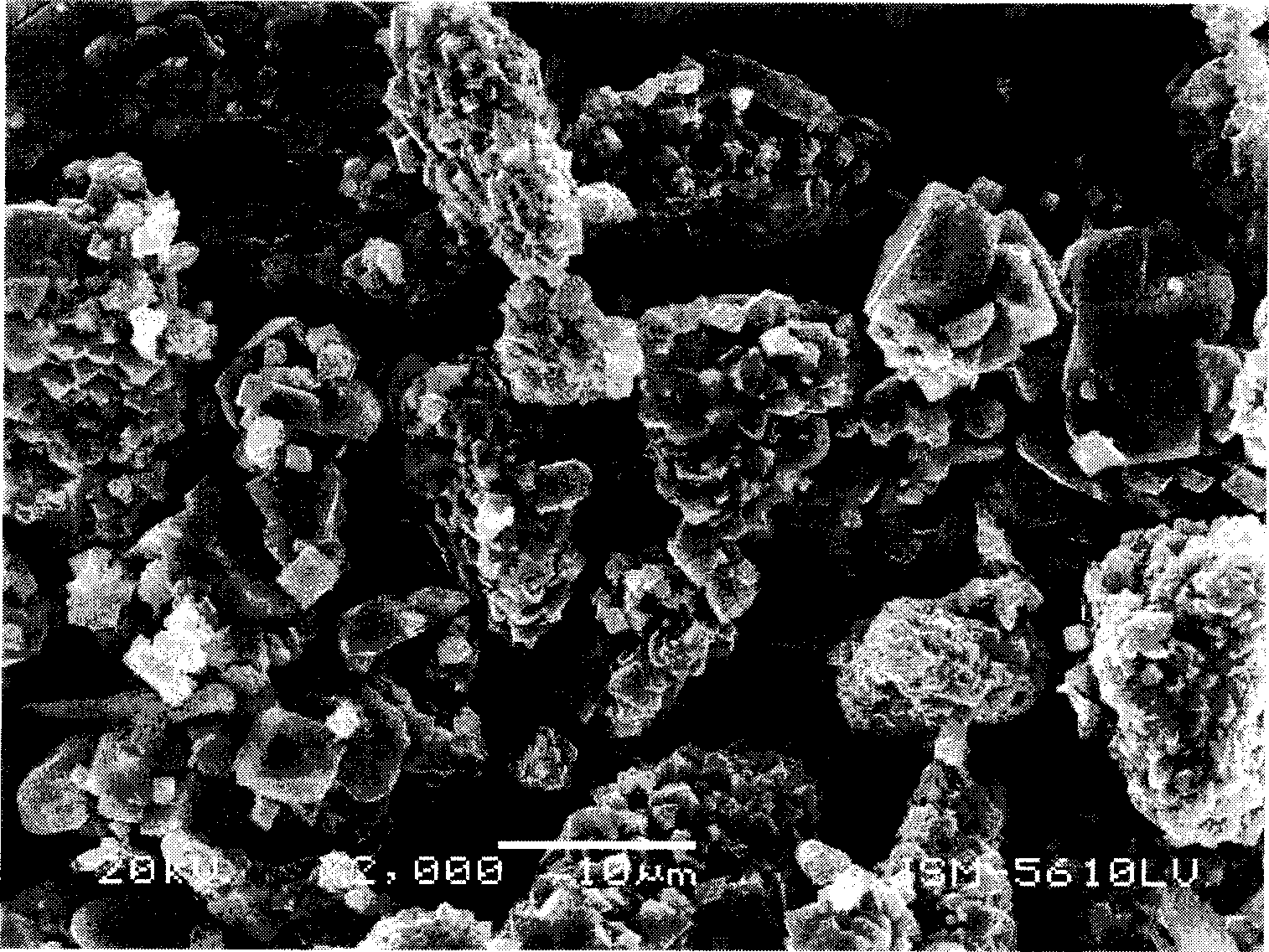

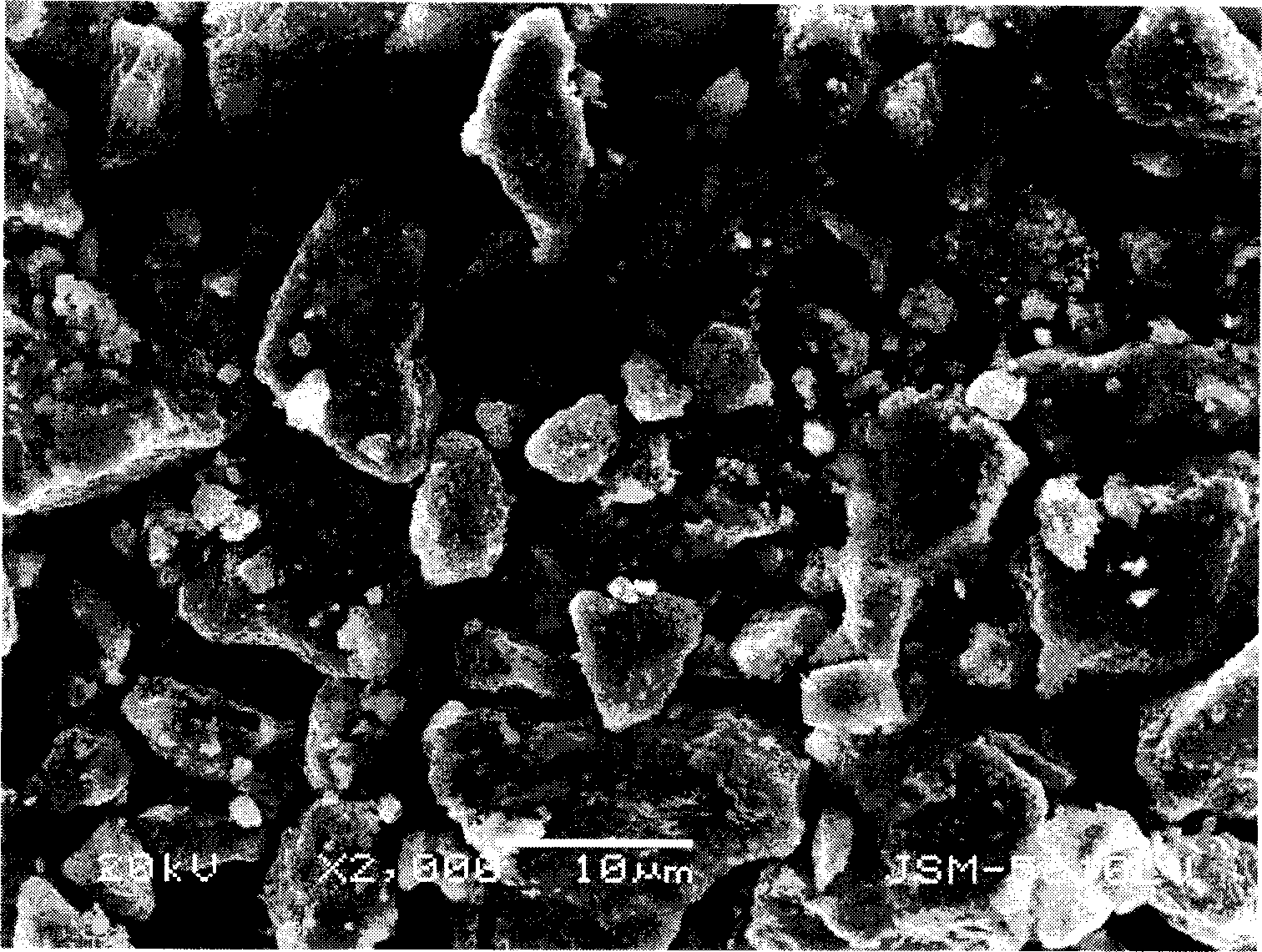

Embodiment 1

[0024] Dissolve 2 grams of polyvinyl alcohol in 100ml of water, add 4.279 grams of LiOH·H 2 O to dissolve it and add 17.388 g of MnO with stirring 2 (Analysis of pure commercial chemical reagents, prepared by electrolysis, the same below), after stirring for another 2 hours, the temperature was raised to 80°C to evaporate the water, and the granulation was stirred and granulated during this process, and the stirring was stopped after the water was evaporated quickly, and placed in 120 Cure in an oven for 6 hours. Put the obtained gel in an alumina crucible, put it into a high-temperature resistance furnace, raise it to 400°C at 10°C / min, keep the temperature constant for 0.5 hours, then raise it to 800°C at 5°C / min, keep the temperature constant for 12 hours, and then follow the furnace Cool to obtain lithium manganate cathode material. The positive electrode material and the lithium counter electrode were assembled into a button cell. The first discharge specific capacity ...

Embodiment 2

[0026] Dissolve 8 grams of polyethylene glycol in 80ml of water, add 3.695 grams of Li 2 CO 3 To dissolve it, add 17.388 g of MnO with stirring 2 After stirring for another 4 hours, the temperature was raised to 70°C to evaporate the water. During this process, the mixture was stirred and granulated, and the stirring was stopped after the water was quickly evaporated, and then placed in an oven at 120°C for 3 hours to solidify. Put the obtained gel in an alumina crucible, put it into a high-temperature resistance furnace, raise it to 400°C at 5°C / min, keep the temperature constant for 0.5 hours, then rise to 700°C at 5°C / min, keep the temperature constant for 12 hours, and then follow the furnace Cool to obtain lithium manganate cathode material. The positive electrode material and the lithium counter electrode were assembled into a button cell. The first discharge specific capacity of the battery was measured to be 120.6mAh / g, and the capacity retention rate after 100 cycl...

Embodiment 3

[0028] Dissolve 4 grams of polyacrylamide in 1000ml of water, add 7.240 grams of LiNO 3 To dissolve it, add 17.388 g of MnO with stirring 2 After stirring for another 4 hours, the temperature was raised to 80°C to evaporate the water. During this process, the mixture was continuously stirred and granulated, and the stirring was stopped after the water was quickly evaporated, and then placed in a 150°C oven for curing for 4 hours. Put the obtained gel in an alumina crucible, put it into a high-temperature resistance furnace, raise it to 450°C at 10°C / min, keep the temperature constant for 0.5 hours, then raise it to 800°C at 5°C / min, keep the temperature constant for 12 hours, and then follow the furnace Cool to obtain lithium manganate cathode material. The positive electrode material and the lithium counter electrode were assembled into a button cell. The first discharge specific capacity of the battery was measured to be 126.2mAh / g, and the capacity retention rate after 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com