Self assembly chemical silver plating method on non metal material surface

A non-metallic material, chemical silver plating technology, applied in the direction of metal material coating process, liquid chemical plating, coating, etc., can solve the problems of troublesome operation and difficult reaction, and achieve low cost, simple method and strong binding force high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

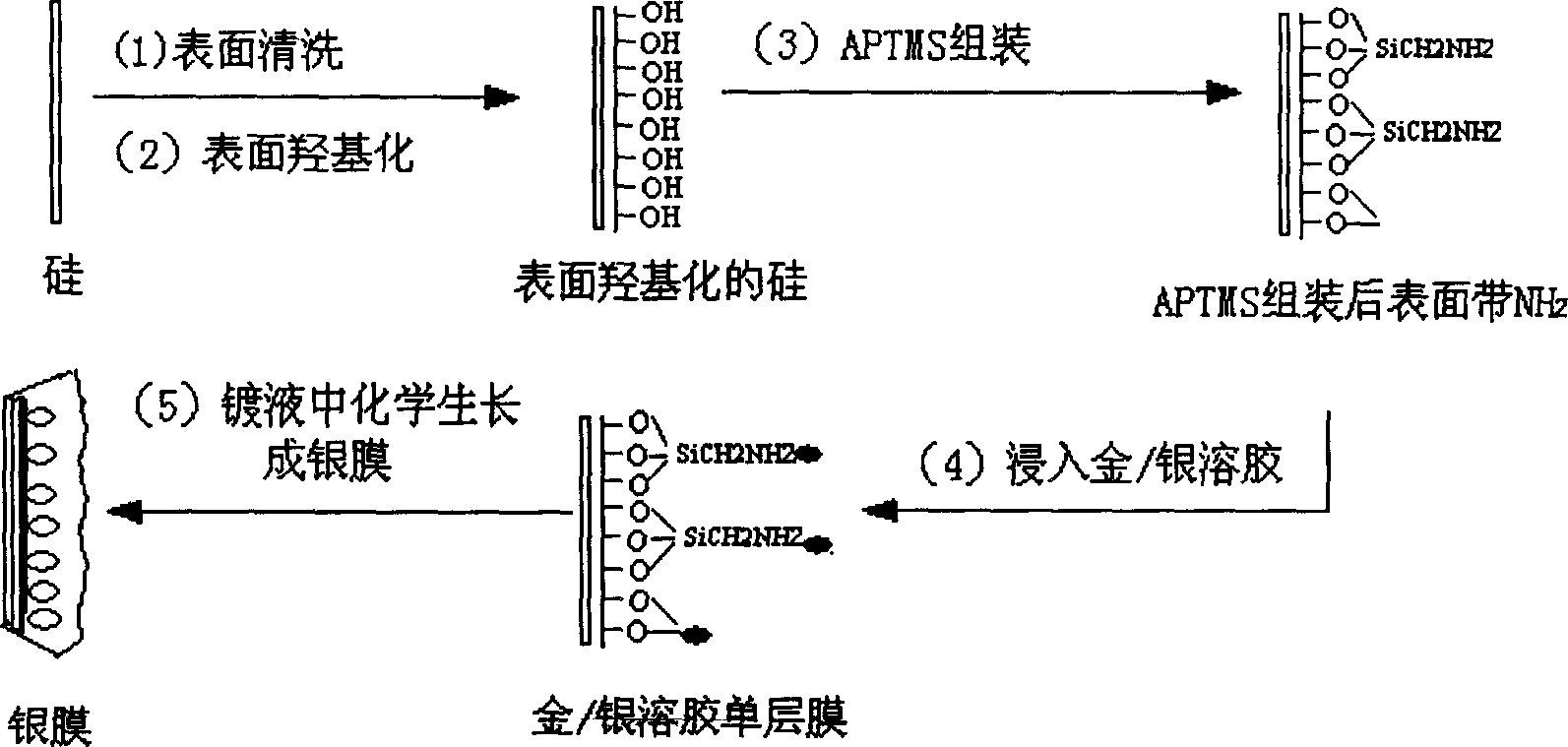

[0018] Embodiment 1. Electroless silver plating on silicon wafer

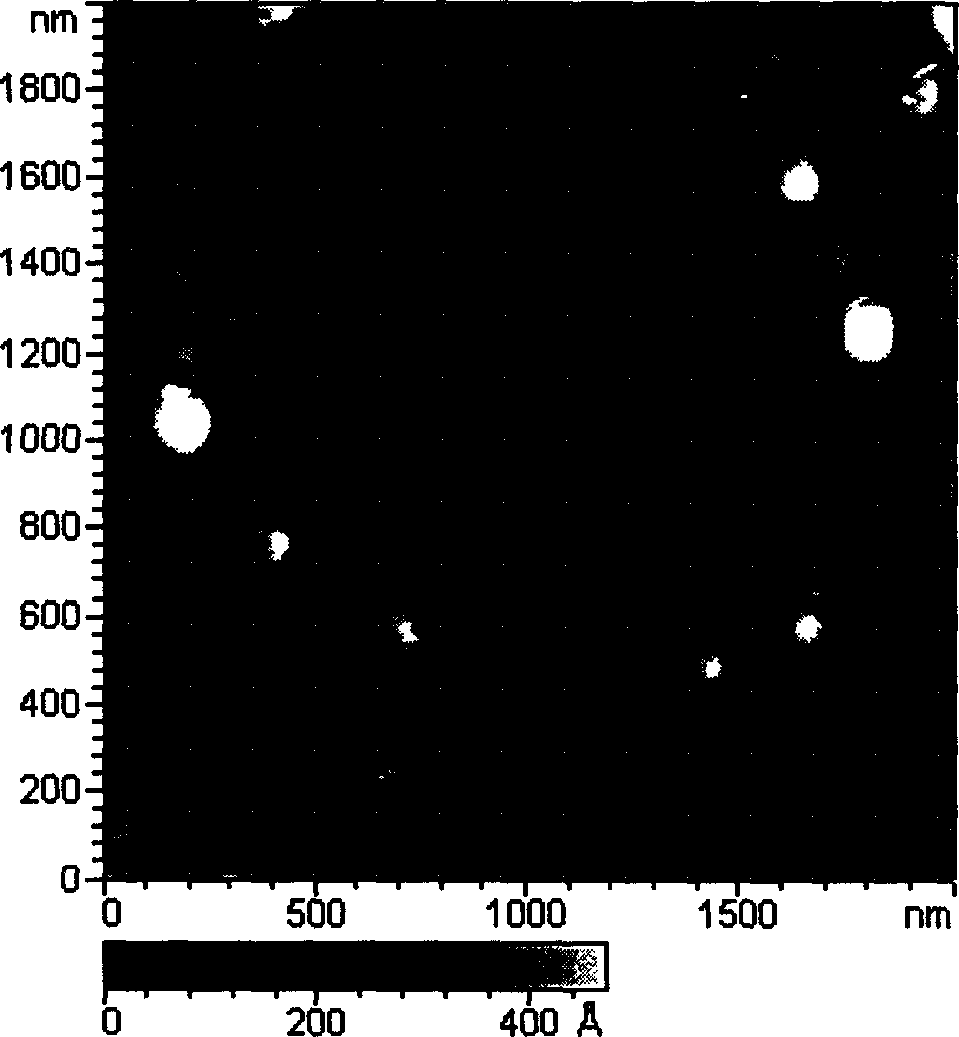

[0019] The monocrystalline silicon wafer (5-10Ωcm -1 ) after surface cleaning, carry out surface hydroxylation (30 minutes) in sulfuric acid hydrogen peroxide (volume ratio is 7: 3) mixed solution, then put into 1-10% APTMS (aminopropyltrimethoxysilane) aqueous solution and soak 1- 10h, after rinsing, immerse in gold or silver sol with a particle size of about 2-30nm for 1-10h, and finally perform electroless plating in the mixed plating solution.

[0020] Preparation of gold or silver sol: 1mL mass (g) volume (ml) fraction of 1% AuCl 3 ·HCl or AgNO 3 The aqueous solution was added to 100 mL of ultrapure water, and 1 mL of an aqueous solution of trisodium citrate with a mass volume fraction of 1% was added dropwise under continuous magnetic stirring. Then slowly add 1 mL of an aqueous solution containing 0.07-0.09% sodium borohydride and 1% trisodium citrate dropwise, and then stir for 1 hour after completio...

Embodiment 2

[0022] Embodiment 2 Electroless silver plating on titanium dioxide sheet

[0023] Clean the titanium dioxide sheet (or the titanium sheet with the titanium dioxide oxide film on its surface) and calcinate it in a muffler furnace at 600-800°C for 0.5-1 hour, then soak it in 1-10% APTMS aqueous solution for 1-10 hours After rinsing, put the silver sol with a particle size of 10-30nm for 1-10 hours, and finally perform electroless plating in the mixed plating solution. Wherein, the preparation of silver sol and electroless plating solution is the same as Example 1.

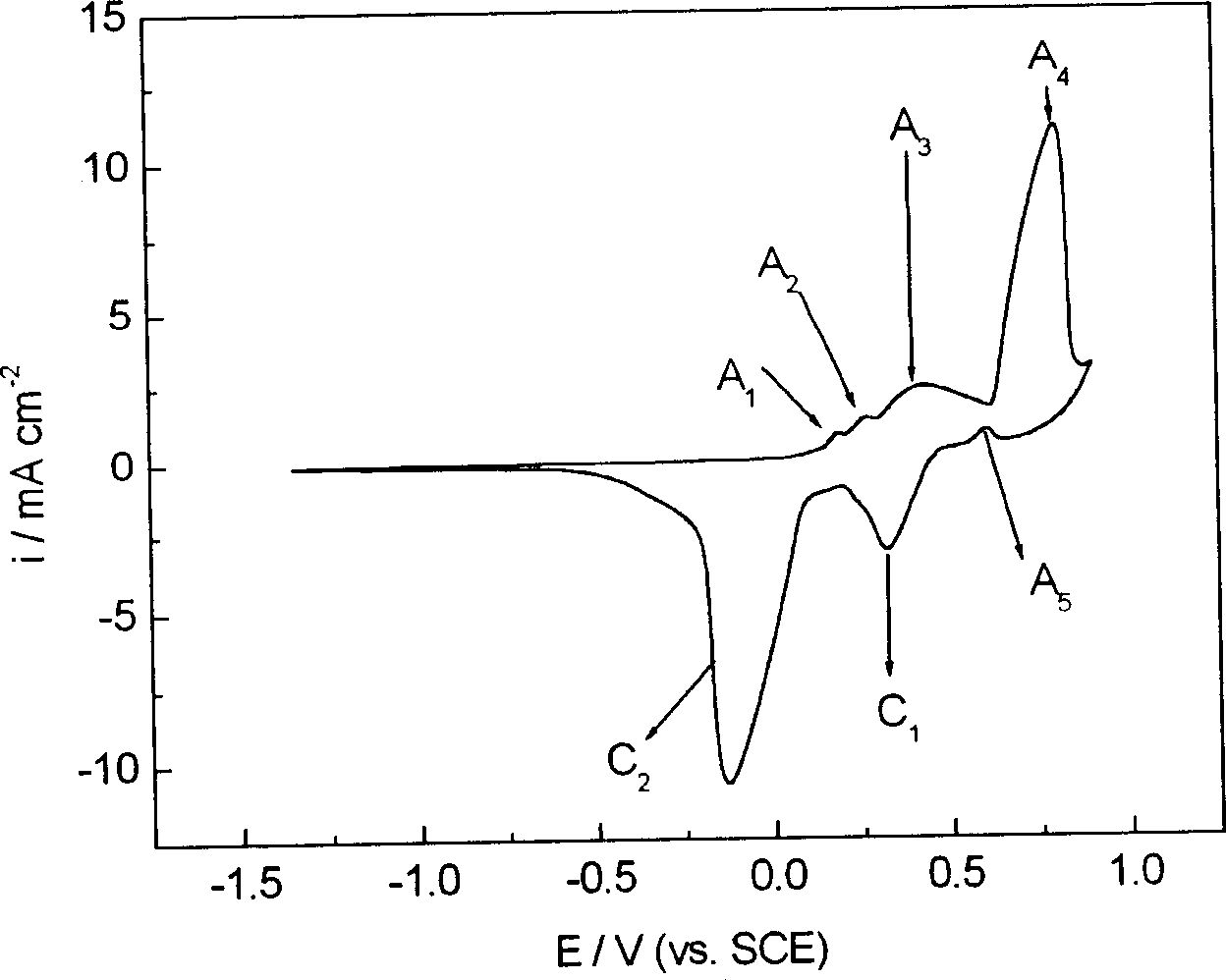

[0024] The silver film obtained by the two embodiments has very strong binding force to the substrate, good electrochemical properties, and has image 3 properties shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com