Acid-proof and high-temperature resistant alpha-amylase and production thereof

A technology of amylase and high temperature resistance, which is applied in the field of acid-resistant and high-temperature-resistant α-amylase and its preparation. It can solve the problems of α-amylase acid resistance, high temperature resistance and application limitations, and achieve a wide pH range. , the effect of good acid stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Amplification of the Precursor Alpha-Amylase Gene

[0032] Chromosomal DNA of Bacillus licheniformis [China Industrial Microorganism Collection Center (CICC) 10181] was extracted. Design the following primers (the primers are commissioned to be synthesized by Shanghai Bioengineering Co., Ltd.):

[0033] Upstream primer F1: 5'-AGGATCCCTTGAAGAAGTGAAGAAGCAGAGAGG

[0034] Downstream primer R1: 5'-AAAAGCTTCCTGAGGGCTGATGATGACACTTTG

[0035] The 5' end of the upstream primer F1 contains a BamHI restriction site, and the 5' end of the downstream primer R1 contains a HindIII restriction site. Perform PCR amplification using the chromosomal DNA of Bacillus licheniformis 020401 as a template, and mix the components in a sterilized thin-walled centrifuge tube in the following order: Use 50L amplification system: ddH 2 O 41.5L, 10×buffer 5L, dNTP (2.5mmol / L each) 1L, upstream primer F1 (20mol / L) 0.5L, downstream primer R1 (20mol / L) 0.5L, DNA template 1L, TaqDNA polymer...

Embodiment 2

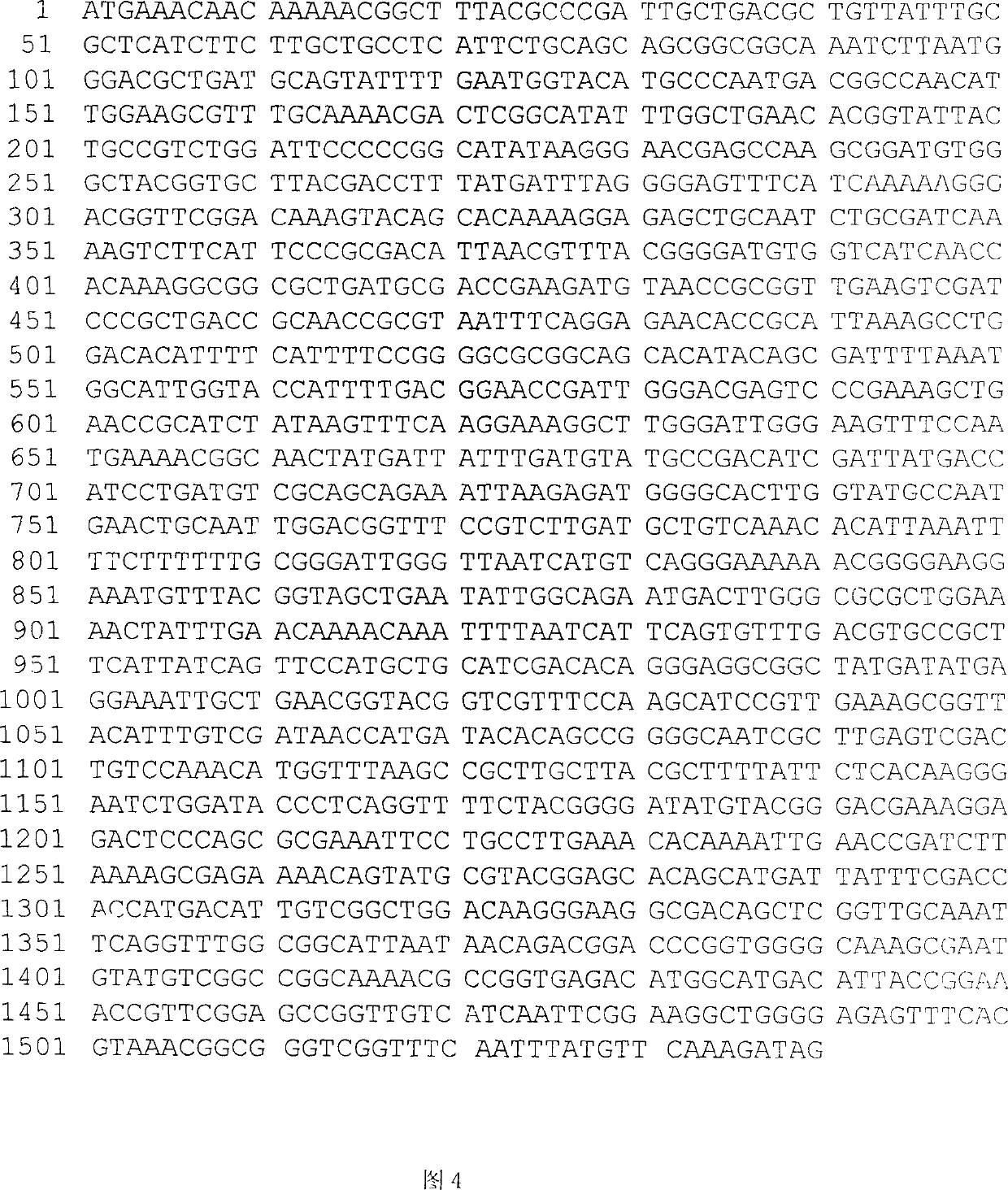

[0036] Example 2: Site-directed mutagenesis of precursor alpha-amylases

[0037] The schematic diagram of the mutation of α-amylase is shown in Fig. 3 . Design overlapping primers as follows:

[0038] Overlap Primer A: 5'-GAGAACACCGCATTAAAGCCTGGAC-3'

[0039] Overlap Primer B: 5'-GTCCAGGCTTTAATGCGGTGTTCTC-3'

[0040] Overlapping primer C: 5'-AAGCATCCGTTGAAAGCGGTTACAT-3'

[0041] Overlapping primer D: 5'-ATGTAACCGCTTTCAACGGATGCTT-3'

[0042] Overlapping primer A is complementary to overlapping primer B, and overlapping primer C is complementary to overlapping primer D. Overlapping primers A and B contained a mutation at amino acid 134, while overlapping primers C and D contained a mutation at amino acid 320. Use the recombinant plasmid pUCA as a template for PCR amplification, and mix the components in a sterilized thin-walled centrifuge tube in the following order: PCR1: use 50 μL amplification system, ddH 2 O 38.5 μL, 10× buffer 5 μL, dNTP (2.5 mmol / L each) 2 μL, upstre...

Embodiment 3

[0043] Embodiment 3: Preparation of expression vector

[0044] Escherichia coli JM109 strain carrying the plasmid pBCH (purchased from Treasure Biotech Co., Ltd.) was inoculated in LB medium containing ampicillin (50 μg / mL), and cultured overnight at 37° C. with shaking. Transfer 1.5 mL of bacterial liquid into a microcentrifuge tube, centrifuge at 12,000 rpm for 30 seconds to collect bacterial cells, discard the supernatant, and empty the residual liquid. Resuspend the pellet in 100 μL of pre-cooled solution I (50 mmol sucrose, 25 mmol Tris, 10 mmol EDTA, pH 8.0), and mix well. Add 200 μL of newly prepared solution II (0.2mol NaOH, 1% SDS), cap the tube tightly, shake gently, and place it on ice for 1-2 minutes until the liquid becomes clear. Add 150 μL of pre-cooled solution III (3 mol potassium acetate, pH 4.8), gently rotate the centrifuge tube to mix solution III evenly in the viscous bacterial lysate, and place it on ice for 3-5 minutes. Centrifuge at 12,000 rpm for 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com