Method for preparing high activity titanium dioxide sol using industrial metatitanic acid as material

A technology of titanium dioxide and metatitanic acid, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of high price and serious pollution, and achieve low price, wide source and strong adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

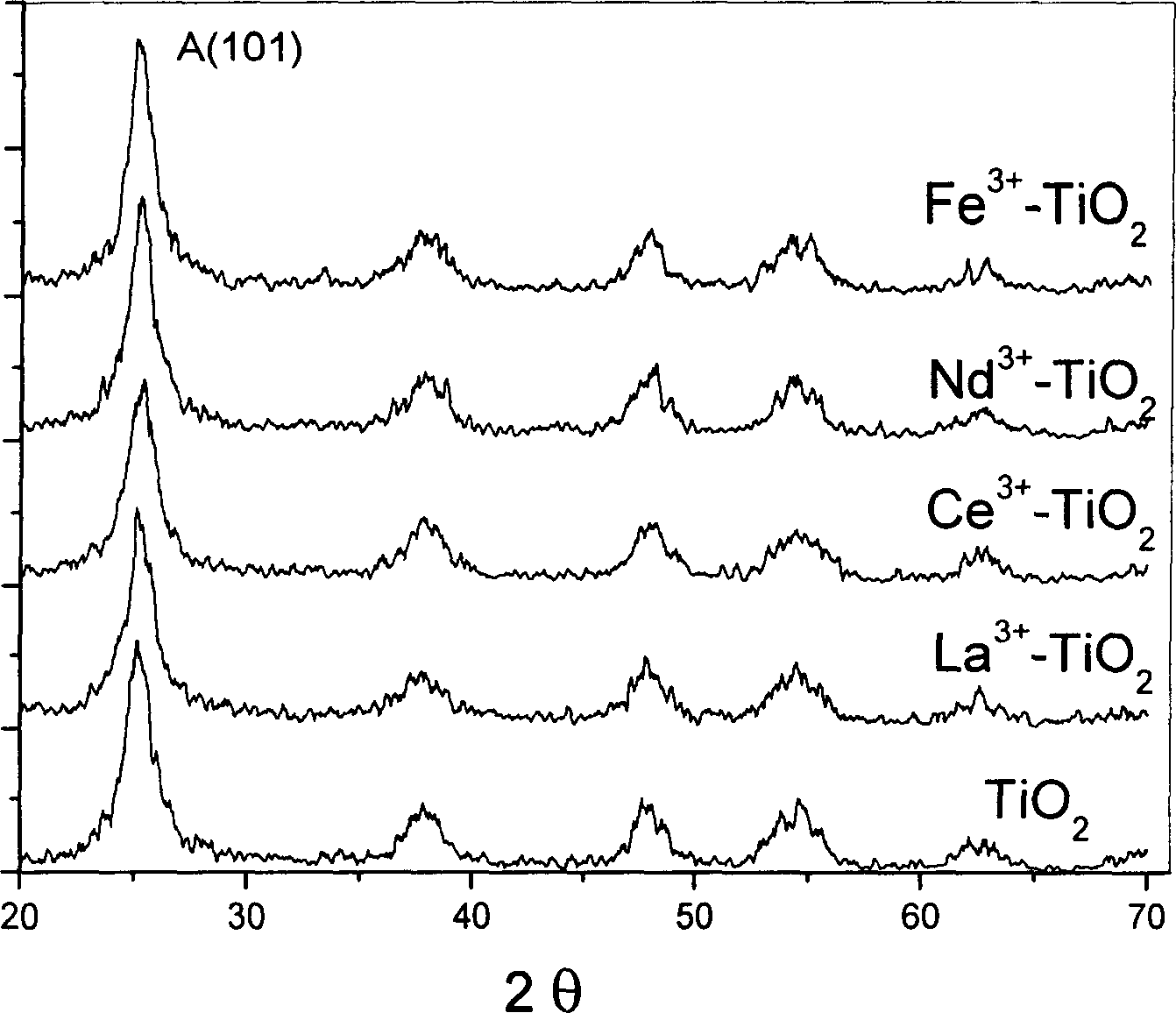

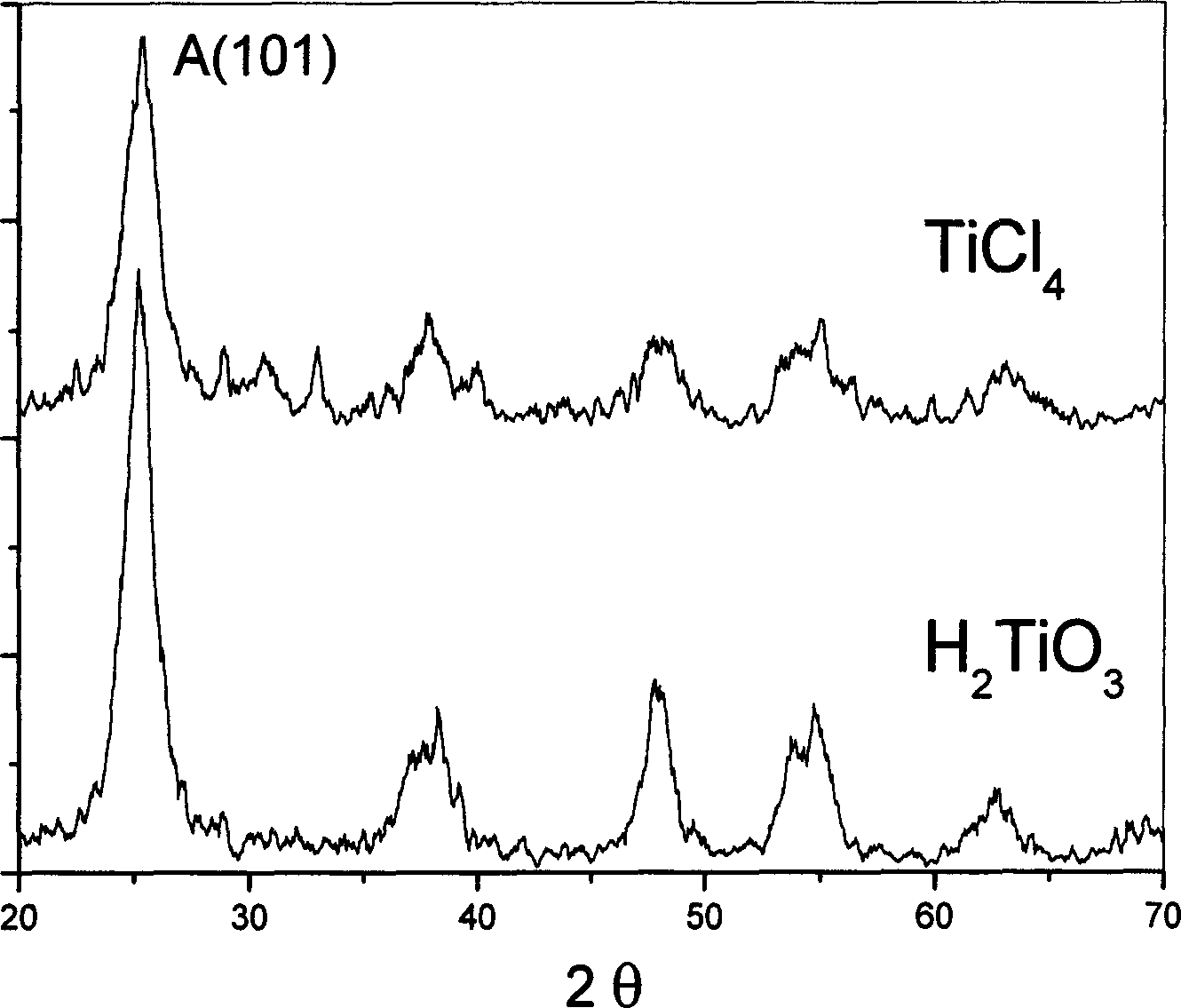

[0039] Example 1. Prepare high-purity titanium dioxide sol with industrial metatitanic acid (provided by Panzhihua Iron and Steel Plant, the same below) as raw material

[0040] Weigh 100g of industrial metatitanic acid as it is, add water and mix evenly, add excess ammonia water dropwise to adjust the pH to above 8, heat and stir at below 40°C for 3 hours, then repeatedly filter and wash until there is no sulfate ion (use 0.5M barium chloride solution Titration detection); beat the washed filter cake again, then drop excess ammonia water to adjust the pH to above 8, heat and stir at below 40°C for 2 hours, then repeatedly filter and wash until no sulfate ion is detected (with 0.5M chloride barium solution titration detection), and then repeatedly washed with distilled water to neutrality, so that the impurity ions can be basically removed, and finally the slurry is mixed with water and beaten, then the slurry is mixed with water, and 200ml of 10% Nitric acid solution, so that...

example 2

[0041] Example 2. Prepare cerium-doped titania sol with industrial metatitanic acid as raw material

[0042] Weigh 90g of industrial metatitanic acid as it is, add water to make a slurry and mix evenly, take 2.3g of cerium nitrate to dissolve, then add it to the metatitanic acid slurry and mix evenly; add excess ammonia water to adjust the pH to above 9, heat and stir at below 40°C for 3 hours , and then repeatedly filter and wash until there is no sulfate ion (detected by titration with 0.5M barium chloride solution); beat the washed filter cake again, then add excess ammonia water dropwise to adjust the pH to above 8, and heat and stir at below 40°C for 2 hours , then repeatedly filtered and washed until no sulfate ions are detected (detected by titration with 0.5M barium chloride solution), and then repeatedly washed with distilled water until neutral, so that the impurity ions can be basically removed. Finally, the slurry is mixed with water and beaten. Then mix the slurr...

example 3

[0043] Example 3. Prepare lanthanum-doped titania sol with industrial metatitanic acid as raw material

[0044] Weigh 110g of industrial metatitanic acid as it is, add water to beat and mix evenly, take 2.7g of lanthanum nitrate to dissolve, then add to the metatitanic acid slurry and mix evenly; add excess sodium hydroxide solution dropwise to adjust the pH to above 10, and heat below 40°C Stir for 2 hours, then repeatedly filter and wash until there is no sulfate ion (detected by titration with 0.5M barium chloride solution); then add excess sodium hydroxide solution dropwise to adjust the pH to above 9, heat and stir at below 40°C for 2 hours, and then Repeatedly filter and wash...and repeat until no sulfate ion is detected after adding sodium hydroxide solution for washing (detected by titration with 0.5M barium chloride solution), and then repeatedly wash with distilled water until neutral, so that the impurity ions can be removed Basically remove it. Finally, the slurry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com