Polymer microporous modification by corona induced grafting technology

A technology of inducing grafting and grafting polymerization, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of reducing membrane separation performance and mechanical strength, destroying the structure of membrane body, and difficult to continuous application. , to achieve the effect of broadening the scope of application, less damage, and reduced protein adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056]20 lengths of 10cm polyethylene (PE) hollow fiber microporous membranes (average aperture 0.85 micron, developed by Hangzhou Zhejiang University Kaihua Membrane Technology Co., Ltd.) were weighed and fixed on the corona stand of the corona treater for processing. The conditions are: dry air filling rate 5L / min; treatment temperature 26°C (room temperature); corona power 0.5kW. The treated PE hollow fiber membrane was immersed in an aqueous solution of acrylic acid (AA), and grafted at 30°C. During the reaction, N 2 Deoxygenation. When the set reaction time is reached, the PE hollow fiber is taken out, and the membrane is repeatedly ultrasonically soaked and cleaned with 20°C pure water and ethanol for 24 hours to remove unreacted monomers and homopolymers, and then weighed after vacuum drying at 60°C for 24 hours. weight and representation.

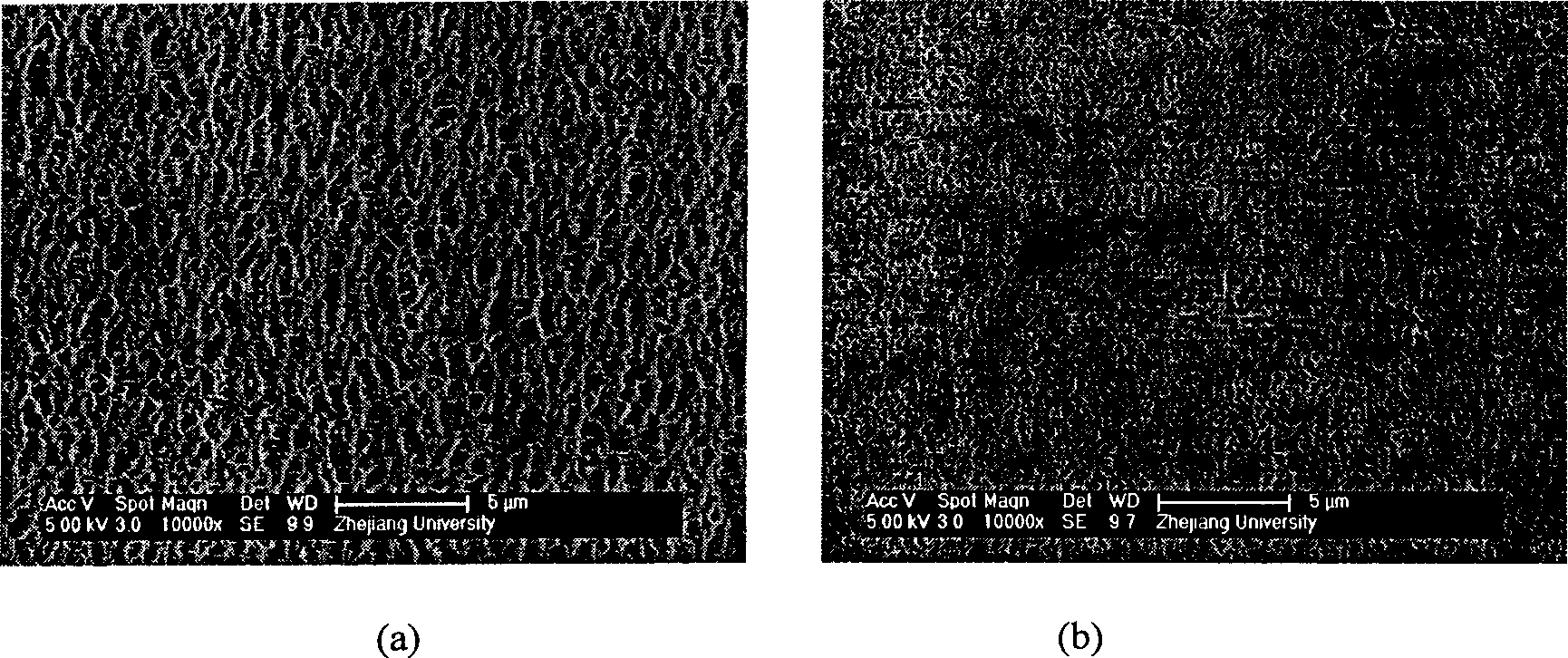

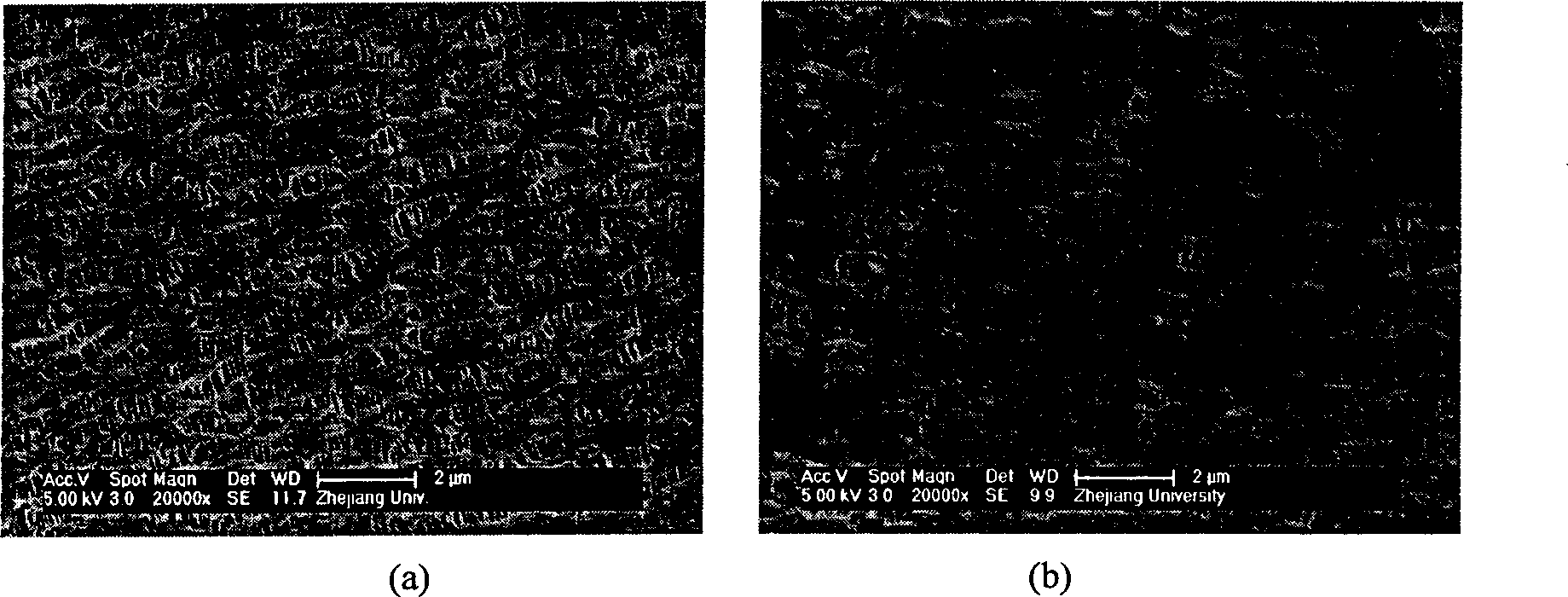

[0057] The scanning electron microscope (SEM) photos of the outer surface morphology of PE hollow fiber microporous membranes be...

Embodiment 2

[0060] Cut, wash and dry polypropylene (PP) flat microporous membrane (average pore size 0.22 micron, produced by Membrana, Germany) 4 × 8cm 2 , corona treatment after weighing, the treatment conditions are: dry air filling rate 30L / min; treatment temperature 10 ℃ (room temperature); discharge voltage 2.0kW. The film after corona treatment was immersed in the ethanol solution of propylene acetate, and the grafting reaction was carried out at 70 ° C. During the reaction, nitrogen saturated with water vapor was continuously passed into the reaction solution. 2 . When the set reaction time is reached, the PP flat film is soaked in 2.0wt% sodium hydroxide aqueous solution at 40°C for 3 hours, 1.5wt% hydrochloric acid aqueous solution at 30°C for 2 hours, and then soaked in water at 60°C for 48 hours. Then carry out with water, after vacuum drying at 10°C, carry out weighing and characterization.

[0061] The performance characterization data of the PP flat microporous membrane ...

Embodiment 3

[0064] 20 PP hollow fiber microporous membranes with a length of 10 cm (average pore size 0.15 micron, produced by Hangzhou Zheda Kaihua Membrane Technology Co., Ltd.) were cut and weighed after cleaning and drying. The corona treatment conditions were the same as in Example 1. The treated PP hollow fiber membrane was immersed in N-vinylpyrrolidone (NVP) aqueous solution, and grafted at 75 ° C. During the reaction, N 2 Deoxygenation. When the set reaction time is reached, the PP hollow fiber is taken out, and the membrane is repeatedly ultrasonically cleaned with pure water and ethanol to remove unreacted monomers and homopolymers, and then weighed and characterized after vacuum drying at 50°C for 24 hours .

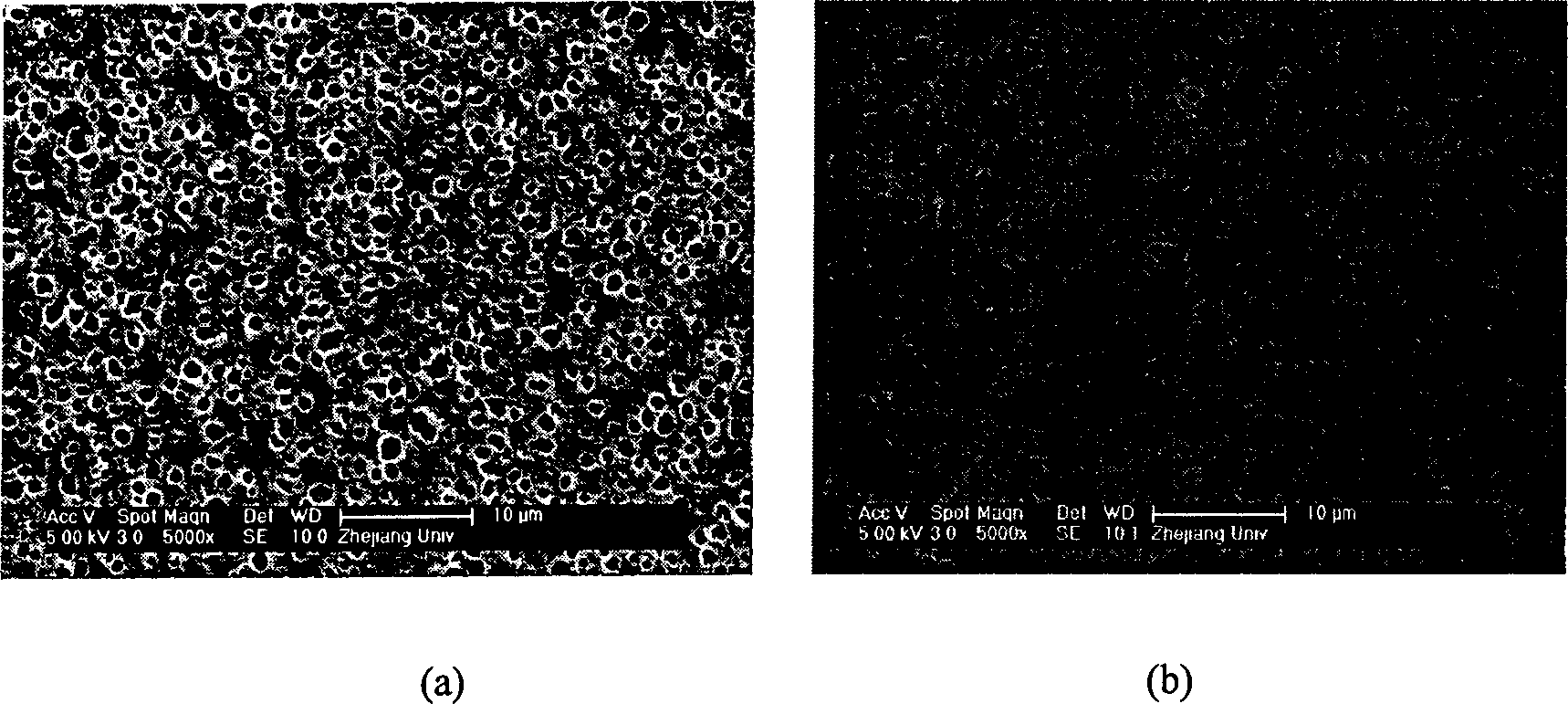

[0065] The performance characterization data of the PP hollow fiber membrane and the original membrane reference substance after grafting NVP on the surface are shown in Table 3, and the SEM images of the outer surface morphology of the membrane before and after graftin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com