Method for preparing nano silicon dioxide-acrylate polymeric microball material

A technology of nano-silica and polymer microspheres, which is applied in the field of preparation of oil-soluble nano-silica-acrylate polymer microsphere materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

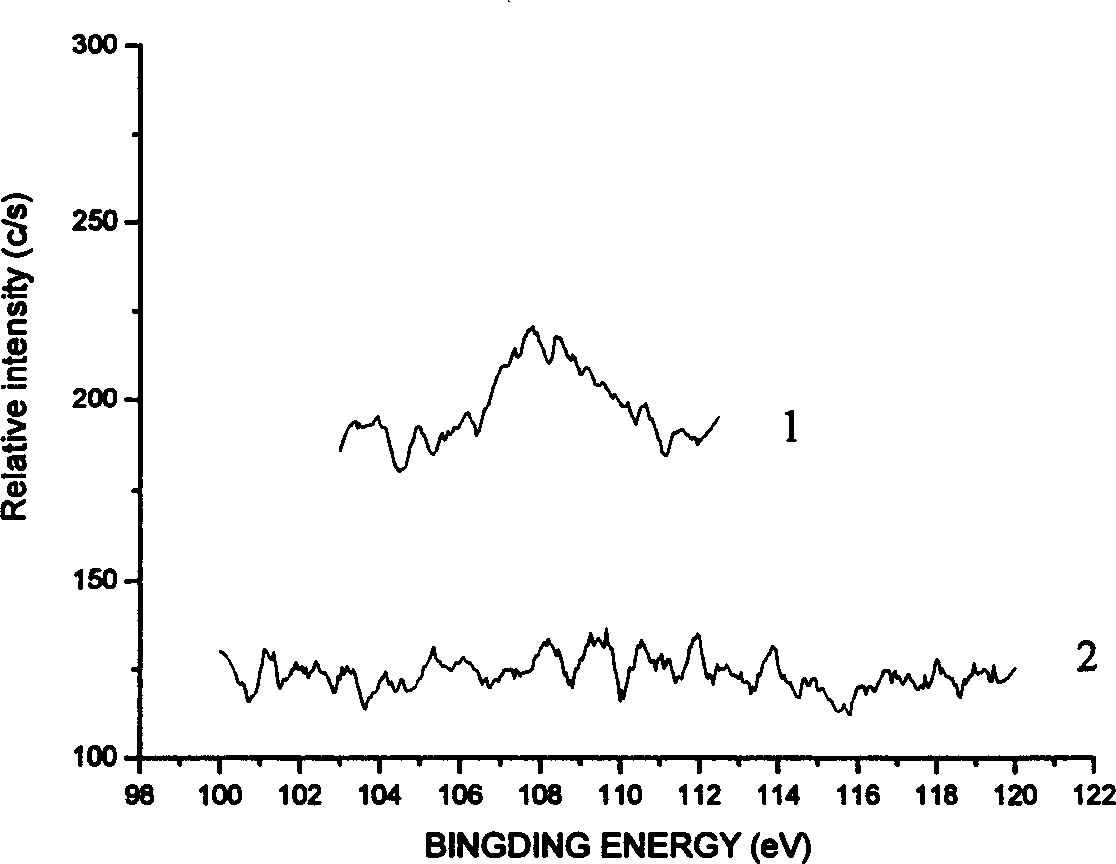

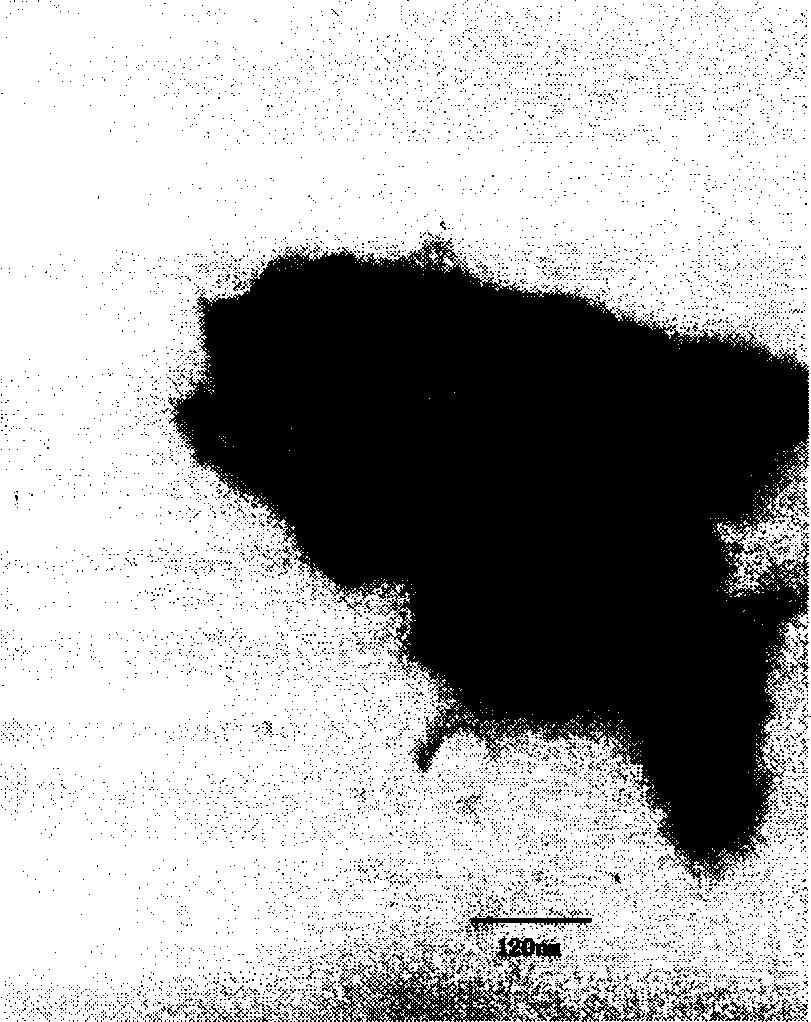

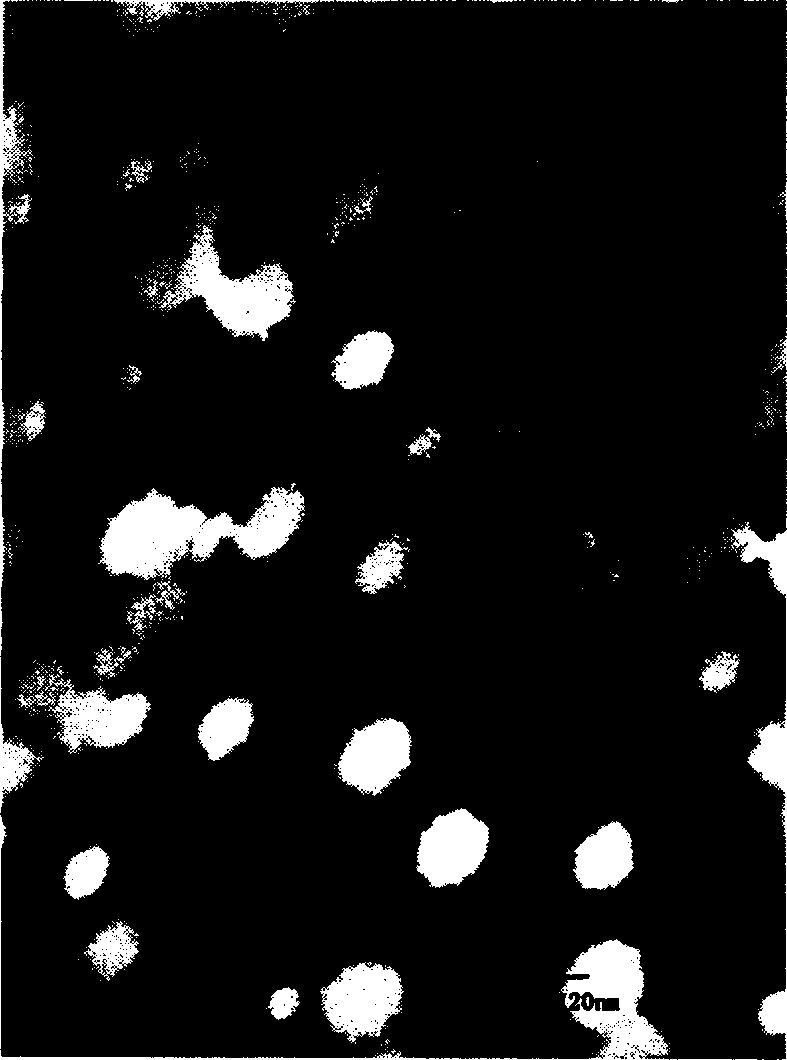

Image

Examples

Embodiment 1

[0024] A preparation method of an oil-soluble nano silicon dioxide-acrylate polymer microsphere material, comprising the following steps:

[0025] The first step: add 10-100 parts by mass of oil-soluble silica to 10-100 parts by mass of acrylate monomer, and then ultrasonically disperse for 1-30 minutes to form a mixed solution.

[0026] In this embodiment, the oil-soluble nano silica refers to the silica produced by Degussa Company, numbered R-974, the particle size is 12nm, and the mass parts can be 10 parts, 20 parts, 32 parts, 45 parts, 52 parts parts, 70 parts, 81 parts, 90 parts. The acrylate monomer can be methyl acrylate monomer, ethyl acrylate monomer, octyl acrylate monomer, isooctyl acrylate monomer, methyl methacrylate monomer, hydroxyethyl methacrylate monomer, methyl acrylate One or more mixtures of hydroxypropyl acrylate monomer, hydroxyethyl acrylate monomer, hydroxypropyl acrylate monomer, and glycidyl methacrylate monomer. The mixture ratio can be any ratio ...

Embodiment 2

[0031] (1) Dispersion of oil-soluble nano-silica in the monomer:

[0032] Step 1: Add 0.5g of oil-soluble silicon dioxide to 20 / 20g of methyl methacrylate / butyl methacrylate monomer, and then perform ultrasonic dispersion to obtain a mixed liquid. The ultrasonic dispersion conditions are as follows: the ultrasonic frequency is 200 kHz, the ultrasonic power is 1000 W, and the ultrasonic emulsification time is 10 min.

[0033] The second step: add 2.0g n-hexadecane and 0.4g azobisisobutyronitrile into the mixed liquid, add 1.5g sodium lauryl sulfate into 100g water and stir to dissolve it, then mix the mixed liquid with twelve An aqueous solution of sodium alkyl sulfate was mixed and stirred, and ultrasonically emulsified. The phacoemulsification conditions of the miniemulsion are: the ultrasonic frequency is 200kHz, the ultrasonic power is 500W, and the phacoemulsification time is 5min.

[0034] Step 3: raise the temperature to a specified temperature of 60° C., and then init...

Embodiment 3

[0044] Step 1: Add 1g of oil-soluble silica to 20 / 20g of methyl methacrylate / butyl methacrylate monomer, and then perform ultrasonic dispersion. Ultrasonic dispersion conditions are: ultrasonic frequency 300kHz, ultrasonic power 800W, phacoemulsification time 8min.

[0045] Step 2: Add 0.8g of n-hexadecane and 0.2g of benzoyl peroxide into the mixed liquid, add 1.2g of sodium lauryl sulfate into 140g of water and stir to dissolve it, then mix the mixed liquid with dodecane Sodium sulfate aqueous solution was mixed and stirred, and ultrasonically emulsified. The phacoemulsification conditions of the miniemulsion are: the ultrasonic frequency is 200kHz, the ultrasonic power is 1000W, and the phacoemulsification time is 5min.

[0046] Step 3: raise the temperature to a specified temperature of 70° C., and then initiate polymerization to obtain an oil-soluble silica-acrylate composite miniemulsion. Proportion:

[0047] A oil-soluble nano-silica 1 g

[0048] B Butyl methacrylat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com