Method for producing soymilk of removed anti-nutrition factor type

An anti-nutritional factor and production method technology, applied in the field of production technology of high-quality soybean milk, can solve the problems of unsatisfactory removal of trypsin inhibitor, undisclosed complex enzyme composition or composition, complicated process, etc., and achieves reduction of production cost and simple steps. , good taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] For commercially available soybeans, select high-quality soybeans through a sorting machine, wash them 2-3 times, soak the washed soybeans in 3 times the volume of water, soak for 8-24 hours, and soak at a temperature of 15-20°C.

[0037] The soaked soybeans are added to NaHCO at a mass ratio of about 0.25% 3 , boiled in 85-90°C hot water for 1.5-4.5 minutes, then cooled and peeled, the peeled soybeans were ground into a slurry with a refiner and an ultrafine mill, and the bean dregs were discarded.

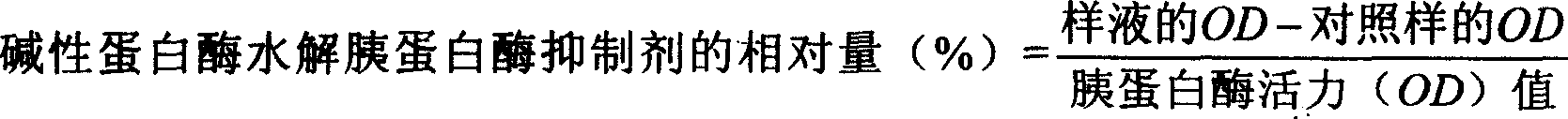

[0038]Adding the superfinely pulverized soybean milk slurry into a biological reaction tank, and then adding alkaline protease. After reacting at 60°C for 2-2.5 hours, the temperature was raised rapidly to 100°C and kept for 5 minutes. The amount of alkaline protease added is to add 0.085 activity units of alkaline protease per gram of soybean protein in the soybean milk slurry.

[0039] The heated soybean milk is centrifuged at 3000 rpm to remove the precipitate, the sl...

Embodiment 2

[0044] The process of selecting and cleaning soybeans, soaking, boiling, refining, superfine grinding, enzymatic engineering treatment, separating pulp and slag, and colloid grinding is the same as in Example 1.

[0045] After the soybean milk is ultrafinely pulverized by a colloid mill, it is then mixed with dissolved white sugar, milk powder, and sodium chloride in a blending mixing tank, and taurine, vitamin C, and calcium chloride are added, and stirred for 10 minutes to obtain a blended A good health drink is stirred for 10 minutes to obtain a prepared soybean milk drink.

[0046] Then the soy milk is homogenized through 80MPa and 40MPa homogenizers respectively, and then the homogenized soy milk is passed into a vacuum tank, pumped at 80kPa for 10 minutes, and finally the soy milk is passed into a 138°C ultra-high temperature instant sterilizer Sterilize for 8-12 seconds.

[0047] The obtained soybean milk product is filled, subjected to quality inspection, physical and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com